Showing Spotlights 257 - 264 of 318 in category All (newest first):

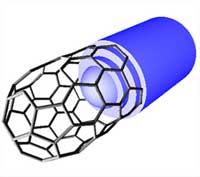

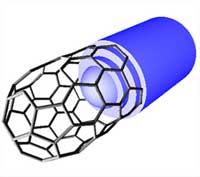

Scientists involved in cancer research are showing a lot of interest in carbon nanotubes (CNTs) to be used in basically three cancer-fighting areas. CNTs are being developed as targeted delivery vehicles for anticancer drugs right into cancer cells - think of really, really tiny injection needles. They are also used as the therapeutic agent itself; there is research that shows that CNTs can act as nanoscale bombs that literally blow apart a cancer cell. A third area of application is using CNTs as imaging agents.

Scientists involved in cancer research are showing a lot of interest in carbon nanotubes (CNTs) to be used in basically three cancer-fighting areas. CNTs are being developed as targeted delivery vehicles for anticancer drugs right into cancer cells - think of really, really tiny injection needles. They are also used as the therapeutic agent itself; there is research that shows that CNTs can act as nanoscale bombs that literally blow apart a cancer cell. A third area of application is using CNTs as imaging agents.

Jun 6th, 2007

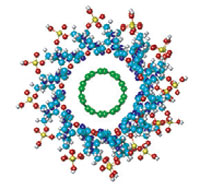

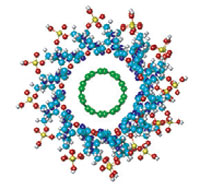

To achieve the full benefits of the amazing properties of carbon nanotubes (CNTs) researchers are exploring all kinds of CNT composite materials. Material engineers are interested because this will lead to lighter,stronger and tougher materials. Another fascinating area involves CNT/polymer composite structures that will lead to a vast range of improved and novel applications, from antistatic and EMI shielding to more efficient fuel and solar cells, to nanoelectronic devices. One particular area of CNT/polymer composites is dealing with DNA-CNTs hybrids. Although researchers expect a plethora of new applications, the fact that even the formation mechanism of these complexes is not yet clear shows how early in the game this research still is. This might be due to the fact that in spite of the quite large number of experimental investigations on the interaction between DNA and CNTs, the number of theoretical studies is limited. Researchers in Germany now present, for the first time, the results of a systematic quantum mechanical modeling of the stability and the electronic properties of complexes based on single-walled carbon nanotubes, which are helically wrapped by DNA molecules.

To achieve the full benefits of the amazing properties of carbon nanotubes (CNTs) researchers are exploring all kinds of CNT composite materials. Material engineers are interested because this will lead to lighter,stronger and tougher materials. Another fascinating area involves CNT/polymer composite structures that will lead to a vast range of improved and novel applications, from antistatic and EMI shielding to more efficient fuel and solar cells, to nanoelectronic devices. One particular area of CNT/polymer composites is dealing with DNA-CNTs hybrids. Although researchers expect a plethora of new applications, the fact that even the formation mechanism of these complexes is not yet clear shows how early in the game this research still is. This might be due to the fact that in spite of the quite large number of experimental investigations on the interaction between DNA and CNTs, the number of theoretical studies is limited. Researchers in Germany now present, for the first time, the results of a systematic quantum mechanical modeling of the stability and the electronic properties of complexes based on single-walled carbon nanotubes, which are helically wrapped by DNA molecules.

Jun 4th, 2007

Diesel-burning engines are a major contributor to environmental pollution. They emit a mixture of gases and fine particles that contain some 40, mostly toxic chemicals, including benzene, butadiene, dioxin and mercury compounds. Diesel exhaust is listed as a known or probable human carcinogen by several state and federal agencies in the United States. Wouldn't it be nice if we could render diesel soot harmless before it gets released into the environment? Wouldn't it even be nicer if we could use this soot to manufacture something useful? Japanese scientists have come up not only with a unique technique for effectively collecting diesel soot but also a method for using this soot as a precursor for the production of single-walled carbon nanotubes. How is that as a practical example for green nanotechnology?

Diesel-burning engines are a major contributor to environmental pollution. They emit a mixture of gases and fine particles that contain some 40, mostly toxic chemicals, including benzene, butadiene, dioxin and mercury compounds. Diesel exhaust is listed as a known or probable human carcinogen by several state and federal agencies in the United States. Wouldn't it be nice if we could render diesel soot harmless before it gets released into the environment? Wouldn't it even be nicer if we could use this soot to manufacture something useful? Japanese scientists have come up not only with a unique technique for effectively collecting diesel soot but also a method for using this soot as a precursor for the production of single-walled carbon nanotubes. How is that as a practical example for green nanotechnology?

May 30th, 2007

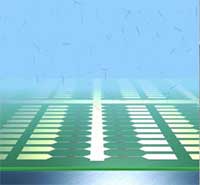

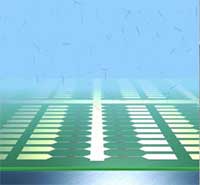

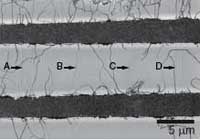

Over the next few years, semiconductor fabrication will move from the current state-of-the-art generation of 90 nanometer processes to the next 65 nm and 45 nm generations. Intel is even already working on 32 nm processor technology, code-named "Westmere", that is expected to hit the market sometime around 2009. The result of these efforts will be billion-transistor processors where a billion or more transistor-based circuits are integrated into a single chip. One of the increasingly difficult problems that chip designers are facing is that the high density of components packed on a chip makes interconnections increasingly difficult. In order to be able to continue the trend predicted by Moore's law, at least for a few more years, researchers are now turning to alternative materials for transistors and interconnect and one of the prime candidates for this job are single-walled carbon nanotubes (SWCNT). However, one of the biggest limitations of conventional carbon nanotube device fabrication techniques today is the inability to scale up the processes to fabricate a large number of devices on a single chip. Researchers in Germany have now demonstrated the directed and precise assembly of single-nanotube devices with an integration density of several million devices per square centimeter, using a novel aspect of nanotube dielectrophoresis. This development is a big step towards commercial realization of CNT-based electronic devices and their integration into the existing silicon-based processor technologies.

Over the next few years, semiconductor fabrication will move from the current state-of-the-art generation of 90 nanometer processes to the next 65 nm and 45 nm generations. Intel is even already working on 32 nm processor technology, code-named "Westmere", that is expected to hit the market sometime around 2009. The result of these efforts will be billion-transistor processors where a billion or more transistor-based circuits are integrated into a single chip. One of the increasingly difficult problems that chip designers are facing is that the high density of components packed on a chip makes interconnections increasingly difficult. In order to be able to continue the trend predicted by Moore's law, at least for a few more years, researchers are now turning to alternative materials for transistors and interconnect and one of the prime candidates for this job are single-walled carbon nanotubes (SWCNT). However, one of the biggest limitations of conventional carbon nanotube device fabrication techniques today is the inability to scale up the processes to fabricate a large number of devices on a single chip. Researchers in Germany have now demonstrated the directed and precise assembly of single-nanotube devices with an integration density of several million devices per square centimeter, using a novel aspect of nanotube dielectrophoresis. This development is a big step towards commercial realization of CNT-based electronic devices and their integration into the existing silicon-based processor technologies.

May 16th, 2007

Current production methods for carbon nanotubes (CNT) result in units with different diameter, length, chirality and electronic properties, all packed together in bundles, and often blended with some amount of amorphous carbon. The separation of nanotubes according to desired properties remains a technical challenge. Especially single-walled carbon nanotube (SWCNT) sorting is a challenge because the composition and chemical properties of SWCNTs of different types are very similar, making conventional separation techniques inefficient. In order to find ways to control nanotube diameter and chirality it would be necessary to monitor nanotube growth. Then, if one knew exactly how to grow nanotubes of different characteristics, one could control their electronic properties because, depending on the way the carbon atoms are arrange around the 'waist' of a nanotube, the electronic properties could vary from metallic to semiconducting. An international group of researchers has demonstrated a novel approach to use nanotubes as reaction cells, enabling them to monitor the birth and growth of carbon nanotubes, and taking some spectacular image of this process.

Current production methods for carbon nanotubes (CNT) result in units with different diameter, length, chirality and electronic properties, all packed together in bundles, and often blended with some amount of amorphous carbon. The separation of nanotubes according to desired properties remains a technical challenge. Especially single-walled carbon nanotube (SWCNT) sorting is a challenge because the composition and chemical properties of SWCNTs of different types are very similar, making conventional separation techniques inefficient. In order to find ways to control nanotube diameter and chirality it would be necessary to monitor nanotube growth. Then, if one knew exactly how to grow nanotubes of different characteristics, one could control their electronic properties because, depending on the way the carbon atoms are arrange around the 'waist' of a nanotube, the electronic properties could vary from metallic to semiconducting. An international group of researchers has demonstrated a novel approach to use nanotubes as reaction cells, enabling them to monitor the birth and growth of carbon nanotubes, and taking some spectacular image of this process.

May 10th, 2007

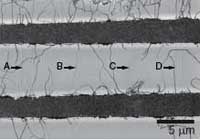

Synthesis of carbon nanotubes (CNTs) is a rapidly advancing field, but there is a lot that researchers don't know about how nanotubes form and grow. Synthesis, while rapidly developing, is currently the weakest link for most nanotube applications, with high yield and high precision diameter and chirality control being important goals. Historically, in situ characterization tools have accelerated progress in synthesis for many advanced materials, and there is widespread recognition that in situ tools have the potential to improve CNT synthesis as well. Ideally one would like to detect individual nanotubes and ensembles as they grow and measure their physical properties while imposing minimal constraints on the synthesis method. In other words, with a good understanding of the synthesis process we would be better able to control the product. It is feasible that by actually observing nanotubes as they grow one will gain a better understanding of the growth process and also better characterize the grown product. Greater control over the physical characteristics of the nanotube product is essential to enable many applications, as well as many fundamental studies. Although chemical vapor deposition (CVD) is now a very standard method to synthesize CNTs, there aren't really standard in situ tools to characterize nanotubes during growth. Researchers in Canada have now shown how global Raman imaging (GRI) can be used to characterize the CVD growth of CNTs in situ and in real time.

Synthesis of carbon nanotubes (CNTs) is a rapidly advancing field, but there is a lot that researchers don't know about how nanotubes form and grow. Synthesis, while rapidly developing, is currently the weakest link for most nanotube applications, with high yield and high precision diameter and chirality control being important goals. Historically, in situ characterization tools have accelerated progress in synthesis for many advanced materials, and there is widespread recognition that in situ tools have the potential to improve CNT synthesis as well. Ideally one would like to detect individual nanotubes and ensembles as they grow and measure their physical properties while imposing minimal constraints on the synthesis method. In other words, with a good understanding of the synthesis process we would be better able to control the product. It is feasible that by actually observing nanotubes as they grow one will gain a better understanding of the growth process and also better characterize the grown product. Greater control over the physical characteristics of the nanotube product is essential to enable many applications, as well as many fundamental studies. Although chemical vapor deposition (CVD) is now a very standard method to synthesize CNTs, there aren't really standard in situ tools to characterize nanotubes during growth. Researchers in Canada have now shown how global Raman imaging (GRI) can be used to characterize the CVD growth of CNTs in situ and in real time.

Apr 26th, 2007

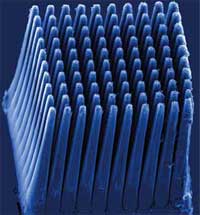

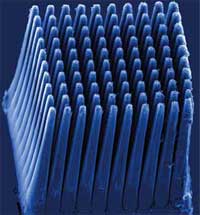

For computer chips, 'smaller and faster' just isn't good enough anymore. Power and heat have become the biggest issues for chip manufacturers and companies integrating these chips in everyday devices such as cell phones and laptops. The computing power of today's computer chips is provided mostly by operations switching at ever higher frequency. This physically induced power dissipation represents the limiting factor to a further increase of the capability of integrated circuits. Heat dissipation of the latest Intel processors has become a widely discussed issue. By the end of the decade, you might as well be feeling a rocket nozzle than touching a chip. And soon after 2010, computer chips could feel like the bubbly hot surface of the sun itself. As the electronics industry continues to churn out smaller and slimmer portable devices, manufacturers have been challenged to find new ways to combat the persistent problem of thermal management. New research suggests that the integration of carbon nanotubes (CNTs) as heat sinks into electronic devices might provide a solution to this problem.

For computer chips, 'smaller and faster' just isn't good enough anymore. Power and heat have become the biggest issues for chip manufacturers and companies integrating these chips in everyday devices such as cell phones and laptops. The computing power of today's computer chips is provided mostly by operations switching at ever higher frequency. This physically induced power dissipation represents the limiting factor to a further increase of the capability of integrated circuits. Heat dissipation of the latest Intel processors has become a widely discussed issue. By the end of the decade, you might as well be feeling a rocket nozzle than touching a chip. And soon after 2010, computer chips could feel like the bubbly hot surface of the sun itself. As the electronics industry continues to churn out smaller and slimmer portable devices, manufacturers have been challenged to find new ways to combat the persistent problem of thermal management. New research suggests that the integration of carbon nanotubes (CNTs) as heat sinks into electronic devices might provide a solution to this problem.

Apr 12th, 2007

The assembly of nanoparticles along the external or internal surface of carbon nanotubes (CNTs) is of both fundamental and technological interest. Combining unique properties of CNTs and nanoparticles, the nanoparticle/nanotube composite structure attracts a broad range of advanced applications, including nanoelectronics, chemical and biosensors, catalysis and fuel cells. This so-called 'decoration' of CNTs has been used to increase the hydrogen storage capacity, to make nanotubes magnetic, or to grow secondary structures inside the nanotubes to increase the available surface for catalysis. In the case of interior wall decoration of CNTs, the internal cavity of the nanotube often is obstructed and no flow can be achieved or there could be release of the particles in the environment. In the case of exterior wall decorations, the particles enter in direct contact with the environment and may be lost during the nanotube handling. A novel technique of multifunctional nanotubes with controllable amounts of nanoparticles embedded in their walls during the synthesis process solves both problems leaving the CNT bore accessible and keeping the nanoparticles shielded from the environment by the CNT walls. This paves the way to using carbon nanotubes as nanoscale biological probes for sub-cellular investigation.

The assembly of nanoparticles along the external or internal surface of carbon nanotubes (CNTs) is of both fundamental and technological interest. Combining unique properties of CNTs and nanoparticles, the nanoparticle/nanotube composite structure attracts a broad range of advanced applications, including nanoelectronics, chemical and biosensors, catalysis and fuel cells. This so-called 'decoration' of CNTs has been used to increase the hydrogen storage capacity, to make nanotubes magnetic, or to grow secondary structures inside the nanotubes to increase the available surface for catalysis. In the case of interior wall decoration of CNTs, the internal cavity of the nanotube often is obstructed and no flow can be achieved or there could be release of the particles in the environment. In the case of exterior wall decorations, the particles enter in direct contact with the environment and may be lost during the nanotube handling. A novel technique of multifunctional nanotubes with controllable amounts of nanoparticles embedded in their walls during the synthesis process solves both problems leaving the CNT bore accessible and keeping the nanoparticles shielded from the environment by the CNT walls. This paves the way to using carbon nanotubes as nanoscale biological probes for sub-cellular investigation.

Mar 16th, 2007

Scientists involved in cancer research are showing a lot of interest in carbon nanotubes (CNTs) to be used in basically three cancer-fighting areas. CNTs are being developed as targeted delivery vehicles for anticancer drugs right into cancer cells - think of really, really tiny injection needles. They are also used as the therapeutic agent itself; there is research that shows that CNTs can act as nanoscale bombs that literally blow apart a cancer cell. A third area of application is using CNTs as imaging agents.

Scientists involved in cancer research are showing a lot of interest in carbon nanotubes (CNTs) to be used in basically three cancer-fighting areas. CNTs are being developed as targeted delivery vehicles for anticancer drugs right into cancer cells - think of really, really tiny injection needles. They are also used as the therapeutic agent itself; there is research that shows that CNTs can act as nanoscale bombs that literally blow apart a cancer cell. A third area of application is using CNTs as imaging agents.

Subscribe to our Nanotechnology Spotlight feed

Subscribe to our Nanotechnology Spotlight feed