| Sep 04, 2024 | |

New liquid crystal coatings provide vibrant colors and fast production |

|

| (Nanowerk Spotlight) Color plays a crucial role in our daily lives, from the clothes we wear to the screens we gaze at. Yet, traditional methods of creating color, which rely on chemical pigments and dyes, face limitations—they fade over time, can be environmentally damaging, and offer limited visual effects. In recent years, scientists have sought alternative ways to produce color by mimicking nature's own palette. Structural color, a phenomenon where color is generated not by pigments but by microscopic structures that manipulate light, offers a more vibrant and sustainable approach. Found in the shimmering wings of butterflies and the iridescent feathers of peacocks, structural colors are not only bright and vivid but also resistant to fading. However, replicating these colors in a controlled, scalable, and economically viable way has proven to be a significant challenge. | |

| Despite the potential advantages, creating structural color coatings that are both visually striking and practical for widespread use has been a formidable task. The primary hurdle has been balancing the rapid production of these coatings with the need for uniform, bright colors. Traditional methods either produce dull, non-iridescent colors due to rapid self-assembly of the microscopic structures or require lengthy, controlled processes to achieve vibrant hues. These methods have limited the application of structural colors to niche uses, such as in high-end automotive finishes or specialized sensors, where cost and complexity are less of a concern. | |

| The emergence of liquid crystal technologies, particularly cholesteric liquid crystals, marked a turning point in this field. These materials naturally form helical structures that can reflect specific wavelengths of light, producing vivid, circularly polarized colors. Yet, even with cholesteric liquid crystals, achieving the necessary balance between production speed and optical quality has remained elusive. | |

| Recent advances in liquid crystal elastomers (LCEs), which combine the optical properties of liquid crystals with the mechanical flexibility of elastomers, have opened new avenues. LCEs maintain their structural integrity and coloration even under mechanical stress, making them ideal for applications requiring durability and dynamic visual effects, such as flexible displays or smart textiles. | |

| A recent study published in Advanced Functional Materials ("Cholesteric Liquid Crystal Elastomer Coatings with Brilliant Structural Colors and Mechanochromic Response Fabricated by Spray Deposition") by researchers in China has made significant strides in this area, introducing a new method to fabricate cholesteric liquid crystal elastomer (CLCE) coatings. The team's approach addresses many of the existing challenges, providing a way to rapidly produce coatings with bright, structural colors that can be scaled up for industrial applications. | |

|

|

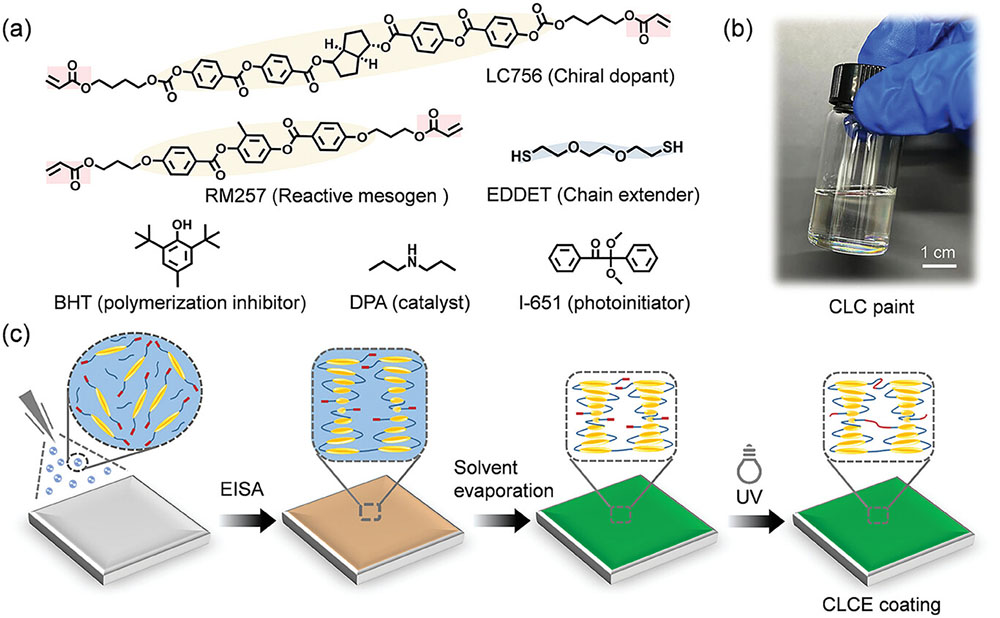

| a) Chemical compounds of the CLC paint. b) Photograph of the CLC paint with a transparent appearance. c) Schematic illustration of the preparation of CLCE coatings, including spraying of CLC paints on a substrate, formation of colored CLCE coatings through the EISA process, fully solvent evaporation, and UV irradiation to trigger the photo-crosslinking reaction. (Image: Reproduced with permission by Wiley-VCH Verlag) | |

| By utilizing a spray deposition technique followed by evaporation-induced self-assembly (EISA) and photocuring, they have developed CLCE coatings that exhibit not only brilliant structural colors but also a mechanochromic response—where the color changes in response to mechanical deformation. This novel approach represents a substantial improvement in both the speed of production and the quality of the resulting coatings. | |

| The innovation lies in the meticulous design of the CLCE paint and the process used to apply it. The researchers created a specialized paint mixture containing cholesteric liquid crystals along with various reactive components and solvents. When sprayed onto a surface, the solvent in the paint begins to evaporate, creating a Marangoni flow. This fluid movement, driven by variations in surface tension, aligns the liquid crystal molecules into the helical structures necessary for structural color. This self-assembly process takes just 60 seconds, a remarkably short time compared to previous methods. After the paint dries, it is cured with ultraviolet (UV) light, which solidifies the arrangement, locking in the molecular orientation and enhancing the durability of the coating. | |

| What makes this method particularly impactful is its ability to produce high reflectivity—up to 42%—in such a short time. Reflectivity, the measure of how much light a surface reflects, is a critical factor in the brightness and visibility of the color. | |

| The combination of rapid self-assembly and high reflectivity sets this technique apart from previous methods that either required much longer times or failed to achieve such vivid colors. The key to their success is in the precise control of the evaporation process and the carefully formulated composition of the paint, which includes a mix of reactive mesogens, chiral dopants, and other components that foster the formation of the desired helical structures. | |

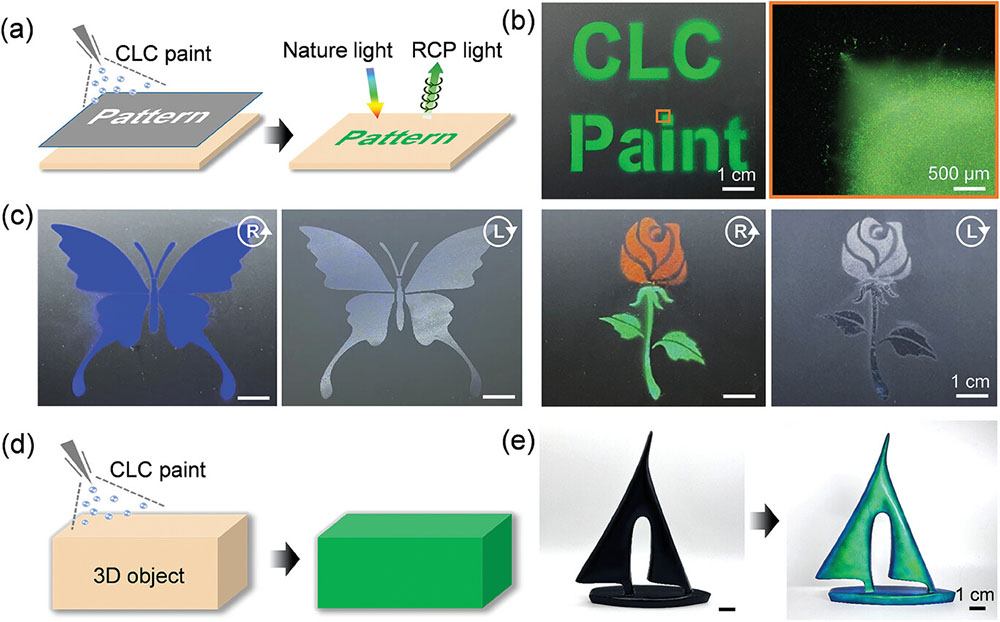

| To demonstrate the versatility and potential applications of their method, Li and colleagues conducted several proof-of-concept experiments. They showed that the CLCE coatings could be uniformly applied to both flat surfaces and complex three-dimensional objects, such as a model sailboat. This versatility suggests a wide range of potential applications, from aesthetic coatings for consumer products to advanced camouflage materials that can dynamically change color. Additionally, the team created intricate patterned coatings using masks to control where the paint was applied, resulting in complex designs with distinct colors. Such capabilities could be particularly useful in security printing or advanced display technologies. | |

|

|

| a) Scheme of spraying patterned CLCE coatings by masks. b) Photo of “CLC Paint” pattern and POM image of the point of letter “i.” c) The “butterfly” and “rose” patterns observed under a right-circular polarizer (RCP) and a left-circular polarizer (LCP). d) Scheme of spraying CLC paint on a 3D object. e) 3D sailboat model before and after spraying CLC paint. (Image: Reproduced with permission by Wiley-VCH Verlag) | |

| One of the most exciting aspects of these CLCE coatings is their mechanochromic property – the ability to change color when subjected to mechanical forces like stretching or compression. This is made possible by the unique molecular structure of cholesteric liquid crystals, which can alter their helical pitch, and thus their reflected color, in response to external stimuli. By spraying the coating onto an elastic substrate, like a silicone film, the researchers created materials that change color as they are stretched. This capability could be invaluable for developing wearable sensors or smart textiles that provide visual feedback on strain, pressure, or other mechanical changes. | |

| The researchers also explored additive color mixing with their coatings, layering different colors to create a broader palette. By spraying multiple layers of different colored CLCE paints, they successfully created a wide range of colors, expanding the potential applications for these coatings. This additive color mixing approach is particularly significant for creating customized colors for specific applications, from artistic and design uses to more technical applications in optics and displays. | |

| Scalability is another crucial advantage of this new method. The spray deposition technique used is compatible with existing industrial processes, making it feasible for large-scale production. The method's reliance on commercially available equipment and materials further lowers the barriers to adoption, suggesting that we could soon see these advanced coatings applied in a variety of settings, from consumer electronics to automotive finishes and beyond. | |

| The development of CLCE coatings with rapid self-assembly, high reflectivity, and mechanochromic response marks a notable advancement in the field of structural colors. By overcoming longstanding challenges related to production speed, scalability, and performance, this research paves the way for a wide array of new applications. The ability to produce these coatings efficiently and effectively could lead to their widespread use across multiple industries, including consumer goods, automotive, and wearable technology. | |

| This study highlights the importance of continuous innovation in materials science, particularly in the realms of liquid crystals and elastomers. As techniques are refined and new material combinations are explored, the potential applications for structural color coatings are likely to grow even further, ushering in an era where color is not just a visual experience but a dynamic and interactive one. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|