Showing Spotlights 65 - 72 of 77 in category All (newest first):

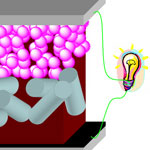

As the fields of bionanotechnologies develop, it will become possible one day to use biological nanodevices such as nanorobots for in situ and real-time in vivo diagnosis and therapeutic intervention of specific targets. A prerequisite for designing and constructing wireless biological nanorobots is the availability of an electrical source which can be made continuously available in the operational biological environment (i.e. the human body). Several possible sources - temperature displacement, kinetic energy derived from blood flow, and chemical energy released from biological motors inside the body - have been designed to provide the electrical sources that can reliably operate in body. Researchers now report the construction of a 980-nm laser-driven photovoltaic cell that can provide a sufficient power output even when covered by thick biological tissue layers.

As the fields of bionanotechnologies develop, it will become possible one day to use biological nanodevices such as nanorobots for in situ and real-time in vivo diagnosis and therapeutic intervention of specific targets. A prerequisite for designing and constructing wireless biological nanorobots is the availability of an electrical source which can be made continuously available in the operational biological environment (i.e. the human body). Several possible sources - temperature displacement, kinetic energy derived from blood flow, and chemical energy released from biological motors inside the body - have been designed to provide the electrical sources that can reliably operate in body. Researchers now report the construction of a 980-nm laser-driven photovoltaic cell that can provide a sufficient power output even when covered by thick biological tissue layers.

Dec 11th, 2009

A very ambitious idea that has been kicked around for the past couple of years has gained a lot of momentum over the past few months. The vision that, if realized, would be a true energy revolution, is called Desertec and would amount to the biggest solar energy project of all times. The project, if realized, will cost 400-500 billion euros ($550-700 bn) and deliver its first energy in about 10 years. The basic idea is to install a huge network of concentrating solar-thermal power plants in the Sahara desert and build a network of High-Voltage Direct Current transmission lines to carry the electricity to Europe. The Desertec concept describes the perspective of a sustainable supply of electricity for Europe, the Middle East and North Africa up to the year 2050. By then, it could satisfy as much as 15 percent of the European Union's power needs. It shows that a transition to competitive, secure and compatible supply is possible using renewable energy sources and efficiency gains, and fossil fuels as backup for balancing power. Also, the technology exists today - it's the scale of the vision that's revolutionary.

A very ambitious idea that has been kicked around for the past couple of years has gained a lot of momentum over the past few months. The vision that, if realized, would be a true energy revolution, is called Desertec and would amount to the biggest solar energy project of all times. The project, if realized, will cost 400-500 billion euros ($550-700 bn) and deliver its first energy in about 10 years. The basic idea is to install a huge network of concentrating solar-thermal power plants in the Sahara desert and build a network of High-Voltage Direct Current transmission lines to carry the electricity to Europe. The Desertec concept describes the perspective of a sustainable supply of electricity for Europe, the Middle East and North Africa up to the year 2050. By then, it could satisfy as much as 15 percent of the European Union's power needs. It shows that a transition to competitive, secure and compatible supply is possible using renewable energy sources and efficiency gains, and fossil fuels as backup for balancing power. Also, the technology exists today - it's the scale of the vision that's revolutionary.

Jul 13th, 2009

Increasing the efficiencies of polymer-based solar cells while at the same time keeping production complexity and cost low will require the preparation of new classes of polymers that can be prepared with a minimum of synthetic steps. Combining strong electron acceptors such as fullerenes (C60) with commodity polymers to make electronically active polymers promises to be one possible route. So far, though, the photovoltaic efficiencies of polymer/C60 blends are generally not as good as those for photovoltaic devices made from the currently used main classes of polymers, P3HT and PCBM. Researchers in France came up with a way to very simply prepare polymers from fullerenes without having to strongly change the aromaticity of the C60 sphere. This means that many of the original properties of C60 may be found to be retained even when combined with the beneficial properties of polymers.

Increasing the efficiencies of polymer-based solar cells while at the same time keeping production complexity and cost low will require the preparation of new classes of polymers that can be prepared with a minimum of synthetic steps. Combining strong electron acceptors such as fullerenes (C60) with commodity polymers to make electronically active polymers promises to be one possible route. So far, though, the photovoltaic efficiencies of polymer/C60 blends are generally not as good as those for photovoltaic devices made from the currently used main classes of polymers, P3HT and PCBM. Researchers in France came up with a way to very simply prepare polymers from fullerenes without having to strongly change the aromaticity of the C60 sphere. This means that many of the original properties of C60 may be found to be retained even when combined with the beneficial properties of polymers.

May 29th, 2009

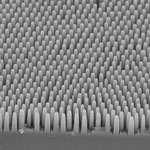

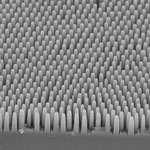

Antireflection coatings have become one of the key issues for mass production of silicon solar cells. Silicon solar cells are the most common solar cells on the market today. They are constructed with layers of n-type silicon having many electrons and p-type silicon having many electron holes. When hit by sunlight, an equal number of electrons and electron holes are generated at the interface between the two silicon layers and, as the electrons migrate from the n-type silicon to the p-type silicon, an electric flow is generated. One of the problems with silicon solar cells is the high refractive index of silicon, which causes more than 30% of incident light to be reflected back from the surface of the silicon crystals. Solar cell manufacturers have therefore developed various kinds of antireflection coatings (ARCs) to reduce the unwanted reflective losses. Currently, quarter-wavelength silicon nitride thin films deposited by plasma-enhanced chemical vapor deposition (PECVD) are the industrial standard for ARCs on crystalline silicon substrates. Unfortunately, current top-down lithographic techniques for creating subwavelength silicon gratings, such as electron-beam lithography, nanoimprint lithography, and interference lithography, require sophisticated equipment and are expensive to implement, thus contributing to the still high costs of this type of solar cells. Borrowing from Mother Nature's millions of years old design book, researchers have now come up with a nanotechnology antireflection coating inspired by the eyes of moths.

Antireflection coatings have become one of the key issues for mass production of silicon solar cells. Silicon solar cells are the most common solar cells on the market today. They are constructed with layers of n-type silicon having many electrons and p-type silicon having many electron holes. When hit by sunlight, an equal number of electrons and electron holes are generated at the interface between the two silicon layers and, as the electrons migrate from the n-type silicon to the p-type silicon, an electric flow is generated. One of the problems with silicon solar cells is the high refractive index of silicon, which causes more than 30% of incident light to be reflected back from the surface of the silicon crystals. Solar cell manufacturers have therefore developed various kinds of antireflection coatings (ARCs) to reduce the unwanted reflective losses. Currently, quarter-wavelength silicon nitride thin films deposited by plasma-enhanced chemical vapor deposition (PECVD) are the industrial standard for ARCs on crystalline silicon substrates. Unfortunately, current top-down lithographic techniques for creating subwavelength silicon gratings, such as electron-beam lithography, nanoimprint lithography, and interference lithography, require sophisticated equipment and are expensive to implement, thus contributing to the still high costs of this type of solar cells. Borrowing from Mother Nature's millions of years old design book, researchers have now come up with a nanotechnology antireflection coating inspired by the eyes of moths.

Oct 28th, 2008

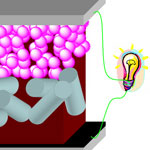

Harnessing the power of the sun to replace the use of fossil fuels holds tremendous promise. One way to do this is through the use of solar, or photovoltaic, cells. Large-scale installation already show the technical feasibility of this technology although the major problem of photovoltaic solar energy - its relative inefficiency - still needs to be overcome to make the cost of electricity produced by solar cells equal or less than electricity produced by nuclear or fossil fuels. Until now, solar cells that convert sunlight to electric power have been dominated by solid state junction devices, often made of silicon wafers. Efforts are being made in laboratories worldwide to design ordered assemblies of semiconductor nanostructures, metal nanoparticles and carbon nanotubes for constructing next generation solar energy conversion devices. Quantum dots have been identified as important light harvesting material for building highly efficient solar cells. Quantum dots are nanoscale semiconductor structures which, when exposed to light at certain wavelengths, can generate free electrons and create an electrical current. Quantum dot technology represents an exciting field of research in solar energy yet the actual research results to use them in solar cells are relatively limited. By combining spectroscopic and photoelectrochemical techniques, researchers now have demonstrated size-dependent charge injection from different-sized cadmium selenide (CdSe) quantum dots into titanium dioxide nanoparticles and nanotubes, showing a way to maximize the light absorption of quantum dot-based solar cells. Termed 'rainbow solar cells', these next-generation solar cells consist of different size quantum dots assembled in an orderly fashion. Just as a rainbow displays multiple colors of the visible light spectrum, the 'rainbow solar cell' has the potential to simultaneously absorb multiple wavelengths of light and convert it to electricity in a very efficient manner.

Harnessing the power of the sun to replace the use of fossil fuels holds tremendous promise. One way to do this is through the use of solar, or photovoltaic, cells. Large-scale installation already show the technical feasibility of this technology although the major problem of photovoltaic solar energy - its relative inefficiency - still needs to be overcome to make the cost of electricity produced by solar cells equal or less than electricity produced by nuclear or fossil fuels. Until now, solar cells that convert sunlight to electric power have been dominated by solid state junction devices, often made of silicon wafers. Efforts are being made in laboratories worldwide to design ordered assemblies of semiconductor nanostructures, metal nanoparticles and carbon nanotubes for constructing next generation solar energy conversion devices. Quantum dots have been identified as important light harvesting material for building highly efficient solar cells. Quantum dots are nanoscale semiconductor structures which, when exposed to light at certain wavelengths, can generate free electrons and create an electrical current. Quantum dot technology represents an exciting field of research in solar energy yet the actual research results to use them in solar cells are relatively limited. By combining spectroscopic and photoelectrochemical techniques, researchers now have demonstrated size-dependent charge injection from different-sized cadmium selenide (CdSe) quantum dots into titanium dioxide nanoparticles and nanotubes, showing a way to maximize the light absorption of quantum dot-based solar cells. Termed 'rainbow solar cells', these next-generation solar cells consist of different size quantum dots assembled in an orderly fashion. Just as a rainbow displays multiple colors of the visible light spectrum, the 'rainbow solar cell' has the potential to simultaneously absorb multiple wavelengths of light and convert it to electricity in a very efficient manner.

Mar 6th, 2008

Nanotechnology is already part of the process through which silicon-based photovoltaic solar cells - which make up some 95 percent of the solar cell market today - produce electricity. Nanotechnology is also the focus of research and development of a new generation of solar power technology that includes organic and inorganic solar cells derived from nanocrystals that can convert sunlight into electricity at a fraction of the cost of silicon solar cells. Silicon-based solar cells are made from a refined, highly purified silicon crystal, similar to those used in the manufacture of integrated circuits and computer chips. The high cost of these silicon solar cells and their complex production process has generated interest in developing alternative photovoltaic technologies. Compared to silicon-based devices, polymer solar cells are lightweight (which is important for small autonomous sensors), disposable, inexpensive to fabricate, flexible, designable on the molecular level, and have little potential for negative environmental impact. These solar nanocells are so small and pliable that they can be painted onto physical structures so that the windows and walls of a building may one day soon be able to generate electricity. The big question today is to what degree polymer solar cells will be able to commercially compete with silicon solar cells. There are two major issues that need to be solved: 1) The present efficiency of organic solar cells lies at only around 6 percent, compared to up to 30 percent for the most efficient silicon cells. 2) Polymer solar cells suffer from huge degradation effects: the efficiency is decreased over time due to environmental effects such as water, oxygen or UV rays.

Nanotechnology is already part of the process through which silicon-based photovoltaic solar cells - which make up some 95 percent of the solar cell market today - produce electricity. Nanotechnology is also the focus of research and development of a new generation of solar power technology that includes organic and inorganic solar cells derived from nanocrystals that can convert sunlight into electricity at a fraction of the cost of silicon solar cells. Silicon-based solar cells are made from a refined, highly purified silicon crystal, similar to those used in the manufacture of integrated circuits and computer chips. The high cost of these silicon solar cells and their complex production process has generated interest in developing alternative photovoltaic technologies. Compared to silicon-based devices, polymer solar cells are lightweight (which is important for small autonomous sensors), disposable, inexpensive to fabricate, flexible, designable on the molecular level, and have little potential for negative environmental impact. These solar nanocells are so small and pliable that they can be painted onto physical structures so that the windows and walls of a building may one day soon be able to generate electricity. The big question today is to what degree polymer solar cells will be able to commercially compete with silicon solar cells. There are two major issues that need to be solved: 1) The present efficiency of organic solar cells lies at only around 6 percent, compared to up to 30 percent for the most efficient silicon cells. 2) Polymer solar cells suffer from huge degradation effects: the efficiency is decreased over time due to environmental effects such as water, oxygen or UV rays.

Mar 4th, 2008

Titanium oxide - due to its versatile optical, electrical and photochemical properties, its relative abundance and low cost, and its non-toxicity - is an important ceramic material with numerous applications as pigments; powders for catalytic or photocatalytic applications; colloids and thin films for photovoltaic, electrochromic, photochromic, electroluminescence devices and sensors; components for antireflecting coatings; or porous membranes for ultrafiltration. Nanocrystalline titania has become a prominent material for dye-sensitized solar cells (DSSCs, also known as 'Grätzel cells' after their inventor), which are photoelectrochemical cells that use photo-sensitization of wide-band-gap mesoporous oxide semiconductors. One major problem with the use of titania in solar cells is that its bandgap does not match that of visible light and titania therefore can only absorb 3-4% of the energy from sunlight. Grätzel cells decrease the bandgap of titania by using dye-absorbed TiO2 nanocrystals as one of the electrodes, resulting in a higher solar energy conversion of 10% or more. Other methods use doping and indeed the application of nitrogen-doped titania as photocatalyst has received increasing attention over the last years because N-doping is found to be particularly effective in decreasing the bandgap of anatase (many of the properties of titania depend on the structure of the TiO2 phase - mainly anatase, brookite and rutile). In order for photocatalysis-based applications to become commercially viable, it will be critical to design low-cost, reproducible, synthetic methods that yield controlled, reproducible, and easy-to-handle nanomaterials processed as coatings with high surface area and high porosity. Researchers in France and Spain now describe for the first time nanostructured coatings that fulfill all these requirements.

Titanium oxide - due to its versatile optical, electrical and photochemical properties, its relative abundance and low cost, and its non-toxicity - is an important ceramic material with numerous applications as pigments; powders for catalytic or photocatalytic applications; colloids and thin films for photovoltaic, electrochromic, photochromic, electroluminescence devices and sensors; components for antireflecting coatings; or porous membranes for ultrafiltration. Nanocrystalline titania has become a prominent material for dye-sensitized solar cells (DSSCs, also known as 'Grätzel cells' after their inventor), which are photoelectrochemical cells that use photo-sensitization of wide-band-gap mesoporous oxide semiconductors. One major problem with the use of titania in solar cells is that its bandgap does not match that of visible light and titania therefore can only absorb 3-4% of the energy from sunlight. Grätzel cells decrease the bandgap of titania by using dye-absorbed TiO2 nanocrystals as one of the electrodes, resulting in a higher solar energy conversion of 10% or more. Other methods use doping and indeed the application of nitrogen-doped titania as photocatalyst has received increasing attention over the last years because N-doping is found to be particularly effective in decreasing the bandgap of anatase (many of the properties of titania depend on the structure of the TiO2 phase - mainly anatase, brookite and rutile). In order for photocatalysis-based applications to become commercially viable, it will be critical to design low-cost, reproducible, synthetic methods that yield controlled, reproducible, and easy-to-handle nanomaterials processed as coatings with high surface area and high porosity. Researchers in France and Spain now describe for the first time nanostructured coatings that fulfill all these requirements.

Nov 8th, 2007

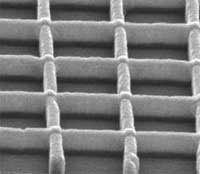

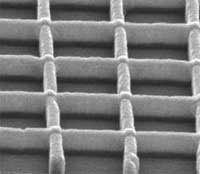

OLEDs - organic light-emitting diodes - are full of promise for a range of practical applications not too far into the future. Today, OLEDs are used in small electronic device displays in mobile phones, MP3 players, digital cameras, etc. With more efficient and cheaper OLED technologies we soon will see ultraflat, very bright and power-saving OLED televisions, windows that could be used as light source at night, and large-scale organic solar cells. In contrast to regular LEDs, the emissive electroluminescent layer of an OLED consists of a thin-film of organic compounds. What makes OLEDs so attractive is that they do not require a backlight to function. Thus they draw far less power and, when powered from a battery, can operate longer on the same charge. OLED devices can be made thinner and lighter than comparable LED devices. Last but not least, OLEDs can be printed onto almost any substrate with inkjet printer technology, making new applications like displays embedded in clothes or roll-up displays possible. Unfortunately there are also drawbacks to this technology. Apart from its currently high manufacturing cost, the major problem is device degradation and the limited lifetime of organic materials. In particular, the most commonly used material for the anode, ITO (indium tin oxide), is a less than optimal material for future high-performance OLEDs. New research indicates that nanoimprinted semitransparent metal electrodes, replacing ITO electrodes, are an attractive and potentially practical solution for OLEDs and other organic devices.

OLEDs - organic light-emitting diodes - are full of promise for a range of practical applications not too far into the future. Today, OLEDs are used in small electronic device displays in mobile phones, MP3 players, digital cameras, etc. With more efficient and cheaper OLED technologies we soon will see ultraflat, very bright and power-saving OLED televisions, windows that could be used as light source at night, and large-scale organic solar cells. In contrast to regular LEDs, the emissive electroluminescent layer of an OLED consists of a thin-film of organic compounds. What makes OLEDs so attractive is that they do not require a backlight to function. Thus they draw far less power and, when powered from a battery, can operate longer on the same charge. OLED devices can be made thinner and lighter than comparable LED devices. Last but not least, OLEDs can be printed onto almost any substrate with inkjet printer technology, making new applications like displays embedded in clothes or roll-up displays possible. Unfortunately there are also drawbacks to this technology. Apart from its currently high manufacturing cost, the major problem is device degradation and the limited lifetime of organic materials. In particular, the most commonly used material for the anode, ITO (indium tin oxide), is a less than optimal material for future high-performance OLEDs. New research indicates that nanoimprinted semitransparent metal electrodes, replacing ITO electrodes, are an attractive and potentially practical solution for OLEDs and other organic devices.

Jun 7th, 2007

As the fields of bionanotechnologies develop, it will become possible one day to use biological nanodevices such as nanorobots for in situ and real-time in vivo diagnosis and therapeutic intervention of specific targets. A prerequisite for designing and constructing wireless biological nanorobots is the availability of an electrical source which can be made continuously available in the operational biological environment (i.e. the human body). Several possible sources - temperature displacement, kinetic energy derived from blood flow, and chemical energy released from biological motors inside the body - have been designed to provide the electrical sources that can reliably operate in body. Researchers now report the construction of a 980-nm laser-driven photovoltaic cell that can provide a sufficient power output even when covered by thick biological tissue layers.

As the fields of bionanotechnologies develop, it will become possible one day to use biological nanodevices such as nanorobots for in situ and real-time in vivo diagnosis and therapeutic intervention of specific targets. A prerequisite for designing and constructing wireless biological nanorobots is the availability of an electrical source which can be made continuously available in the operational biological environment (i.e. the human body). Several possible sources - temperature displacement, kinetic energy derived from blood flow, and chemical energy released from biological motors inside the body - have been designed to provide the electrical sources that can reliably operate in body. Researchers now report the construction of a 980-nm laser-driven photovoltaic cell that can provide a sufficient power output even when covered by thick biological tissue layers.

Subscribe to our Nanotechnology Spotlight feed

Subscribe to our Nanotechnology Spotlight feed