Showing Spotlights 2593 - 2600 of 2851 in category All (newest first):

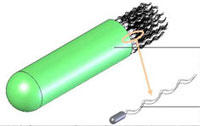

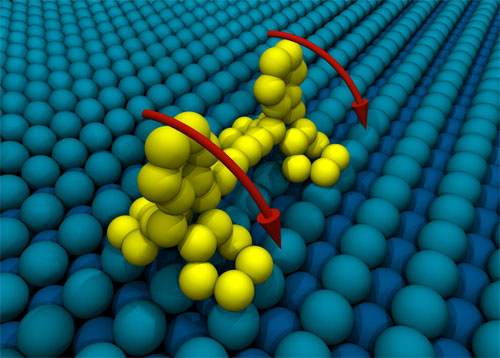

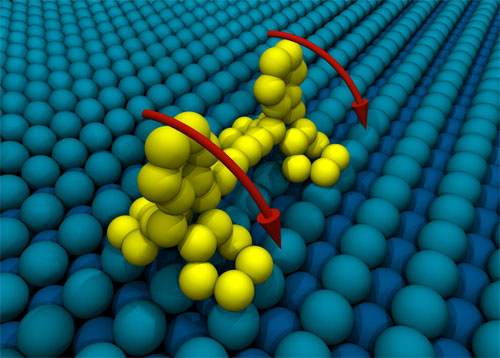

The invention of the wheel was one of the most significant events in human history. It has been at the origin of major scientific and technological developments: from the creation of astronomical clocks or calculating machines to motor-drawn vehicles and other motor cars. At the molecular scale, the smallest at which a wheel can be created, it represents a major challenge for chemists and physicists. For years, scientists have been working on the design of molecular machines equipped with wheels. After observing the random rotation of a flat molecular wheel in 1998, designing and synthesizing a mono-molecular wheelbarrow in 2003 and then synthesizing a molecular motor in 2005, a European group of researchers managed to operate the first molecular rack with a pinion of 1.2 nm in diameter. They controlled the rotation of a 0.7 nm diameter wheel attached to a 0.6 nm-long axle in a molecule. This molecular 'wheel' could revolutionize machinery built at the nanoscale. Nanowheel rotation has been claimed before, but never shown directly.

The invention of the wheel was one of the most significant events in human history. It has been at the origin of major scientific and technological developments: from the creation of astronomical clocks or calculating machines to motor-drawn vehicles and other motor cars. At the molecular scale, the smallest at which a wheel can be created, it represents a major challenge for chemists and physicists. For years, scientists have been working on the design of molecular machines equipped with wheels. After observing the random rotation of a flat molecular wheel in 1998, designing and synthesizing a mono-molecular wheelbarrow in 2003 and then synthesizing a molecular motor in 2005, a European group of researchers managed to operate the first molecular rack with a pinion of 1.2 nm in diameter. They controlled the rotation of a 0.7 nm diameter wheel attached to a 0.6 nm-long axle in a molecule. This molecular 'wheel' could revolutionize machinery built at the nanoscale. Nanowheel rotation has been claimed before, but never shown directly.

Feb 26th, 2007

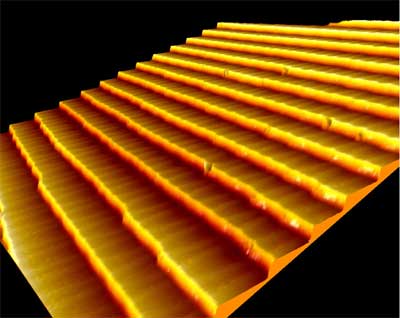

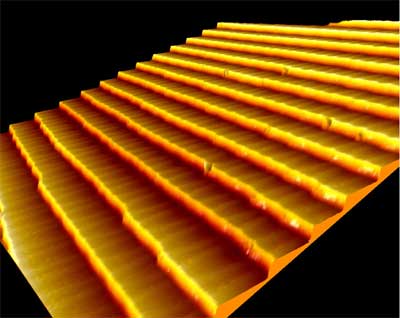

Strong and highly directional hydrogen-bonding networks are of fundamental importance in nature. Their efficiency in assisting electron-transfer processes makes them increasingly appealing for technological application inspired by biomimetic principles, i.e. the application of methods and systems found in nature to the study and design of engineering systems and modern technology. Attempting to move from microelectronics to nanoelectronics, engineers are faced with the growing difficulty of manufacturing ever tinier devices with top-down engineering approaches. They are therefore looking at possible ways for bottom-up engineering approaches with the goal of achieving the holy grail of nanotechnology - molecular self-assembly. For some time now researchers have been able to design molecules in such a way that they attach themselves to each other in alternating order, and under certain circumstances - for example on surfaces - create chains. Unfortunately the chains are not very long, because all surfaces, even extremely smooth ones, show unevenness at the atomic level. Step edges, although only a few atomic layers high, represent insurmountable hurdles to the self-assembly process, and since they are distributed randomly over the surface, the molecules form themselves into very irregular patterns. Overcoming this problem, researchers were recently able to formulate two organic molecules in such a way that they organized themselves spontaneously into long parallel chains (nanowires) on a specially prepared gold surface. Selective self-assembly on surfaces and the fundamental processes which control this phenomenon are, however, not only critical in the area of molecular electronics but also in heterogeneous catalysis - a process used in automotive catalytic converters - and in sensor technologies.

Strong and highly directional hydrogen-bonding networks are of fundamental importance in nature. Their efficiency in assisting electron-transfer processes makes them increasingly appealing for technological application inspired by biomimetic principles, i.e. the application of methods and systems found in nature to the study and design of engineering systems and modern technology. Attempting to move from microelectronics to nanoelectronics, engineers are faced with the growing difficulty of manufacturing ever tinier devices with top-down engineering approaches. They are therefore looking at possible ways for bottom-up engineering approaches with the goal of achieving the holy grail of nanotechnology - molecular self-assembly. For some time now researchers have been able to design molecules in such a way that they attach themselves to each other in alternating order, and under certain circumstances - for example on surfaces - create chains. Unfortunately the chains are not very long, because all surfaces, even extremely smooth ones, show unevenness at the atomic level. Step edges, although only a few atomic layers high, represent insurmountable hurdles to the self-assembly process, and since they are distributed randomly over the surface, the molecules form themselves into very irregular patterns. Overcoming this problem, researchers were recently able to formulate two organic molecules in such a way that they organized themselves spontaneously into long parallel chains (nanowires) on a specially prepared gold surface. Selective self-assembly on surfaces and the fundamental processes which control this phenomenon are, however, not only critical in the area of molecular electronics but also in heterogeneous catalysis - a process used in automotive catalytic converters - and in sensor technologies.

Feb 23rd, 2007

With an increased focus on alternative sources of cheap, abundant, clean energy, solar cells are receiving lots of attention. Harnessing the power of the sun to replace the use of fossil fuels holds tremendous promise. One way to do this is through the use of solar, or photovoltaic, cells. Until now, solar cells that convert sunlight to electric power have been dominated by solid state junction devices, often made of silicon wafers. Thanks to nanotechnology, this is now being challenged by the development of a new generation of solar cells based on thin film materials, nanocrystalline materials and conducting polymeric films. These offer the prospects of cheaper materials, higher efficiency and flexible features. This has opened up new opportunities in solar cell research and development and, consequently, there is considerable investor interest in solar nanotechnology startups. Both inventors and investors are betting that flexible sheets of solar cells used to harness the sun's strength will ultimately provide a cheap and efficient source of energy.

With an increased focus on alternative sources of cheap, abundant, clean energy, solar cells are receiving lots of attention. Harnessing the power of the sun to replace the use of fossil fuels holds tremendous promise. One way to do this is through the use of solar, or photovoltaic, cells. Until now, solar cells that convert sunlight to electric power have been dominated by solid state junction devices, often made of silicon wafers. Thanks to nanotechnology, this is now being challenged by the development of a new generation of solar cells based on thin film materials, nanocrystalline materials and conducting polymeric films. These offer the prospects of cheaper materials, higher efficiency and flexible features. This has opened up new opportunities in solar cell research and development and, consequently, there is considerable investor interest in solar nanotechnology startups. Both inventors and investors are betting that flexible sheets of solar cells used to harness the sun's strength will ultimately provide a cheap and efficient source of energy.

Feb 22nd, 2007

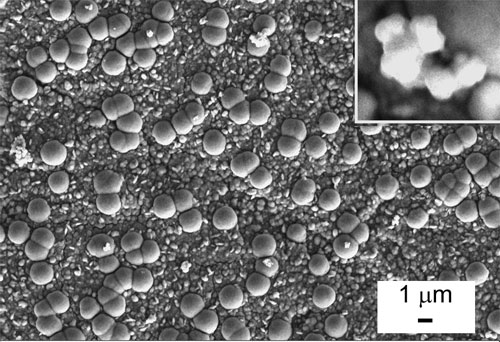

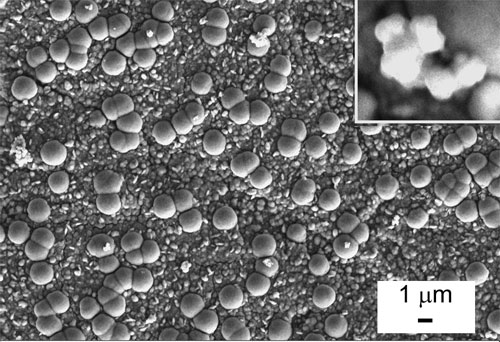

While many dynamic systems are lubricated by fluids of various kinds, modern technologies, like aerospace, clean room equipment, medical devices and machines, require the application of dry coatings which exhibit reduced friction and wear. Lubrication of dynamic surfaces by fluids adds complexity, weight and cost to the system, which imposes various constraints and limits the performance of these systems. Self-lubricating coatings, i.e. coatings which exhibit reduced wear and friction without resorting to tribological fluids, have been known for many years and are in use for a variety of applications. Numerous studies have shown that different nanoparticles, impregnated into metal, polymer, ceramic and other coatings, can provide these materials with enhanced tribological performance. Prominent among these additives are the fullerene-like (IF) nanoparticles of tungsten disulfide (WS2) and molybdenum disulfide (MoS2). New research shows that it is possible to obtain self-lubrication of hard (i.e. dry) coatings such as cobalt by impregnating fullerene-like nanoparticles of WS2 in such coatings. The coating serves as a reservoir of nanoparticles which are slowly released from the surface and provide easy shear and reduced oxidation of the coating or native metal surface, which is a common phenomenon in tribology (friction and wear) of metallic surfaces.

While many dynamic systems are lubricated by fluids of various kinds, modern technologies, like aerospace, clean room equipment, medical devices and machines, require the application of dry coatings which exhibit reduced friction and wear. Lubrication of dynamic surfaces by fluids adds complexity, weight and cost to the system, which imposes various constraints and limits the performance of these systems. Self-lubricating coatings, i.e. coatings which exhibit reduced wear and friction without resorting to tribological fluids, have been known for many years and are in use for a variety of applications. Numerous studies have shown that different nanoparticles, impregnated into metal, polymer, ceramic and other coatings, can provide these materials with enhanced tribological performance. Prominent among these additives are the fullerene-like (IF) nanoparticles of tungsten disulfide (WS2) and molybdenum disulfide (MoS2). New research shows that it is possible to obtain self-lubrication of hard (i.e. dry) coatings such as cobalt by impregnating fullerene-like nanoparticles of WS2 in such coatings. The coating serves as a reservoir of nanoparticles which are slowly released from the surface and provide easy shear and reduced oxidation of the coating or native metal surface, which is a common phenomenon in tribology (friction and wear) of metallic surfaces.

Feb 21st, 2007

As we reported today in our news coverage, the UK and the U.S. are to work together to develop a global science portal, making scientific information from many countries available via the internet. In contrast to the various national databases that already exist today, the new portal, to be known as "science.world", will build on the U.S. portal science.gov. The project has the goal of making the science offerings of all nations searchable in one global gateway. Given this comprehensive goal, and the rapidly gaining importance and wealth of nanotechnology related information, anything nanotech will have to be a significant part of this new library. One can't help but ask, though, if this effort by various nations' government agencies, led by the U.S. Department of Energy, is tax money well spent. Google, after all, is already developing such a service, called Google Scholar, and it beats all the existing government portals hands down.

As we reported today in our news coverage, the UK and the U.S. are to work together to develop a global science portal, making scientific information from many countries available via the internet. In contrast to the various national databases that already exist today, the new portal, to be known as "science.world", will build on the U.S. portal science.gov. The project has the goal of making the science offerings of all nations searchable in one global gateway. Given this comprehensive goal, and the rapidly gaining importance and wealth of nanotechnology related information, anything nanotech will have to be a significant part of this new library. One can't help but ask, though, if this effort by various nations' government agencies, led by the U.S. Department of Energy, is tax money well spent. Google, after all, is already developing such a service, called Google Scholar, and it beats all the existing government portals hands down.

Feb 20th, 2007

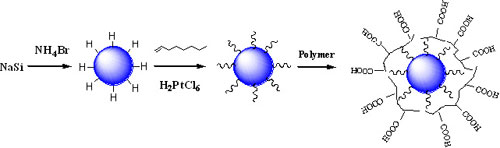

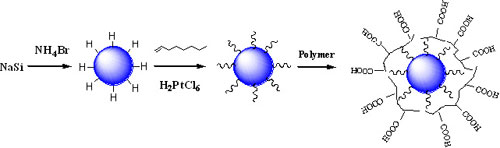

Current medical and biological fluorescent imaging is limited by the use of dye markers, which are not photostable. The dyes can break down under photoexcitation, room light or higher temperatures. The observation of strong visible emission in porous silicon therefore has triggered substantial interest in exploring the synthesis and characterization of silicon nanoparticles. Due to their biocompatibility, high photoluminescence quantum efficiency and stability against photobleaching, silicon nanoparticles are expected to be an ideal candidate for replacing fluorescent dyes in many biological assays and fluorescence imaging techniques. For instance, they have been proposed as better quantum dots for in vivo applications, potentially replacing quantum dots of highly toxic cadmium. Different synthetic and physical methods have been used to prepare silicon nanoparticles. However, the yields of nanoparticles from these methods are very low and an HF (hydrofluoric acid) etching process is often necessary to obtain photoluminescent, hydrogen-terminated silicon nanoparticles. Now, researchers have developed a new solution route for the production of macroscopic amounts of hydrogen terminated silicon nanoparticles without hazardous material handling. This synthesis route is simple and thus offers great opportunity for scaled-up preparation of semiconductor materials.

Current medical and biological fluorescent imaging is limited by the use of dye markers, which are not photostable. The dyes can break down under photoexcitation, room light or higher temperatures. The observation of strong visible emission in porous silicon therefore has triggered substantial interest in exploring the synthesis and characterization of silicon nanoparticles. Due to their biocompatibility, high photoluminescence quantum efficiency and stability against photobleaching, silicon nanoparticles are expected to be an ideal candidate for replacing fluorescent dyes in many biological assays and fluorescence imaging techniques. For instance, they have been proposed as better quantum dots for in vivo applications, potentially replacing quantum dots of highly toxic cadmium. Different synthetic and physical methods have been used to prepare silicon nanoparticles. However, the yields of nanoparticles from these methods are very low and an HF (hydrofluoric acid) etching process is often necessary to obtain photoluminescent, hydrogen-terminated silicon nanoparticles. Now, researchers have developed a new solution route for the production of macroscopic amounts of hydrogen terminated silicon nanoparticles without hazardous material handling. This synthesis route is simple and thus offers great opportunity for scaled-up preparation of semiconductor materials.

Feb 19th, 2007

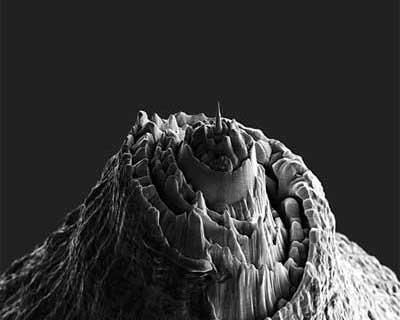

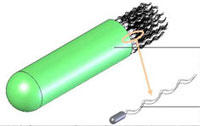

It's not quite like in Isaac Asimov's science fiction classic Fantastic Voyage, where five people travel in a submarine inside a person's blood stream, but scientists have talked for quite some time about micro and nanorobotic devices that can travel inside the human body and carry out a host of complex medical procedures such as monitoring, drug delivery and cell repair. Recent developments in micro- and nanoscale engineering have led to realization of various miniature mobile robots. It turns out that the most significant bottleneck for further miniaturization of mobile robots down to micrometer scale is the miniaturization of the on-board actuators and power sources required for mobility. Nature has already provided remarkable solutions to this problem by evolving chemically powered molecular motors. Such biomotors seem to be one of the most promising choices for on-board actuation. They are advantageous over man-made actuators because they are much smaller in size and are capable of producing more complicated motions. More importantly, they convert chemical energy to mechanical energy very efficiently. However, the major drawback of biomotors is that isolating and reconstituting them are complicated tasks with low yield and it is difficult to interface them with electronic circuitry. This has led scientists to successfully experiment with a new approach by using flagellar motors (the propulsion system of bacteria), still inside the intact cells, as actuators.

It's not quite like in Isaac Asimov's science fiction classic Fantastic Voyage, where five people travel in a submarine inside a person's blood stream, but scientists have talked for quite some time about micro and nanorobotic devices that can travel inside the human body and carry out a host of complex medical procedures such as monitoring, drug delivery and cell repair. Recent developments in micro- and nanoscale engineering have led to realization of various miniature mobile robots. It turns out that the most significant bottleneck for further miniaturization of mobile robots down to micrometer scale is the miniaturization of the on-board actuators and power sources required for mobility. Nature has already provided remarkable solutions to this problem by evolving chemically powered molecular motors. Such biomotors seem to be one of the most promising choices for on-board actuation. They are advantageous over man-made actuators because they are much smaller in size and are capable of producing more complicated motions. More importantly, they convert chemical energy to mechanical energy very efficiently. However, the major drawback of biomotors is that isolating and reconstituting them are complicated tasks with low yield and it is difficult to interface them with electronic circuitry. This has led scientists to successfully experiment with a new approach by using flagellar motors (the propulsion system of bacteria), still inside the intact cells, as actuators.

Feb 16th, 2007

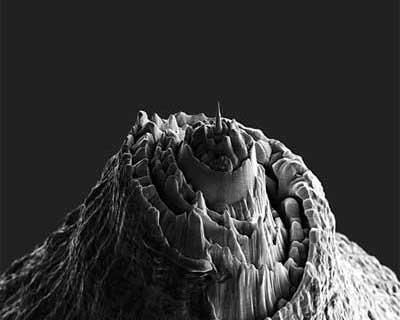

The nanoworld cannot be portrayed with a camera, nor can it be seen even with the most powerful optical microscope. Only special instruments have access to images of the nanoworld. A fascinating new exhibition "Blow-up: images from the nanoworld" in Modena/Italy shows the work of scientists associated with the National Center on Nanostructures and Biosystems at Surfaces in Modena, Italy, headed by Elisa Molinari. The images have been manipulated in a variety of ways by photographer, Lucia Covi. Covi is particularly sensible to the aesthetic paradigms of scientists: her gaze thus grasps essential aspects of the portrayed objects and allows her to shine them with a new light, as they are revealed now. This exhibition brings to the public images that are usually accessible to few, because they remain confined in the research laboratories, on the scientists' desks. The images are stills that, over time, have been put together from different framings, and that we can look at thanks to the mediation of machines. Some of them represent exceptional events, outstanding results that ended on the cover of scientific journals. Others were born from everyday research. All of them show a landscape that is being unraveled by scientists, scenery that is very different from the one we can see in the media, largely obtained through computer graphics and "artistic" interpretations, when not directly borrowed from science fiction.

The nanoworld cannot be portrayed with a camera, nor can it be seen even with the most powerful optical microscope. Only special instruments have access to images of the nanoworld. A fascinating new exhibition "Blow-up: images from the nanoworld" in Modena/Italy shows the work of scientists associated with the National Center on Nanostructures and Biosystems at Surfaces in Modena, Italy, headed by Elisa Molinari. The images have been manipulated in a variety of ways by photographer, Lucia Covi. Covi is particularly sensible to the aesthetic paradigms of scientists: her gaze thus grasps essential aspects of the portrayed objects and allows her to shine them with a new light, as they are revealed now. This exhibition brings to the public images that are usually accessible to few, because they remain confined in the research laboratories, on the scientists' desks. The images are stills that, over time, have been put together from different framings, and that we can look at thanks to the mediation of machines. Some of them represent exceptional events, outstanding results that ended on the cover of scientific journals. Others were born from everyday research. All of them show a landscape that is being unraveled by scientists, scenery that is very different from the one we can see in the media, largely obtained through computer graphics and "artistic" interpretations, when not directly borrowed from science fiction.

Dec 29th, 2006

The invention of the wheel was one of the most significant events in human history. It has been at the origin of major scientific and technological developments: from the creation of astronomical clocks or calculating machines to motor-drawn vehicles and other motor cars. At the molecular scale, the smallest at which a wheel can be created, it represents a major challenge for chemists and physicists. For years, scientists have been working on the design of molecular machines equipped with wheels. After observing the random rotation of a flat molecular wheel in 1998, designing and synthesizing a mono-molecular wheelbarrow in 2003 and then synthesizing a molecular motor in 2005, a European group of researchers managed to operate the first molecular rack with a pinion of 1.2 nm in diameter. They controlled the rotation of a 0.7 nm diameter wheel attached to a 0.6 nm-long axle in a molecule. This molecular 'wheel' could revolutionize machinery built at the nanoscale. Nanowheel rotation has been claimed before, but never shown directly.

The invention of the wheel was one of the most significant events in human history. It has been at the origin of major scientific and technological developments: from the creation of astronomical clocks or calculating machines to motor-drawn vehicles and other motor cars. At the molecular scale, the smallest at which a wheel can be created, it represents a major challenge for chemists and physicists. For years, scientists have been working on the design of molecular machines equipped with wheels. After observing the random rotation of a flat molecular wheel in 1998, designing and synthesizing a mono-molecular wheelbarrow in 2003 and then synthesizing a molecular motor in 2005, a European group of researchers managed to operate the first molecular rack with a pinion of 1.2 nm in diameter. They controlled the rotation of a 0.7 nm diameter wheel attached to a 0.6 nm-long axle in a molecule. This molecular 'wheel' could revolutionize machinery built at the nanoscale. Nanowheel rotation has been claimed before, but never shown directly.

Subscribe to our Nanotechnology Spotlight feed

Subscribe to our Nanotechnology Spotlight feed