Showing Spotlights 337 - 344 of 639 in category All (newest first):

Vanadium dioxide (VO2) is a leading candidate material for the fabrication of thermochromic films and coatings that will find special applications in a new generation of 'smart' glass that can change infrared transmittance by responding to environmental temperature, while maintaining visible transparency. This kind of smart windows may be especially useful for locations with hot summers and/or cold winters. In addition to its temperature-responsive thermochromism these films also exhibit UV-shielding properties. Previously, we reported on a novel technique to fabricate large-area VO2 films suitable for mass production. The same research team has now developed an alternative technique for the large-scale, mass production of thermochromatic VO2 films.

Vanadium dioxide (VO2) is a leading candidate material for the fabrication of thermochromic films and coatings that will find special applications in a new generation of 'smart' glass that can change infrared transmittance by responding to environmental temperature, while maintaining visible transparency. This kind of smart windows may be especially useful for locations with hot summers and/or cold winters. In addition to its temperature-responsive thermochromism these films also exhibit UV-shielding properties. Previously, we reported on a novel technique to fabricate large-area VO2 films suitable for mass production. The same research team has now developed an alternative technique for the large-scale, mass production of thermochromatic VO2 films.

Feb 6th, 2012

Fabrication conditions for nanoscale field-effect transistors (nano-FETs) have to meet very high requirements in order for these transistors to be used reliably as ultrasensitive and label-free molecular sensors in medical and environmental applications. Current fabrication routes for silicon-nanowire sensor construction involve high-cost, high-complexity - and often low-yield - top-down techniques such as e-beam lithography and focused ion beam. An alternative, and lower-cost, fabrication method is the use of pre-synthesized nanotubes or nanowires that are integrated into microstructures to form nano-FET sensors. Now, researchers have developed an automated vision-based nanomanipulation technique that is capable of precisely controlling the number of nanowires incorporated into each device.

Fabrication conditions for nanoscale field-effect transistors (nano-FETs) have to meet very high requirements in order for these transistors to be used reliably as ultrasensitive and label-free molecular sensors in medical and environmental applications. Current fabrication routes for silicon-nanowire sensor construction involve high-cost, high-complexity - and often low-yield - top-down techniques such as e-beam lithography and focused ion beam. An alternative, and lower-cost, fabrication method is the use of pre-synthesized nanotubes or nanowires that are integrated into microstructures to form nano-FET sensors. Now, researchers have developed an automated vision-based nanomanipulation technique that is capable of precisely controlling the number of nanowires incorporated into each device.

Jan 24th, 2012

The huge economic impact of the corrosion of metallic structures is a very important issue for all modern societies. Estimates for the cost of corrosion degradation run to about 200 billion euros a year in Europe and over $270 billion a year in the U.S. The annual cost of corrosion consists of both direct costs and indirect costs. The direct costs are related to the costs of design, manufacturing, and construction in order to provide corrosion protection, and the indirect costs are concerned with corrosion-related inspection, maintenance and repairs. Researchers in Germany have now developed a novel and effective encapsulation system for metal protection against a wide range of biological and chemical aggressive agents.

The huge economic impact of the corrosion of metallic structures is a very important issue for all modern societies. Estimates for the cost of corrosion degradation run to about 200 billion euros a year in Europe and over $270 billion a year in the U.S. The annual cost of corrosion consists of both direct costs and indirect costs. The direct costs are related to the costs of design, manufacturing, and construction in order to provide corrosion protection, and the indirect costs are concerned with corrosion-related inspection, maintenance and repairs. Researchers in Germany have now developed a novel and effective encapsulation system for metal protection against a wide range of biological and chemical aggressive agents.

Jan 20th, 2012

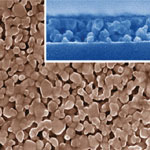

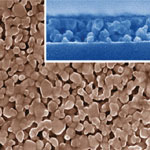

Vanadium dioxide (VO2) has long been recognized as a a material of significant technological interest for optics and electronics and a promising candidate for making 'smart' windows: it can transition from a transparent semiconductive state at low temperatures, allowing infrared radiation through, to an opaque metallic state at high temperatures, while still allowing visible light to get through. So far, VO2 hasn't been considered to be particularly suited for large-scale practical smart-window applications due to its low luminous transmittance and solar modulating ability. Researchers in China have now developed a process that can prepare VO2 thin-films with a controllable polymorph and morphology. Their results show that with increased porosity and decreased optical constants the performance of the VO2 films is enhanced, leading to a higher transmittance of visible light and improved solar modulating ability.

Vanadium dioxide (VO2) has long been recognized as a a material of significant technological interest for optics and electronics and a promising candidate for making 'smart' windows: it can transition from a transparent semiconductive state at low temperatures, allowing infrared radiation through, to an opaque metallic state at high temperatures, while still allowing visible light to get through. So far, VO2 hasn't been considered to be particularly suited for large-scale practical smart-window applications due to its low luminous transmittance and solar modulating ability. Researchers in China have now developed a process that can prepare VO2 thin-films with a controllable polymorph and morphology. Their results show that with increased porosity and decreased optical constants the performance of the VO2 films is enhanced, leading to a higher transmittance of visible light and improved solar modulating ability.

Dec 28th, 2011

Block copolymer lithography is a cost-effective, parallel, and scalable nanolithography for the densely packed periodic arrays of nanoscale features, whose typical dimension scale is beyond the resolution limit of conventional photolithography. So far, it has been impossible to utilize block copolymer lithography on low surface energy materials such as Teflon, graphene or gold, where block copolymer thin film generally de-wets. To address this technological challenge, researchers in South Korea introduced block copolymer lithography that employs polydopamine coating - inspired by the adhesive proteins secreted by mussels - as a surface pretreatment for universal wettability generally applicable to arbitrary surfaces.

Block copolymer lithography is a cost-effective, parallel, and scalable nanolithography for the densely packed periodic arrays of nanoscale features, whose typical dimension scale is beyond the resolution limit of conventional photolithography. So far, it has been impossible to utilize block copolymer lithography on low surface energy materials such as Teflon, graphene or gold, where block copolymer thin film generally de-wets. To address this technological challenge, researchers in South Korea introduced block copolymer lithography that employs polydopamine coating - inspired by the adhesive proteins secreted by mussels - as a surface pretreatment for universal wettability generally applicable to arbitrary surfaces.

Dec 15th, 2011

Currently, the primary tool for defining patterns at the micro- and nanometer scale is the mask aligner. Even where soft lithography methods are used, mask aligners are still often required to fabricate the masters. A mask aligner is a machine that is bulky in size and weight and is limited in the area that it can pattern in a single step. Also, a significant amount of infrastructure is needed for operation, such as high voltage power supplies and gas cooling lines. The average cost of this tool is in the six figures, which is a barrier for many labs and businesses in research and development of nanotechnologies. Researchers have now developed a compact and portable photolithography system based on a solid-state light source to remove these limiting factors and, at the same time, make available the high quality patterns that a mask aligner can produce.

Currently, the primary tool for defining patterns at the micro- and nanometer scale is the mask aligner. Even where soft lithography methods are used, mask aligners are still often required to fabricate the masters. A mask aligner is a machine that is bulky in size and weight and is limited in the area that it can pattern in a single step. Also, a significant amount of infrastructure is needed for operation, such as high voltage power supplies and gas cooling lines. The average cost of this tool is in the six figures, which is a barrier for many labs and businesses in research and development of nanotechnologies. Researchers have now developed a compact and portable photolithography system based on a solid-state light source to remove these limiting factors and, at the same time, make available the high quality patterns that a mask aligner can produce.

Dec 12th, 2011

Researchers have, for the first time, compared the energetic cost of silk and synthetic polymer fiber formation and demonstrated that, if we can learn how to spin like the spider, we should be able to cut the energy costs for polymer fiber processing by 90%, leaving alone the heat treatment requirements. The two routes of polymer fiber-spinning - one developed by nature and the other developed by man - show striking similarities: both start with liquid feed-stocks sharing comparable flow properties; in both cases the 'melts' are extruded through convergent dye designs; and for both 'spinning' results in highly ordered semicrystalline fibrous structures. In other words, analogous to the industrial melt spinning of a synthetic polymer, in the natural spinning of a silk the molecules (proteins) align (refold), nucleate (denature) and crystallize (aggregate).

Researchers have, for the first time, compared the energetic cost of silk and synthetic polymer fiber formation and demonstrated that, if we can learn how to spin like the spider, we should be able to cut the energy costs for polymer fiber processing by 90%, leaving alone the heat treatment requirements. The two routes of polymer fiber-spinning - one developed by nature and the other developed by man - show striking similarities: both start with liquid feed-stocks sharing comparable flow properties; in both cases the 'melts' are extruded through convergent dye designs; and for both 'spinning' results in highly ordered semicrystalline fibrous structures. In other words, analogous to the industrial melt spinning of a synthetic polymer, in the natural spinning of a silk the molecules (proteins) align (refold), nucleate (denature) and crystallize (aggregate).

Dec 7th, 2011

Directed self-assembly of block copolymers is a candidate lithography for use in future nanoelectronics and patterned media copolymer with resolutions down to the sub-10nm domain. Variations of this effective nanofabrication technique have been used to write periodic arrays of nanoscale features into substrates at exceptionally high densities with resolutions that are difficult or impossible to achieve with top-down techniques alone. However, in many cases these approaches are either too costly or too complex due to the required number of processing steps, for instance expensive, time-consuming substrate pre-patterning. Researchers at the Molecular Foundry have now shown that block copolymers can be aligned on an unpatterned substrate using a removable and reusable mold applied from above.

Directed self-assembly of block copolymers is a candidate lithography for use in future nanoelectronics and patterned media copolymer with resolutions down to the sub-10nm domain. Variations of this effective nanofabrication technique have been used to write periodic arrays of nanoscale features into substrates at exceptionally high densities with resolutions that are difficult or impossible to achieve with top-down techniques alone. However, in many cases these approaches are either too costly or too complex due to the required number of processing steps, for instance expensive, time-consuming substrate pre-patterning. Researchers at the Molecular Foundry have now shown that block copolymers can be aligned on an unpatterned substrate using a removable and reusable mold applied from above.

Dec 5th, 2011

Vanadium dioxide (VO2) is a leading candidate material for the fabrication of thermochromic films and coatings that will find special applications in a new generation of 'smart' glass that can change infrared transmittance by responding to environmental temperature, while maintaining visible transparency. This kind of smart windows may be especially useful for locations with hot summers and/or cold winters. In addition to its temperature-responsive thermochromism these films also exhibit UV-shielding properties. Previously, we reported on a novel technique to fabricate large-area VO2 films suitable for mass production. The same research team has now developed an alternative technique for the large-scale, mass production of thermochromatic VO2 films.

Vanadium dioxide (VO2) is a leading candidate material for the fabrication of thermochromic films and coatings that will find special applications in a new generation of 'smart' glass that can change infrared transmittance by responding to environmental temperature, while maintaining visible transparency. This kind of smart windows may be especially useful for locations with hot summers and/or cold winters. In addition to its temperature-responsive thermochromism these films also exhibit UV-shielding properties. Previously, we reported on a novel technique to fabricate large-area VO2 films suitable for mass production. The same research team has now developed an alternative technique for the large-scale, mass production of thermochromatic VO2 films.

Subscribe to our Nanotechnology Spotlight feed

Subscribe to our Nanotechnology Spotlight feed