Showing Spotlights 81 - 88 of 318 in category All (newest first):

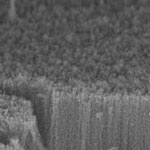

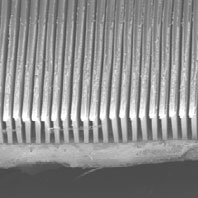

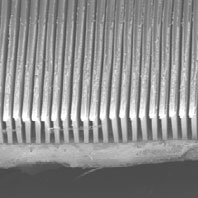

Heat has become one of the most critical issues in computer and semiconductor design. Three factors are playing the most important role in a microscale heat sink cooling system: the thermal conductivity of the material of the cooling fins; the heat exchange area of the cooling fins; and the convection between cooling fins and ambient. Carbon nanotubes satisfy the first two factors very well. They possess very high thermal conductivity and very high surface/volume ratio among other outstanding physical properties such as light, high current carrying capacity, excellent mechanical strength, etc. To reduce high temperatures, today's heat sinks are attached to the back of the chips to pull thermal energy away from the microprocessor and transfer it into the surrounding air. Researchers have now demonstrated the application of interface-enhanced CNTs as on-chip cooling fins in a microchannel heat sink.

Heat has become one of the most critical issues in computer and semiconductor design. Three factors are playing the most important role in a microscale heat sink cooling system: the thermal conductivity of the material of the cooling fins; the heat exchange area of the cooling fins; and the convection between cooling fins and ambient. Carbon nanotubes satisfy the first two factors very well. They possess very high thermal conductivity and very high surface/volume ratio among other outstanding physical properties such as light, high current carrying capacity, excellent mechanical strength, etc. To reduce high temperatures, today's heat sinks are attached to the back of the chips to pull thermal energy away from the microprocessor and transfer it into the surrounding air. Researchers have now demonstrated the application of interface-enhanced CNTs as on-chip cooling fins in a microchannel heat sink.

Jan 13th, 2012

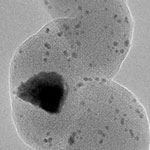

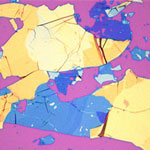

A number of parameters are known to affect the synthesis of carbon nanomaterials, such as the composition and size of the catalysts, type of hydrocarbon gas, temperature, and reaction time. Different carbon nanomaterials having various carbon atomic configurations demonstrate different physical and chemical properties. As a result, it is critical to synthesize carbon nanomaterials with controlled morphology and internal structures for their potential applications as building blocks for nanoscale electronics and photonics, catalyst supports for fuel cells, non-viral carriers for delivering biomolecules into cells, biomedical imaging, and additives for reinforced composite materials. In order to overcome these barriers, researchers need to investigate the interactions between catalysts and carbon nanomaterials to understand how the catalyst facilitate the growth of carbon nanomaterials and, thereby, obtain carbon nanomaterials with controlled properties through tailoring of their catalyst parameters.

A number of parameters are known to affect the synthesis of carbon nanomaterials, such as the composition and size of the catalysts, type of hydrocarbon gas, temperature, and reaction time. Different carbon nanomaterials having various carbon atomic configurations demonstrate different physical and chemical properties. As a result, it is critical to synthesize carbon nanomaterials with controlled morphology and internal structures for their potential applications as building blocks for nanoscale electronics and photonics, catalyst supports for fuel cells, non-viral carriers for delivering biomolecules into cells, biomedical imaging, and additives for reinforced composite materials. In order to overcome these barriers, researchers need to investigate the interactions between catalysts and carbon nanomaterials to understand how the catalyst facilitate the growth of carbon nanomaterials and, thereby, obtain carbon nanomaterials with controlled properties through tailoring of their catalyst parameters.

Dec 23rd, 2011

Implantable devices like pace makers or neurostimulators are powered by lithium batteries whose service life is as low as 10 years. Hence, many patients must undergo a major surgery to check the battery performance and replace the batteries as necessary. A team in Japan has now reported an interesting strategy that would keep using batteries but provides a mechanism for remotely recharging them from outside the body by converting laser light into thermal energy and subsequently to electricity. The main purpose of this study was to show that it is possible to remotely control electrical energy generation by laser light that can be transmitted through living tissue in order to target various bionic applications implanted in the body.

Implantable devices like pace makers or neurostimulators are powered by lithium batteries whose service life is as low as 10 years. Hence, many patients must undergo a major surgery to check the battery performance and replace the batteries as necessary. A team in Japan has now reported an interesting strategy that would keep using batteries but provides a mechanism for remotely recharging them from outside the body by converting laser light into thermal energy and subsequently to electricity. The main purpose of this study was to show that it is possible to remotely control electrical energy generation by laser light that can be transmitted through living tissue in order to target various bionic applications implanted in the body.

Dec 20th, 2011

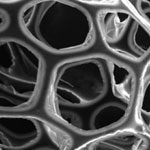

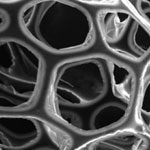

Ultra- or supercapacitors are emerging as a key enabling storage technology for use in fuel-efficient transport as well as in renewable energy. These devices combine the advantages of conventional capacitors - they can rapidly deliver high current densities on demand - and batteries - they can store a large amount of electrical energy. Supercapacitors offer a low-cost alternative source of energy to replace rechargeable batteries. Although the energy density of capacitors is quite low compared to batteries, their power density is much higher, allowing them to provide bursts of electric energy. Researchers have now fabricated novel high-performance sponge supercapacitors using a simple and scalable method. Their results shows that three-dimensional electrodes potentially have a huge advantage over conventional mixed electrode materials.

Ultra- or supercapacitors are emerging as a key enabling storage technology for use in fuel-efficient transport as well as in renewable energy. These devices combine the advantages of conventional capacitors - they can rapidly deliver high current densities on demand - and batteries - they can store a large amount of electrical energy. Supercapacitors offer a low-cost alternative source of energy to replace rechargeable batteries. Although the energy density of capacitors is quite low compared to batteries, their power density is much higher, allowing them to provide bursts of electric energy. Researchers have now fabricated novel high-performance sponge supercapacitors using a simple and scalable method. Their results shows that three-dimensional electrodes potentially have a huge advantage over conventional mixed electrode materials.

Dec 6th, 2011

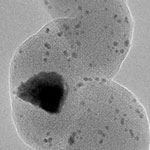

Using the CVD process, manufacturers can combine a metal catalyst such as iron with reaction gases such as hydrocarbon to form carbon nanotubes inside a high-temperature furnace. This process creates CNTs that are subsequently deposited in a collection environment and harvested into the desired end-product structural form. Understanding the processes in CVD growth of carbon nanotubes is important for their high yield and extended production. But even today, some 20 years since their discovery, the finer details of CNT growth mechanisms remain poorly understood. One of the issues that manufacturers have to grapple with is the levelling off and ultimate stoppage of CNT growth several minutes into the CVD process. This is referred to as catalyst poisoning - an inactivation or poisoning process of catalyst particles that has been attributed to an overcoat of amorphous carbon.

Using the CVD process, manufacturers can combine a metal catalyst such as iron with reaction gases such as hydrocarbon to form carbon nanotubes inside a high-temperature furnace. This process creates CNTs that are subsequently deposited in a collection environment and harvested into the desired end-product structural form. Understanding the processes in CVD growth of carbon nanotubes is important for their high yield and extended production. But even today, some 20 years since their discovery, the finer details of CNT growth mechanisms remain poorly understood. One of the issues that manufacturers have to grapple with is the levelling off and ultimate stoppage of CNT growth several minutes into the CVD process. This is referred to as catalyst poisoning - an inactivation or poisoning process of catalyst particles that has been attributed to an overcoat of amorphous carbon.

Oct 31st, 2011

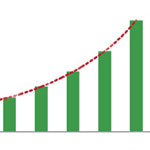

More than 100 companies around the world today are manufacturing carbon nanotubes and this number is expected to increase to more than 200 within the next five years, while there are more than 1,000 companies and institutions that are actively engaged in CNT research and development. This article looks at the market size, applications, processing technology and end-user products of carbon nanotubes. In addition, the study looks at industry leaders in the value chain, potential applications, products which are under development and are likely to enter the market in the next five to ten years. For this study, we have surveyed industry professionals/stakeholders in the CNTs value chain, extracted information from our proprietary in-house databases/ inter-linked databases as well as researched other primary and secondary sources and triangulated data and the findings are presented in this article.

More than 100 companies around the world today are manufacturing carbon nanotubes and this number is expected to increase to more than 200 within the next five years, while there are more than 1,000 companies and institutions that are actively engaged in CNT research and development. This article looks at the market size, applications, processing technology and end-user products of carbon nanotubes. In addition, the study looks at industry leaders in the value chain, potential applications, products which are under development and are likely to enter the market in the next five to ten years. For this study, we have surveyed industry professionals/stakeholders in the CNTs value chain, extracted information from our proprietary in-house databases/ inter-linked databases as well as researched other primary and secondary sources and triangulated data and the findings are presented in this article.

Oct 20th, 2011

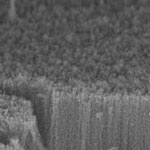

Vertical arrays of carbon nanotubes, called 'forests', are a common type of three-dimentional (3D) nanotube assembly that researchers work with in their labs. These forests can be produced by chemical vapor deposition technique and used for diverse applications such as in photo- or thermoacoustics, highly elastic conductive composites, for mechanical nanomanipulation, in catalysis, or as sensors in nanomedicine, just to name a few examples. These and other applications relay on connectivity of carbon nanotubes in the forest structure. New measurements show that room temperature electrical properties of this nanotube network reveal quite substantial nonlinerarities that became more pronounced at sample cooling.

Vertical arrays of carbon nanotubes, called 'forests', are a common type of three-dimentional (3D) nanotube assembly that researchers work with in their labs. These forests can be produced by chemical vapor deposition technique and used for diverse applications such as in photo- or thermoacoustics, highly elastic conductive composites, for mechanical nanomanipulation, in catalysis, or as sensors in nanomedicine, just to name a few examples. These and other applications relay on connectivity of carbon nanotubes in the forest structure. New measurements show that room temperature electrical properties of this nanotube network reveal quite substantial nonlinerarities that became more pronounced at sample cooling.

Oct 7th, 2011

Carbon nanotubes (CNTs) have not yet met commercial expectations from a decade ago, and now hot on its heels is graphene. Graphene is considered a hot candidate for applications such as computers, displays, photovoltaics, and flexible electronics. The biggest opportunity for both materials is in printed and potentially printed electronics. In a comparably short time a large amount of graphene materials have become commercially available contributing to further advancements and application development. At a fraction of the weight and cost of CNTs, graphene may displace carbon nanotubes and even indium tin oxide in some applications. Flexible, see-through displays may be the one application that finally puts graphene into the commercial spotlight.

Carbon nanotubes (CNTs) have not yet met commercial expectations from a decade ago, and now hot on its heels is graphene. Graphene is considered a hot candidate for applications such as computers, displays, photovoltaics, and flexible electronics. The biggest opportunity for both materials is in printed and potentially printed electronics. In a comparably short time a large amount of graphene materials have become commercially available contributing to further advancements and application development. At a fraction of the weight and cost of CNTs, graphene may displace carbon nanotubes and even indium tin oxide in some applications. Flexible, see-through displays may be the one application that finally puts graphene into the commercial spotlight.

Sep 28th, 2011

Heat has become one of the most critical issues in computer and semiconductor design. Three factors are playing the most important role in a microscale heat sink cooling system: the thermal conductivity of the material of the cooling fins; the heat exchange area of the cooling fins; and the convection between cooling fins and ambient. Carbon nanotubes satisfy the first two factors very well. They possess very high thermal conductivity and very high surface/volume ratio among other outstanding physical properties such as light, high current carrying capacity, excellent mechanical strength, etc. To reduce high temperatures, today's heat sinks are attached to the back of the chips to pull thermal energy away from the microprocessor and transfer it into the surrounding air. Researchers have now demonstrated the application of interface-enhanced CNTs as on-chip cooling fins in a microchannel heat sink.

Heat has become one of the most critical issues in computer and semiconductor design. Three factors are playing the most important role in a microscale heat sink cooling system: the thermal conductivity of the material of the cooling fins; the heat exchange area of the cooling fins; and the convection between cooling fins and ambient. Carbon nanotubes satisfy the first two factors very well. They possess very high thermal conductivity and very high surface/volume ratio among other outstanding physical properties such as light, high current carrying capacity, excellent mechanical strength, etc. To reduce high temperatures, today's heat sinks are attached to the back of the chips to pull thermal energy away from the microprocessor and transfer it into the surrounding air. Researchers have now demonstrated the application of interface-enhanced CNTs as on-chip cooling fins in a microchannel heat sink.

Subscribe to our Nanotechnology Spotlight feed

Subscribe to our Nanotechnology Spotlight feed