Showing Spotlights 49 - 56 of 77 in category All (newest first):

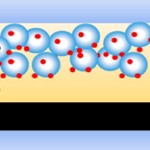

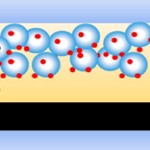

Dye-sensitized solar cells (DSSCs) are among the most promising photovoltaic devices for low-cost light-to-energy conversion with relatively high efficiency. While the DSSC is a fairly mature design, researchers are still trying to improve its efficiency with various techniques. To date, the most commonly used counter electrode in DSSC is fluorine doped tin oxide glass coated with a thin layer of platinum. However, as a noble metal, the low abundance and high cost hinder platinum from being used for large-scale manufacturing. In the quest to seek alternative counter electrode materials for expensive and scarce platinum, a group of scientists has now explored the use of abundant ternary or quaternary materials as potential substitutes for platinum.

Dye-sensitized solar cells (DSSCs) are among the most promising photovoltaic devices for low-cost light-to-energy conversion with relatively high efficiency. While the DSSC is a fairly mature design, researchers are still trying to improve its efficiency with various techniques. To date, the most commonly used counter electrode in DSSC is fluorine doped tin oxide glass coated with a thin layer of platinum. However, as a noble metal, the low abundance and high cost hinder platinum from being used for large-scale manufacturing. In the quest to seek alternative counter electrode materials for expensive and scarce platinum, a group of scientists has now explored the use of abundant ternary or quaternary materials as potential substitutes for platinum.

Sep 13th, 2011

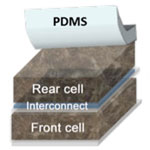

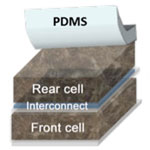

Apart from making graphene, graphene oxide itself itself is a fascinating material that has many intriguing properties. Researchers have now developed a graphene-based conductive glue that can function as a metal-free solder for creating mechanical and electrical connections in organic optoelectronic devices. As a proof-of-concept, they fabricated polymer tandem solar cells - multi-junction photovoltaic devices, in which two sub-cells are stacked to achieve higher overall solar absorption - by a direct 'gluing' process. The water-based sticky interconnect and the associated adhesive lamination process could transform the serial layer-by-layer fabrication of tandem devices into a parallel mode, in which the subcells can be independently fabricated and adjusted to balance their photocurrents for achieving high efficiency.

Apart from making graphene, graphene oxide itself itself is a fascinating material that has many intriguing properties. Researchers have now developed a graphene-based conductive glue that can function as a metal-free solder for creating mechanical and electrical connections in organic optoelectronic devices. As a proof-of-concept, they fabricated polymer tandem solar cells - multi-junction photovoltaic devices, in which two sub-cells are stacked to achieve higher overall solar absorption - by a direct 'gluing' process. The water-based sticky interconnect and the associated adhesive lamination process could transform the serial layer-by-layer fabrication of tandem devices into a parallel mode, in which the subcells can be independently fabricated and adjusted to balance their photocurrents for achieving high efficiency.

Jun 10th, 2011

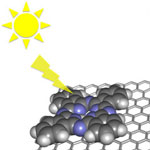

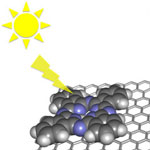

The extremely high electron mobility of graphene - under ideal conditions electrons move through it with roughly 100 times the mobility they have in silicon - combined with its superior strength and the fact that it is nearly transparent (2.3 % of light is absorbed; 97.7 % transmitted), make it an ideal candidate for photovoltaic applications. Recent research suggests, though, that doping is a necessity to harvest the full potential of graphene. The challenge then for researchers is to find suitable fabrication techniques for high-quality graphene flakes that exhibit high charge mobilities. Researchers now present a chemical approach towards non-covalently functionalized graphene, which is generated from vastly available and low-priced natural graphite.

The extremely high electron mobility of graphene - under ideal conditions electrons move through it with roughly 100 times the mobility they have in silicon - combined with its superior strength and the fact that it is nearly transparent (2.3 % of light is absorbed; 97.7 % transmitted), make it an ideal candidate for photovoltaic applications. Recent research suggests, though, that doping is a necessity to harvest the full potential of graphene. The challenge then for researchers is to find suitable fabrication techniques for high-quality graphene flakes that exhibit high charge mobilities. Researchers now present a chemical approach towards non-covalently functionalized graphene, which is generated from vastly available and low-priced natural graphite.

Apr 19th, 2011

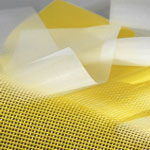

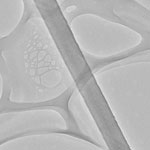

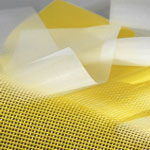

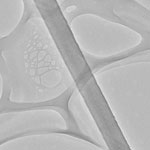

In order to find replacement materials for ITO, scientists have been working with carbon nanotubes, graphene, and other nanoscale materials such as nanowires. While many of these approaches work fine in the lab, upscaleability usually has been an issue. Researchers at Empa, the Swiss Federal Laboratories for Material Science and Technology, have now demonstrated another solution: they presented a transparent and flexible electrode based on a precision fabric with metal and polymer fibers woven into a mesh. The team demonstrated organic solar cells fabricated on their flexible precision fabrics as well as on conventional glass/ITO substrates and found very similar performance characteristics.

In order to find replacement materials for ITO, scientists have been working with carbon nanotubes, graphene, and other nanoscale materials such as nanowires. While many of these approaches work fine in the lab, upscaleability usually has been an issue. Researchers at Empa, the Swiss Federal Laboratories for Material Science and Technology, have now demonstrated another solution: they presented a transparent and flexible electrode based on a precision fabric with metal and polymer fibers woven into a mesh. The team demonstrated organic solar cells fabricated on their flexible precision fabrics as well as on conventional glass/ITO substrates and found very similar performance characteristics.

Apr 4th, 2011

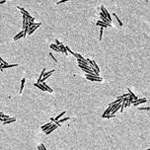

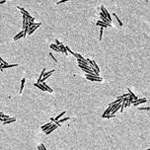

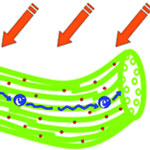

The power conversion efficiency of solar cells made of conjugated polymer/nanorod nanocomposites can be maximized when the nanocomposites are aligned perpendicularly between two electrodes for effective exciton dissociation and transport. To realize this, external fields can be applied to induce the self-assembly/alignment. The challenge is how to assemble them over a large scale - current self-assembly studies of cadmium selenide nanorods in literature are limited to only a micrometer scale. New design approaches are therefore needed to solve this problem. Due to their intrinsic structural anisotropy, nanorods possess many unique properties that make them potentially better nanocrystals than quantum dots for photovoltaics and biomedical applications.

The power conversion efficiency of solar cells made of conjugated polymer/nanorod nanocomposites can be maximized when the nanocomposites are aligned perpendicularly between two electrodes for effective exciton dissociation and transport. To realize this, external fields can be applied to induce the self-assembly/alignment. The challenge is how to assemble them over a large scale - current self-assembly studies of cadmium selenide nanorods in literature are limited to only a micrometer scale. New design approaches are therefore needed to solve this problem. Due to their intrinsic structural anisotropy, nanorods possess many unique properties that make them potentially better nanocrystals than quantum dots for photovoltaics and biomedical applications.

Mar 29th, 2011

In a standard dye sensitized solar cell, an organic molecule adsorbed on the surface of a porous electrode absorbs light and then initiates the charge separation process eventually leading to generation of photocurrent. While the dye appears to have "sensitized" the large bandgap material, it never actually does, because only the dye molecules absorb the light and generate the carriers, the large bandgap material primarily serves the function of a conducting channel to take the electrons out. While wide bandgap materials alone can not absorb the sun light efficiently, it has been predicted that if two large bandgap materials with type-II band alignment form coaxial nanowires, the effective indirect bandgap could be substantially smaller than either of the individual materials. After a few years effort, one research team has now demonstrated a real functional device that exhibits the key feature of the idea: the use of two large bandgap materials to make a solar cell behaving like a small bandgap material.

In a standard dye sensitized solar cell, an organic molecule adsorbed on the surface of a porous electrode absorbs light and then initiates the charge separation process eventually leading to generation of photocurrent. While the dye appears to have "sensitized" the large bandgap material, it never actually does, because only the dye molecules absorb the light and generate the carriers, the large bandgap material primarily serves the function of a conducting channel to take the electrons out. While wide bandgap materials alone can not absorb the sun light efficiently, it has been predicted that if two large bandgap materials with type-II band alignment form coaxial nanowires, the effective indirect bandgap could be substantially smaller than either of the individual materials. After a few years effort, one research team has now demonstrated a real functional device that exhibits the key feature of the idea: the use of two large bandgap materials to make a solar cell behaving like a small bandgap material.

Mar 18th, 2011

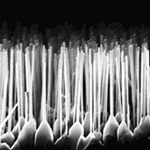

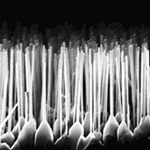

Nanowires - particularly those of silicon - promise great potentials for high-efficiency, low-cost solar energy conversion. This promise has not yet been met by experimental evidence, raising fundamental questions whether silicon nanowires are intrinsically disadvantaged and whether the photovoltaic research community should continue working on this material. Despite intense efforts, the performance of silicon nanowire-based solar cells remains significantly lower than what has been achieved for bulk silicon or micrometer-scale wires. The gap between the predicted performance and the inability to deliver raises an important question with regard to the origin of this problem. New research shows that the poor performance is not a result of the nanowire morphology, but is intrinsic to the growth chemistry.

Nanowires - particularly those of silicon - promise great potentials for high-efficiency, low-cost solar energy conversion. This promise has not yet been met by experimental evidence, raising fundamental questions whether silicon nanowires are intrinsically disadvantaged and whether the photovoltaic research community should continue working on this material. Despite intense efforts, the performance of silicon nanowire-based solar cells remains significantly lower than what has been achieved for bulk silicon or micrometer-scale wires. The gap between the predicted performance and the inability to deliver raises an important question with regard to the origin of this problem. New research shows that the poor performance is not a result of the nanowire morphology, but is intrinsic to the growth chemistry.

Mar 9th, 2011

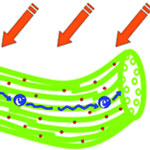

There is an increasing interest in flexible solar cells and researchers have been investigating weavable fiber solar cells based on metal wires, glass fibers, or polymer fibers. Unfortunately, the low efficiencies of these fiber-based solar cells greatly limit their promising applications. In order to improve these efficiencies, scientists are exploring various nanomaterials to improve charge separation and transport in these fiber-based photovoltaic devices. One recent promising result has been demonstrated by a research team in China who have developed a novel solar cell from flexible, light-weight, ultrastrong, and semiconductive carbon nanotube fiber. The high alignment of building nanotubes in the fiber allows charges to separate and transport along the fibers efficiently, which provides a fiber solar cell with high performance.

There is an increasing interest in flexible solar cells and researchers have been investigating weavable fiber solar cells based on metal wires, glass fibers, or polymer fibers. Unfortunately, the low efficiencies of these fiber-based solar cells greatly limit their promising applications. In order to improve these efficiencies, scientists are exploring various nanomaterials to improve charge separation and transport in these fiber-based photovoltaic devices. One recent promising result has been demonstrated by a research team in China who have developed a novel solar cell from flexible, light-weight, ultrastrong, and semiconductive carbon nanotube fiber. The high alignment of building nanotubes in the fiber allows charges to separate and transport along the fibers efficiently, which provides a fiber solar cell with high performance.

Feb 1st, 2011

Dye-sensitized solar cells (DSSCs) are among the most promising photovoltaic devices for low-cost light-to-energy conversion with relatively high efficiency. While the DSSC is a fairly mature design, researchers are still trying to improve its efficiency with various techniques. To date, the most commonly used counter electrode in DSSC is fluorine doped tin oxide glass coated with a thin layer of platinum. However, as a noble metal, the low abundance and high cost hinder platinum from being used for large-scale manufacturing. In the quest to seek alternative counter electrode materials for expensive and scarce platinum, a group of scientists has now explored the use of abundant ternary or quaternary materials as potential substitutes for platinum.

Dye-sensitized solar cells (DSSCs) are among the most promising photovoltaic devices for low-cost light-to-energy conversion with relatively high efficiency. While the DSSC is a fairly mature design, researchers are still trying to improve its efficiency with various techniques. To date, the most commonly used counter electrode in DSSC is fluorine doped tin oxide glass coated with a thin layer of platinum. However, as a noble metal, the low abundance and high cost hinder platinum from being used for large-scale manufacturing. In the quest to seek alternative counter electrode materials for expensive and scarce platinum, a group of scientists has now explored the use of abundant ternary or quaternary materials as potential substitutes for platinum.

Subscribe to our Nanotechnology Spotlight feed

Subscribe to our Nanotechnology Spotlight feed