Showing Spotlights 241 - 248 of 318 in category All (newest first):

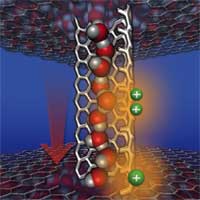

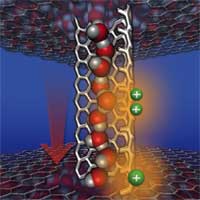

Nanofluidic channels, confining and transporting tiny amounts of fluid, are the pipelines that make the cellular activities of organisms possible. Nanoscale channels carry nutrients into cells and waste from cells and they also transport water into and out of the cell. Body temperature, digestion, reproduction, fluid pressure in the eye, and water conservation in the kidney are only a few of the processes in humans that depend on the proper functioning of cellular water channels. Special proteins called aquaporins can transport water through the cell membrane at a high rate while effectively blocking everything else - even individual protons, the nuclei of hydrogen atoms. The aquaporin channels are so narrow that no molecule larger than water can pass through, effectively forcing them through like beads on a chain. A unique distribution of amino acid residues along the pore wall also accounts for the channel's ability to move water quickly. To keep out molecules smaller than water there is also a chemical filter, formed by the specific orientation and distribution of the amino acid residues lining the pore. Thus water, and only water, flows freely through the aquaporin nanochannels, the direction of flow depending only on changing relative pressure inside and outside the cell. This intriguing mechanism has attracted the attention of nanotechnology researchers who see it as a blueprint for the construction of nanoscale water pumps. A molecular dynamics simulation conducted by Chinese researchers proposes a design for such a molecular pump constructed with a carbon nanotube.

Nanofluidic channels, confining and transporting tiny amounts of fluid, are the pipelines that make the cellular activities of organisms possible. Nanoscale channels carry nutrients into cells and waste from cells and they also transport water into and out of the cell. Body temperature, digestion, reproduction, fluid pressure in the eye, and water conservation in the kidney are only a few of the processes in humans that depend on the proper functioning of cellular water channels. Special proteins called aquaporins can transport water through the cell membrane at a high rate while effectively blocking everything else - even individual protons, the nuclei of hydrogen atoms. The aquaporin channels are so narrow that no molecule larger than water can pass through, effectively forcing them through like beads on a chain. A unique distribution of amino acid residues along the pore wall also accounts for the channel's ability to move water quickly. To keep out molecules smaller than water there is also a chemical filter, formed by the specific orientation and distribution of the amino acid residues lining the pore. Thus water, and only water, flows freely through the aquaporin nanochannels, the direction of flow depending only on changing relative pressure inside and outside the cell. This intriguing mechanism has attracted the attention of nanotechnology researchers who see it as a blueprint for the construction of nanoscale water pumps. A molecular dynamics simulation conducted by Chinese researchers proposes a design for such a molecular pump constructed with a carbon nanotube.

Nov 9th, 2007

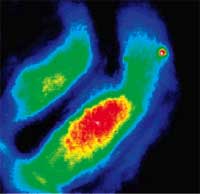

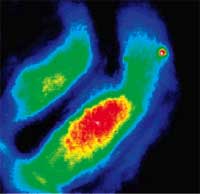

Nanotechnology's poster child, the carbon nanotube (CNT), has been explored for use in many technical applications. Increasingly, researchers are also looking at the unique biological properties of CNTs for potential biomedical uses. For instance, the interaction between DNA and CNTs have been explored and DNA-functionalized nanotubes hold significant promise as nucleic acid sensors. Nanotubes have also been considered for use as scaffolds for cells in tissue engineering. No matter what their intended function, any material used in medicine must exhibit - among other compatibility factors - biocompatibility, non-toxicity and non-carcinogenicity. And here the jury is still out as far as CNTs are concerned. One limiting factor of toxicological studies so far has been the use of animal tissue rather than living specimen. Researchers have now succeeded in detecting single-walled CNTs (SWCNTs) inside living animals - with surprisingly benign results - paving the way for future research on the effects and fate of nanotubes inside living organisms.

Nanotechnology's poster child, the carbon nanotube (CNT), has been explored for use in many technical applications. Increasingly, researchers are also looking at the unique biological properties of CNTs for potential biomedical uses. For instance, the interaction between DNA and CNTs have been explored and DNA-functionalized nanotubes hold significant promise as nucleic acid sensors. Nanotubes have also been considered for use as scaffolds for cells in tissue engineering. No matter what their intended function, any material used in medicine must exhibit - among other compatibility factors - biocompatibility, non-toxicity and non-carcinogenicity. And here the jury is still out as far as CNTs are concerned. One limiting factor of toxicological studies so far has been the use of animal tissue rather than living specimen. Researchers have now succeeded in detecting single-walled CNTs (SWCNTs) inside living animals - with surprisingly benign results - paving the way for future research on the effects and fate of nanotubes inside living organisms.

Nov 7th, 2007

Animals that cling to walls and walk on ceilings owe this ability to micro- and nanoscale attachment elements. The highest adhesion forces are encountered in geckos. For centuries, the ability of geckos to climb any vertical surface or hang from ceilings with one toe has always generated considerable interest. A gecko is the heaviest animal that can 'stand' on a ceiling, with its feet over its head. This is why scientists are intensely researching the adhesive system of the tiny hairs on its feet. On the sole of a gecko's toes there are some one billion tiny adhesive hairs called setae (3-130 micrometers in length), splitting into even smaller spatulae (about 200 nanometers in both width and length) at the end. It was found that these elastic hairs induce strong van der Waals forces. This finding has prompted many researchers to use synthetic microarrays to mimic gecko feet. Recent work, mainly from A. Dhinojwala, P.M. Ajayan, M. Meyyappan, and L. Dai groups, as well as the Max Planck Institute for Metals Research in Germany (see our previous Spotlight: Gecko nanotechnology), has indicated that aligned carbon nanotubes (CNTs) sticking out of substrate surfaces showed strong nanometer-scale adhesion forces. Although carbon nanotubes are thousands of times thinner than a human hair, they can be stronger than steel, lighter than plastic, more conductive than copper for electricity and diamond for heat. Applications of such bio-inspired development of artificial dry adhesive systems with aligned carbon nanotubes could range from low-tech fridge magnets to holding together electronics or even airplane parts.

Animals that cling to walls and walk on ceilings owe this ability to micro- and nanoscale attachment elements. The highest adhesion forces are encountered in geckos. For centuries, the ability of geckos to climb any vertical surface or hang from ceilings with one toe has always generated considerable interest. A gecko is the heaviest animal that can 'stand' on a ceiling, with its feet over its head. This is why scientists are intensely researching the adhesive system of the tiny hairs on its feet. On the sole of a gecko's toes there are some one billion tiny adhesive hairs called setae (3-130 micrometers in length), splitting into even smaller spatulae (about 200 nanometers in both width and length) at the end. It was found that these elastic hairs induce strong van der Waals forces. This finding has prompted many researchers to use synthetic microarrays to mimic gecko feet. Recent work, mainly from A. Dhinojwala, P.M. Ajayan, M. Meyyappan, and L. Dai groups, as well as the Max Planck Institute for Metals Research in Germany (see our previous Spotlight: Gecko nanotechnology), has indicated that aligned carbon nanotubes (CNTs) sticking out of substrate surfaces showed strong nanometer-scale adhesion forces. Although carbon nanotubes are thousands of times thinner than a human hair, they can be stronger than steel, lighter than plastic, more conductive than copper for electricity and diamond for heat. Applications of such bio-inspired development of artificial dry adhesive systems with aligned carbon nanotubes could range from low-tech fridge magnets to holding together electronics or even airplane parts.

Nov 5th, 2007

Granted, they don't sell them at Gap yet, but if current research undertaken by scientists in Australia is any indication, bullet-proof vests as light as T-shirts could become reality in the not too-distant future. Carbon nanotubes (CNTs) have great potential applications in making ballistic-resistance materials. The remarkable properties of CNTs makes them an ideal candidate for reinforcing polymers and other materials, and could lead to applications such as ligh-weight bullet-proof vests or shields for military vehicles and spacecraft. For these applications, thinner, lighter, and more flexible materials with superior dynamic mechanical properties are required than what is currently available. Ongoing research at the University of Sydney explores the energy absorption capacity of single-walled carbon nanotubes under a ballistic impact. CNT reinforced materials might not only be very effective in stopping ballistic penetration or high speed impact, like Kevlar vests, but they might also be able to prevent the blunt force trauma that still is a problem with today's body armor.

Granted, they don't sell them at Gap yet, but if current research undertaken by scientists in Australia is any indication, bullet-proof vests as light as T-shirts could become reality in the not too-distant future. Carbon nanotubes (CNTs) have great potential applications in making ballistic-resistance materials. The remarkable properties of CNTs makes them an ideal candidate for reinforcing polymers and other materials, and could lead to applications such as ligh-weight bullet-proof vests or shields for military vehicles and spacecraft. For these applications, thinner, lighter, and more flexible materials with superior dynamic mechanical properties are required than what is currently available. Ongoing research at the University of Sydney explores the energy absorption capacity of single-walled carbon nanotubes under a ballistic impact. CNT reinforced materials might not only be very effective in stopping ballistic penetration or high speed impact, like Kevlar vests, but they might also be able to prevent the blunt force trauma that still is a problem with today's body armor.

Nov 1st, 2007

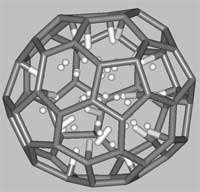

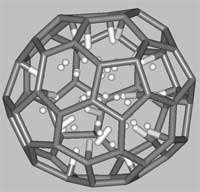

In our Spotlight on the issues of moving to hydrogen-powered cars (Nanotechnology could clean up the hydrogen car's dirty little secret) we briefly touched upon the problem of storing hydrogen onboard a vehicle. One gram of hydrogen gas will allow you to drive about 100 meters; unfortunately this single gram occupies almost 11 liters (2.9 gallons) of volume at room temperature and atmospheric pressure. In order to match today's cars' average reach of 400-500 kilometers per tank filling you would need to store 4 to 5 kg, or 40,000 to 50,000 liters, of hydrogen in your car. This is doable, but complicated and inconvenient, either by using intense pressure of several hundred atmospheres to store hydrogen as gas, or under cryogenic temperatures (minus 253 degrees centigrade) to store it in liquid form. Both alternatives have drawbacks. An intriguing nanotechnology approach to hydrogen storage is to encapsulate hydrogen inside hollow molecules, under room temperature. Fullerenes are ideal nanocages for this purpose, not only because they are hollow but also because hydrogen can be adsorbed on the fullerene surface. A new theoretical study provides the most accurate method to date for the structural optimization of such hydrogen-C60 composites, allowing to predict the hydrogen content in fullerene nanocages and their corresponding stability.

In our Spotlight on the issues of moving to hydrogen-powered cars (Nanotechnology could clean up the hydrogen car's dirty little secret) we briefly touched upon the problem of storing hydrogen onboard a vehicle. One gram of hydrogen gas will allow you to drive about 100 meters; unfortunately this single gram occupies almost 11 liters (2.9 gallons) of volume at room temperature and atmospheric pressure. In order to match today's cars' average reach of 400-500 kilometers per tank filling you would need to store 4 to 5 kg, or 40,000 to 50,000 liters, of hydrogen in your car. This is doable, but complicated and inconvenient, either by using intense pressure of several hundred atmospheres to store hydrogen as gas, or under cryogenic temperatures (minus 253 degrees centigrade) to store it in liquid form. Both alternatives have drawbacks. An intriguing nanotechnology approach to hydrogen storage is to encapsulate hydrogen inside hollow molecules, under room temperature. Fullerenes are ideal nanocages for this purpose, not only because they are hollow but also because hydrogen can be adsorbed on the fullerene surface. A new theoretical study provides the most accurate method to date for the structural optimization of such hydrogen-C60 composites, allowing to predict the hydrogen content in fullerene nanocages and their corresponding stability.

Oct 19th, 2007

Modern nanotechnology researchers not only borrow extensively from nature to develop new materials and fabrication techniques, they also manage to transfer proven, and sometimes ancient, technologies into their nanotechnology laboratories. We've written about this before in our stories about welding ("Bronze Age technique works just fine in the nanotechnology era") and metal forging ("From Bronze Age shack to nanotechnology lab - metal forging techniques reach the bottom"). Today, our story deals with yet another ur-technology: spinning. Spinning is the process of creating yarn (or thread, rope, cable) from various raw fiber materials. The first spinning wheel was invented in India probably some 2,500-3,000 years ago, although some claim that the Chinese used similar devices as long as almost 5,000 years ago to spin silk threads. While spinning is one of the core technology foundations of our civilization, researchers have now begun to apply cotton-spinning techniques to fabricate carbon nanotube (CNT) "yarn."

Modern nanotechnology researchers not only borrow extensively from nature to develop new materials and fabrication techniques, they also manage to transfer proven, and sometimes ancient, technologies into their nanotechnology laboratories. We've written about this before in our stories about welding ("Bronze Age technique works just fine in the nanotechnology era") and metal forging ("From Bronze Age shack to nanotechnology lab - metal forging techniques reach the bottom"). Today, our story deals with yet another ur-technology: spinning. Spinning is the process of creating yarn (or thread, rope, cable) from various raw fiber materials. The first spinning wheel was invented in India probably some 2,500-3,000 years ago, although some claim that the Chinese used similar devices as long as almost 5,000 years ago to spin silk threads. While spinning is one of the core technology foundations of our civilization, researchers have now begun to apply cotton-spinning techniques to fabricate carbon nanotube (CNT) "yarn."

Oct 4th, 2007

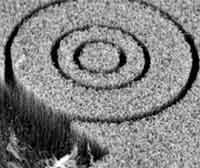

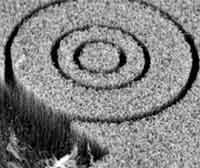

Just kidding - I always wanted to write a tabloid headline like that! In case you are expecting a story on the mysteries of crop circles caused by alien nanotechnology - stop reading right here; but the analogy is just too striking when you look at the amazing images coming out of the labs at the University of Southern California, where they developed a new technique to create three-dimensional carbon nanotube structures. While carbon nanotubes possess many exceptional properties which far exceed most known bulk materials, creating controlled nanotube (CNT) microstructures has always been a challenge. Overcoming this challenge is going to be key in developing useful and commercially viable CNT devices. Existing techniques for patterning three-dimensional CNT structures are based on the bottom-up growth of multiwalled CNTs (MWCNTs) from a patterned catalyst, which is limited to 2D-like geometries. Other, complex 3D microstructures have been fabricated with polymer-based resin materials but not with CNTs. The new technique developed by researchers in California uses a focused laser beam to selectively burn local regions of a dense forest of MWCNTs. This technique enables chemically sensitive fields to take advantage of nanotubes' exceptional properties and expand their possible applications into new areas.

Just kidding - I always wanted to write a tabloid headline like that! In case you are expecting a story on the mysteries of crop circles caused by alien nanotechnology - stop reading right here; but the analogy is just too striking when you look at the amazing images coming out of the labs at the University of Southern California, where they developed a new technique to create three-dimensional carbon nanotube structures. While carbon nanotubes possess many exceptional properties which far exceed most known bulk materials, creating controlled nanotube (CNT) microstructures has always been a challenge. Overcoming this challenge is going to be key in developing useful and commercially viable CNT devices. Existing techniques for patterning three-dimensional CNT structures are based on the bottom-up growth of multiwalled CNTs (MWCNTs) from a patterned catalyst, which is limited to 2D-like geometries. Other, complex 3D microstructures have been fabricated with polymer-based resin materials but not with CNTs. The new technique developed by researchers in California uses a focused laser beam to selectively burn local regions of a dense forest of MWCNTs. This technique enables chemically sensitive fields to take advantage of nanotubes' exceptional properties and expand their possible applications into new areas.

Sep 21st, 2007

Firefighters and stuntmen certainly appreciate the fire resistant capabilities of modern textiles. Going far beyond such niche use, flame retardant materials have become a major business for the chemical industry and can be found practically everywhere in modern society. If you live in a country where houses are mostly built from wood (like in the U.S.; where, on the other hand, the things that used to be wood are now plastic - like christmas trees; flame retardant ones of course) most structural timber and wood elements such as paneling are treated to make them more fire resistant. Plastic materials are replacing traditional materials like wood and metal - just look at the toys you played with and the ones your kids have today. Unfortunately, the synthetic polymeric materials we group under the term 'plastic' are flammable. To decrease their flammability they require the addition of flame-retardant chemical compounds. The plastic casings, circuit boards and cables of your computers, electrical appliances or car are flame retardant. So is practically every material in airplanes, trains and ships from the fabric of seats to every kind of plastic structure found onboard. Name any plastic product and chances are it has been made flame retardant. Conventional methods for making plastic flame retardant involve a range of not exactly harmless chemicals. Improving the flame retardancy of polymeric materials without the use of toxic chemicals could now become possible thanks to the synergistic effect of carbon nanotubes and clay.

Firefighters and stuntmen certainly appreciate the fire resistant capabilities of modern textiles. Going far beyond such niche use, flame retardant materials have become a major business for the chemical industry and can be found practically everywhere in modern society. If you live in a country where houses are mostly built from wood (like in the U.S.; where, on the other hand, the things that used to be wood are now plastic - like christmas trees; flame retardant ones of course) most structural timber and wood elements such as paneling are treated to make them more fire resistant. Plastic materials are replacing traditional materials like wood and metal - just look at the toys you played with and the ones your kids have today. Unfortunately, the synthetic polymeric materials we group under the term 'plastic' are flammable. To decrease their flammability they require the addition of flame-retardant chemical compounds. The plastic casings, circuit boards and cables of your computers, electrical appliances or car are flame retardant. So is practically every material in airplanes, trains and ships from the fabric of seats to every kind of plastic structure found onboard. Name any plastic product and chances are it has been made flame retardant. Conventional methods for making plastic flame retardant involve a range of not exactly harmless chemicals. Improving the flame retardancy of polymeric materials without the use of toxic chemicals could now become possible thanks to the synergistic effect of carbon nanotubes and clay.

Aug 30th, 2007

Nanofluidic channels, confining and transporting tiny amounts of fluid, are the pipelines that make the cellular activities of organisms possible. Nanoscale channels carry nutrients into cells and waste from cells and they also transport water into and out of the cell. Body temperature, digestion, reproduction, fluid pressure in the eye, and water conservation in the kidney are only a few of the processes in humans that depend on the proper functioning of cellular water channels. Special proteins called aquaporins can transport water through the cell membrane at a high rate while effectively blocking everything else - even individual protons, the nuclei of hydrogen atoms. The aquaporin channels are so narrow that no molecule larger than water can pass through, effectively forcing them through like beads on a chain. A unique distribution of amino acid residues along the pore wall also accounts for the channel's ability to move water quickly. To keep out molecules smaller than water there is also a chemical filter, formed by the specific orientation and distribution of the amino acid residues lining the pore. Thus water, and only water, flows freely through the aquaporin nanochannels, the direction of flow depending only on changing relative pressure inside and outside the cell. This intriguing mechanism has attracted the attention of nanotechnology researchers who see it as a blueprint for the construction of nanoscale water pumps. A molecular dynamics simulation conducted by Chinese researchers proposes a design for such a molecular pump constructed with a carbon nanotube.

Nanofluidic channels, confining and transporting tiny amounts of fluid, are the pipelines that make the cellular activities of organisms possible. Nanoscale channels carry nutrients into cells and waste from cells and they also transport water into and out of the cell. Body temperature, digestion, reproduction, fluid pressure in the eye, and water conservation in the kidney are only a few of the processes in humans that depend on the proper functioning of cellular water channels. Special proteins called aquaporins can transport water through the cell membrane at a high rate while effectively blocking everything else - even individual protons, the nuclei of hydrogen atoms. The aquaporin channels are so narrow that no molecule larger than water can pass through, effectively forcing them through like beads on a chain. A unique distribution of amino acid residues along the pore wall also accounts for the channel's ability to move water quickly. To keep out molecules smaller than water there is also a chemical filter, formed by the specific orientation and distribution of the amino acid residues lining the pore. Thus water, and only water, flows freely through the aquaporin nanochannels, the direction of flow depending only on changing relative pressure inside and outside the cell. This intriguing mechanism has attracted the attention of nanotechnology researchers who see it as a blueprint for the construction of nanoscale water pumps. A molecular dynamics simulation conducted by Chinese researchers proposes a design for such a molecular pump constructed with a carbon nanotube.

Subscribe to our Nanotechnology Spotlight feed

Subscribe to our Nanotechnology Spotlight feed