Showing Spotlights 433 - 440 of 639 in category All (newest first):

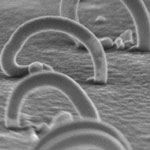

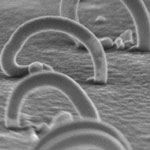

One of the ultimate goals of nanotechnology is to fabricate functional devices at the nanoscale. A nanodevice is expected to integrate components of different material compositions and geometries. The integration is likely to be carried out on silicon if information processing is required. Thus far, the basic building blocks for nanodevices are nanoparticles, for which there are many material candidates; and nanotubes, for which the candidates are fewer (they are mostly carbon, although non-carbon based tubes have been fabricated as well). One-dimensional (1-D) nanomaterials such as nanotubes are useful for component connection and for the transport of charge, heat and vibration. In addition to the limited material selection, common 1-D nanomaterials are usually straight. Composite 1-D nanomaterials are rarer. Often they are also produced as discrete and unorganized units. Scientists in Singapore have now successfully fabricated a family of aligned one-dimensional C-curved nanoarches of different compositions by a simple and scalable method for the first time.

One of the ultimate goals of nanotechnology is to fabricate functional devices at the nanoscale. A nanodevice is expected to integrate components of different material compositions and geometries. The integration is likely to be carried out on silicon if information processing is required. Thus far, the basic building blocks for nanodevices are nanoparticles, for which there are many material candidates; and nanotubes, for which the candidates are fewer (they are mostly carbon, although non-carbon based tubes have been fabricated as well). One-dimensional (1-D) nanomaterials such as nanotubes are useful for component connection and for the transport of charge, heat and vibration. In addition to the limited material selection, common 1-D nanomaterials are usually straight. Composite 1-D nanomaterials are rarer. Often they are also produced as discrete and unorganized units. Scientists in Singapore have now successfully fabricated a family of aligned one-dimensional C-curved nanoarches of different compositions by a simple and scalable method for the first time.

Jul 1st, 2009

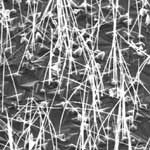

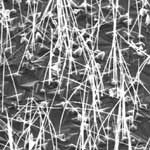

One of the outstanding challenges in nanotechnology generally, and in the exploitation of so-called 'bottom-up' assembly of basic nanoscale building blocks such as nanowires, is the development of techniques for assembling large numbers of such nanostructures into more complex systems and precisely specified patterns in an accurate, deterministic manner. For instance, it is possible to build transistors, optical devices, and sensors with very specific properties using nanowires. Thus many useful applications of nanowires will depend on the ability to take these building blocks and organize them in some deterministic way in order to ultimately construct and interface with a nanowire-based system. New work demonstrates the basic capability for, and elucidates some of the guiding principles in, the use of dielectrophoretic behavior to direct the placement of large numbers of nanowires on complex, pre-patterned structures as might be required for integration of nanowires with, for example, silicon-based microelectronic circuitry. It shows that a high level of placement precision can be achieved by paying careful attention to the signal frequency as well as the macroscopic electrode architecture that is employed.

One of the outstanding challenges in nanotechnology generally, and in the exploitation of so-called 'bottom-up' assembly of basic nanoscale building blocks such as nanowires, is the development of techniques for assembling large numbers of such nanostructures into more complex systems and precisely specified patterns in an accurate, deterministic manner. For instance, it is possible to build transistors, optical devices, and sensors with very specific properties using nanowires. Thus many useful applications of nanowires will depend on the ability to take these building blocks and organize them in some deterministic way in order to ultimately construct and interface with a nanowire-based system. New work demonstrates the basic capability for, and elucidates some of the guiding principles in, the use of dielectrophoretic behavior to direct the placement of large numbers of nanowires on complex, pre-patterned structures as might be required for integration of nanowires with, for example, silicon-based microelectronic circuitry. It shows that a high level of placement precision can be achieved by paying careful attention to the signal frequency as well as the macroscopic electrode architecture that is employed.

Jun 19th, 2009

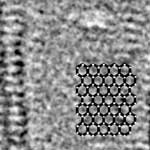

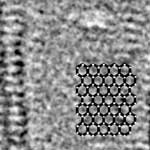

The manifold properties of carbon nanotubes (as well as other carbon nanomaterials such as fullerenes and graphene) are related to the various ways the carbon atoms can be arranged to form the tube lattice. Studies have shown that atomic-scale defects in these lattices can strongly influence the electronic and mechanical properties of the nanotubes. The simplest defect type is a vacancy where an atom is missing from the lattice site. Such defects can also be seen as chemically active sites for tube side wall functionalization. Due to the difficulty of observing vacancies directly, it remained unclear under what conditions vacancies in nanotubes are stable or exist at all. Researchers have now demonstrated a technique that allows them to remove carbon atoms from carbon nanotubes with atomic precision and in a controlled way with an extremely focused electron beam.

The manifold properties of carbon nanotubes (as well as other carbon nanomaterials such as fullerenes and graphene) are related to the various ways the carbon atoms can be arranged to form the tube lattice. Studies have shown that atomic-scale defects in these lattices can strongly influence the electronic and mechanical properties of the nanotubes. The simplest defect type is a vacancy where an atom is missing from the lattice site. Such defects can also be seen as chemically active sites for tube side wall functionalization. Due to the difficulty of observing vacancies directly, it remained unclear under what conditions vacancies in nanotubes are stable or exist at all. Researchers have now demonstrated a technique that allows them to remove carbon atoms from carbon nanotubes with atomic precision and in a controlled way with an extremely focused electron beam.

Jun 18th, 2009

The importance of novel markers for microcopy cannot be underestimated. Such markers can provide novel information about functioning of protein in cell. Owing to their unlimited photostability diamond nanoparticles can be used for long-term monitoring of intracellular processes. Diamond nanoparticles also appear to be ideal candidates for ultra microscopy techniques like STED. Furthermore, nitrogen-vacancy color centers in diamond have non-zero spin in the ground state. This allows their use as markers for magnetic resonance imaging with very high sensitivity. To date, few methods exist to produce diamond nanoparticles containing color centers (c-diamond), but they are only laboratory-scale. The most common, large-scale nanodiamond production method, detonation, produces diamond nanoparticles which do not contain any color centers but impurities such as surface-or lattice-aggregated nitrogen and metals in significant amounts. A German-French research team has now developed a high yield method for the large-scale production of fluorescent nanodiamonds.

The importance of novel markers for microcopy cannot be underestimated. Such markers can provide novel information about functioning of protein in cell. Owing to their unlimited photostability diamond nanoparticles can be used for long-term monitoring of intracellular processes. Diamond nanoparticles also appear to be ideal candidates for ultra microscopy techniques like STED. Furthermore, nitrogen-vacancy color centers in diamond have non-zero spin in the ground state. This allows their use as markers for magnetic resonance imaging with very high sensitivity. To date, few methods exist to produce diamond nanoparticles containing color centers (c-diamond), but they are only laboratory-scale. The most common, large-scale nanodiamond production method, detonation, produces diamond nanoparticles which do not contain any color centers but impurities such as surface-or lattice-aggregated nitrogen and metals in significant amounts. A German-French research team has now developed a high yield method for the large-scale production of fluorescent nanodiamonds.

Jun 9th, 2009

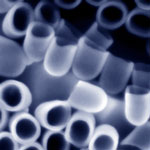

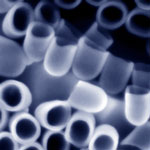

Many nanotechnology research efforts have explored the use of hollow nanochannels formed by carbon nanotubes (CNTs). However, the usually large length/diameter aspect ratio of CNTs has made it challenging to insert other materials into them in a controlled manner. A team of scientists has now developed the idea of using a nanocup morphology to solve this problem. The length/diameter ratio of these new graphitic architectures is 1,000 to 100,000 times smaller compared to conventional carbon nanotubes. This will allow researchers to build highly engineered and multicomponent functional nano building blocks for various applications including nanomedicine and nanometrology.

Many nanotechnology research efforts have explored the use of hollow nanochannels formed by carbon nanotubes (CNTs). However, the usually large length/diameter aspect ratio of CNTs has made it challenging to insert other materials into them in a controlled manner. A team of scientists has now developed the idea of using a nanocup morphology to solve this problem. The length/diameter ratio of these new graphitic architectures is 1,000 to 100,000 times smaller compared to conventional carbon nanotubes. This will allow researchers to build highly engineered and multicomponent functional nano building blocks for various applications including nanomedicine and nanometrology.

May 11th, 2009

Much effort has been invested into finding a non-toxic replacement for semiconductor quantum dots (Q-dots) possessing bright fluorescence. Intrinsic toxicity of Q-dots composed of elements such as selenium, tellurium, cadmium, and lead severely hinders their in vivo applications for fluorescent imaging. Therefore many carbon nanomaterials have been considered as a replacement for Q-dots for in vivo imaging. However, it is still unclear how safe carbon nanomaterials are, and this is an obstacle for their use in medicine. Nanodiamond has been an exception among nanomaterials in many aspects, but what is important for biomedical applications is that it has shown very little or zero toxicity in all tests done so far. In addition, nanodiamond powders are already produced by detonation on a large commercial scale. This is why fluorescent nanodiamonds currently attract so much attention.

Much effort has been invested into finding a non-toxic replacement for semiconductor quantum dots (Q-dots) possessing bright fluorescence. Intrinsic toxicity of Q-dots composed of elements such as selenium, tellurium, cadmium, and lead severely hinders their in vivo applications for fluorescent imaging. Therefore many carbon nanomaterials have been considered as a replacement for Q-dots for in vivo imaging. However, it is still unclear how safe carbon nanomaterials are, and this is an obstacle for their use in medicine. Nanodiamond has been an exception among nanomaterials in many aspects, but what is important for biomedical applications is that it has shown very little or zero toxicity in all tests done so far. In addition, nanodiamond powders are already produced by detonation on a large commercial scale. This is why fluorescent nanodiamonds currently attract so much attention.

Mar 30th, 2009

For the past 20+ years, the atomic force microscope has been one of the most important tools to visualize nanoscale objects where conventional optics cannot resolve them due to the wave nature of light. One limiting factor of conventional AFM operation is the speed at which images can be acquired. Over the past five years, researchers have been developing a high-speed AFM capable of video-rate image capture. An AFM with this ability enables nanoscale processes to be observed in real-time, rather than capturing only snap-shots in time. An obvious application of this instrument is to modify the sample surface while observing changes in the surface topography. Successful demonstration of this would indicate the potential for a new generation of fabrication tools. Scientists have now done exactly that.

For the past 20+ years, the atomic force microscope has been one of the most important tools to visualize nanoscale objects where conventional optics cannot resolve them due to the wave nature of light. One limiting factor of conventional AFM operation is the speed at which images can be acquired. Over the past five years, researchers have been developing a high-speed AFM capable of video-rate image capture. An AFM with this ability enables nanoscale processes to be observed in real-time, rather than capturing only snap-shots in time. An obvious application of this instrument is to modify the sample surface while observing changes in the surface topography. Successful demonstration of this would indicate the potential for a new generation of fabrication tools. Scientists have now done exactly that.

Mar 16th, 2009

Currently, all existing methods of fabricating CNT-polymer composites involve quite complicated, expensive, time-demanding processing techniques such as solution casting, melting, molding, extrusion, and in situ polymerization. In all of these techniques, nanotubes must either be incorporated into a polymer solution, molten polymer or mixed with the initial monomer before the formation of the final product. In addition, these methods can not be applied in the case of insoluble or temperature sensitive polymers, which decompose without melting. Kevlar is a well known high-strength polymer with a variety of important applications - think bullet-proof vests and car armor plating. However, Kevlar is not soluble in any common solvent and Kevlar fibers must be produced by wet spinning from sulphuric acid solutions. Researchers in Ireland have now found a way to develop a new effective post-processing technique which would allow to incorporate carbon nanotubes into already formed polymer products, such as for example Kevlar yarns.

Currently, all existing methods of fabricating CNT-polymer composites involve quite complicated, expensive, time-demanding processing techniques such as solution casting, melting, molding, extrusion, and in situ polymerization. In all of these techniques, nanotubes must either be incorporated into a polymer solution, molten polymer or mixed with the initial monomer before the formation of the final product. In addition, these methods can not be applied in the case of insoluble or temperature sensitive polymers, which decompose without melting. Kevlar is a well known high-strength polymer with a variety of important applications - think bullet-proof vests and car armor plating. However, Kevlar is not soluble in any common solvent and Kevlar fibers must be produced by wet spinning from sulphuric acid solutions. Researchers in Ireland have now found a way to develop a new effective post-processing technique which would allow to incorporate carbon nanotubes into already formed polymer products, such as for example Kevlar yarns.

Feb 25th, 2009

One of the ultimate goals of nanotechnology is to fabricate functional devices at the nanoscale. A nanodevice is expected to integrate components of different material compositions and geometries. The integration is likely to be carried out on silicon if information processing is required. Thus far, the basic building blocks for nanodevices are nanoparticles, for which there are many material candidates; and nanotubes, for which the candidates are fewer (they are mostly carbon, although non-carbon based tubes have been fabricated as well). One-dimensional (1-D) nanomaterials such as nanotubes are useful for component connection and for the transport of charge, heat and vibration. In addition to the limited material selection, common 1-D nanomaterials are usually straight. Composite 1-D nanomaterials are rarer. Often they are also produced as discrete and unorganized units. Scientists in Singapore have now successfully fabricated a family of aligned one-dimensional C-curved nanoarches of different compositions by a simple and scalable method for the first time.

One of the ultimate goals of nanotechnology is to fabricate functional devices at the nanoscale. A nanodevice is expected to integrate components of different material compositions and geometries. The integration is likely to be carried out on silicon if information processing is required. Thus far, the basic building blocks for nanodevices are nanoparticles, for which there are many material candidates; and nanotubes, for which the candidates are fewer (they are mostly carbon, although non-carbon based tubes have been fabricated as well). One-dimensional (1-D) nanomaterials such as nanotubes are useful for component connection and for the transport of charge, heat and vibration. In addition to the limited material selection, common 1-D nanomaterials are usually straight. Composite 1-D nanomaterials are rarer. Often they are also produced as discrete and unorganized units. Scientists in Singapore have now successfully fabricated a family of aligned one-dimensional C-curved nanoarches of different compositions by a simple and scalable method for the first time.

Subscribe to our Nanotechnology Spotlight feed

Subscribe to our Nanotechnology Spotlight feed