Showing Spotlights 121 - 128 of 252 in category All (newest first):

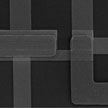

Most of the accomplishments in building carbon nanotube circuits have come at the single-nanotube level. Researchers have been struggling with two major obstacles in building CNT-based circuits: the presence of metallic CNTs and a 'perfect' alignment of nanotubes. In new work, researchers have now demonstrated the ability to fabricate, in a scalable manner, larger-scale CNFET circuits at highly scaled technology nodes. The channel lengths are ranging from 90 nm to sub-20 nm.

Most of the accomplishments in building carbon nanotube circuits have come at the single-nanotube level. Researchers have been struggling with two major obstacles in building CNT-based circuits: the presence of metallic CNTs and a 'perfect' alignment of nanotubes. In new work, researchers have now demonstrated the ability to fabricate, in a scalable manner, larger-scale CNFET circuits at highly scaled technology nodes. The channel lengths are ranging from 90 nm to sub-20 nm.

Apr 29th, 2014

Scientists have great expectations that nanotechnologies will bring them closer to the goal of creating computer systems that can simulate and emulate the brain's abilities for sensation, perception, action, interaction and cognition while rivaling its low power consumption and compact size - basically a brain-on-a-chip. Already, scientists are working hard on laying the foundations for what is called neuromorphic engineering - a new interdisciplinary discipline that includes nanotechnologies and whose goal is to design artificial neural systems with physical architectures similar to biological nervous systems.

Scientists have great expectations that nanotechnologies will bring them closer to the goal of creating computer systems that can simulate and emulate the brain's abilities for sensation, perception, action, interaction and cognition while rivaling its low power consumption and compact size - basically a brain-on-a-chip. Already, scientists are working hard on laying the foundations for what is called neuromorphic engineering - a new interdisciplinary discipline that includes nanotechnologies and whose goal is to design artificial neural systems with physical architectures similar to biological nervous systems.

Apr 4th, 2014

Stretchable energy storage and conversion devices are key components for the fabrication of complete and independent stretchable systems. A recent review summarizes the recent progresses in the developments of stretchable power sources including supercapacitors, batteries and solar cells. It discusses representative structural and material designs to impart stretchability to the originally rigid devices and analyze advantages and drawbacks associated with the various fabrication methods. It also presents summaries of the research progresses along with future development directions.

Stretchable energy storage and conversion devices are key components for the fabrication of complete and independent stretchable systems. A recent review summarizes the recent progresses in the developments of stretchable power sources including supercapacitors, batteries and solar cells. It discusses representative structural and material designs to impart stretchability to the originally rigid devices and analyze advantages and drawbacks associated with the various fabrication methods. It also presents summaries of the research progresses along with future development directions.

Mar 20th, 2014

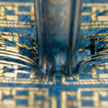

Flexible electronics is a rising field in terms of research and potential application opportunities to obtain similar characteristics than today's prevailing rigid electronics components. In new work, researchers have demonstrated the semiconductor industry's most advanced device architecture - FinFET, a new generation of device architecture which Intel has adopted in 2011 in their microprocessors; these field effect transistors offer non-planar three-dimensional topology where the channels are vertically aligned in arrays of ultra-thin silicon fins bordered by multiple gates - in a flexible platform using only industry standard processes and keeping the advantages offered by silicon.

Flexible electronics is a rising field in terms of research and potential application opportunities to obtain similar characteristics than today's prevailing rigid electronics components. In new work, researchers have demonstrated the semiconductor industry's most advanced device architecture - FinFET, a new generation of device architecture which Intel has adopted in 2011 in their microprocessors; these field effect transistors offer non-planar three-dimensional topology where the channels are vertically aligned in arrays of ultra-thin silicon fins bordered by multiple gates - in a flexible platform using only industry standard processes and keeping the advantages offered by silicon.

Mar 11th, 2014

The term printed electronics refers to the application of printing technologies for the fabrication of electronic circuits and devices, increasingly on flexible plastic or paper substrates. Traditionally, electronic devices are mainly manufactured by photolithography, vacuum deposition, and electroless plating processes. In contrast to these multistaged, expensive, and wasteful methods, inkjet printing offers a rapid and cheap way of printing electrical circuits with commodity inkjet printers and off-the-shelf materials.

The term printed electronics refers to the application of printing technologies for the fabrication of electronic circuits and devices, increasingly on flexible plastic or paper substrates. Traditionally, electronic devices are mainly manufactured by photolithography, vacuum deposition, and electroless plating processes. In contrast to these multistaged, expensive, and wasteful methods, inkjet printing offers a rapid and cheap way of printing electrical circuits with commodity inkjet printers and off-the-shelf materials.

Feb 27th, 2014

Researchers have developed a low-cost generic batch process using a state-of-the-art CMOS process to transform conventional silicon electronics into flexible and transparent electronics while retaining its high-performance, ultra-large-scale-integration density and cost. This process relies on standard and cheap silicon (100) wafer and microfabrication techniques, which allows to fabricate high performing devices. Furthermore, it allows the recyclability of the wafer to produce several substrates with devices, making it economically attractive.

Researchers have developed a low-cost generic batch process using a state-of-the-art CMOS process to transform conventional silicon electronics into flexible and transparent electronics while retaining its high-performance, ultra-large-scale-integration density and cost. This process relies on standard and cheap silicon (100) wafer and microfabrication techniques, which allows to fabricate high performing devices. Furthermore, it allows the recyclability of the wafer to produce several substrates with devices, making it economically attractive.

Feb 11th, 2014

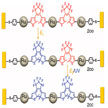

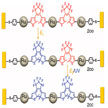

External stimuli, such as light, mechanical force, magnetic field, electrical field and electrochemical potential, are all driving forces that can be utilized to modulate the structure or conformation of molecules, and therefore to affect the performance of functional molecular devices. In new work, researchers take advantage of synergetic modulation by multiple external controls to explore multi-modulable molecular devices with the help of chemical tailoring, which have not been addressed so far.

External stimuli, such as light, mechanical force, magnetic field, electrical field and electrochemical potential, are all driving forces that can be utilized to modulate the structure or conformation of molecules, and therefore to affect the performance of functional molecular devices. In new work, researchers take advantage of synergetic modulation by multiple external controls to explore multi-modulable molecular devices with the help of chemical tailoring, which have not been addressed so far.

Jan 8th, 2014

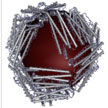

Researchers demonstrate a strategy for the fabrication of memristive nanodevices with stable and tunable performance by assembling ferritin monolayer inside a on-wire lithography-generated 12 nm gap. This work work uses the unique high iron loading capacity of Archaeoglobus fulgidus ferritin. The iron loading in the nanocages drastically impacts the performance of the memristive devices. The higher iron loading amount contributes to better memristive performance due to higher electrochemical activity of the ferric complex core.

Researchers demonstrate a strategy for the fabrication of memristive nanodevices with stable and tunable performance by assembling ferritin monolayer inside a on-wire lithography-generated 12 nm gap. This work work uses the unique high iron loading capacity of Archaeoglobus fulgidus ferritin. The iron loading in the nanocages drastically impacts the performance of the memristive devices. The higher iron loading amount contributes to better memristive performance due to higher electrochemical activity of the ferric complex core.

Dec 16th, 2013

Most of the accomplishments in building carbon nanotube circuits have come at the single-nanotube level. Researchers have been struggling with two major obstacles in building CNT-based circuits: the presence of metallic CNTs and a 'perfect' alignment of nanotubes. In new work, researchers have now demonstrated the ability to fabricate, in a scalable manner, larger-scale CNFET circuits at highly scaled technology nodes. The channel lengths are ranging from 90 nm to sub-20 nm.

Most of the accomplishments in building carbon nanotube circuits have come at the single-nanotube level. Researchers have been struggling with two major obstacles in building CNT-based circuits: the presence of metallic CNTs and a 'perfect' alignment of nanotubes. In new work, researchers have now demonstrated the ability to fabricate, in a scalable manner, larger-scale CNFET circuits at highly scaled technology nodes. The channel lengths are ranging from 90 nm to sub-20 nm.

Subscribe to our Nanotechnology Spotlight feed

Subscribe to our Nanotechnology Spotlight feed