| Aug 27, 2024 | |

Flexible quantum dot displays achieve ultra-high resolution and bending stability |

|

| (Nanowerk Spotlight) Flexible displays represent a promising technology for enhancing virtual and augmented reality (VR/AR) experiences by providing immersive digital worlds and information-rich overlays on our physical environment. Despite rapid advances in computing power, graphics, and software, one crucial component has consistently lagged: the displays that bring these virtual visions to our eyes. The limitations of current screen technology – such as insufficient resolution, lack of flexibility, and suboptimal visual experiences – have slowed the widespread adoption of VR and AR, limiting their applications mainly to niche markets and tech enthusiasts. | |

| These challenges arise from a fundamental mismatch between the capabilities of traditional flat, rigid displays and the complexities of human vision. Human eyes have curved retinas that can perceive incredibly fine details across a wide field of view. Replicating this in a wearable device requires displays that can conform to the shape of the eye while delivering pixel densities far beyond those found in today's smartphones or televisions. | |

| To address these challenges, researchers have been exploring novel materials and fabrication techniques. Quantum dots – nanoscale semiconductor particles that emit light when electrically stimulated – have emerged as a promising technology due to their vibrant colors and potential compatibility with flexible substrates. However, developing ultra-high-resolution quantum dot displays that also maintain durability under repeated bending has proven difficult, with previous attempts often failing to achieve both high image quality and mechanical stability. | |

| In a recent breakthrough, researchers have successfully developed flexible ultra-high-resolution quantum dot light-emitting diodes (FUR-QLEDs) that deliver both exceptional image quality and mechanical durability. As reported in Advanced Functional Materials ("Flexible Ultrahigh-Resolution Quantum-Dot Light-Emitting Diodes"), these devices achieved a resolution of 9,072 pixels per inch, which significantly surpasses the capabilities of current commercial displays. | |

|

|

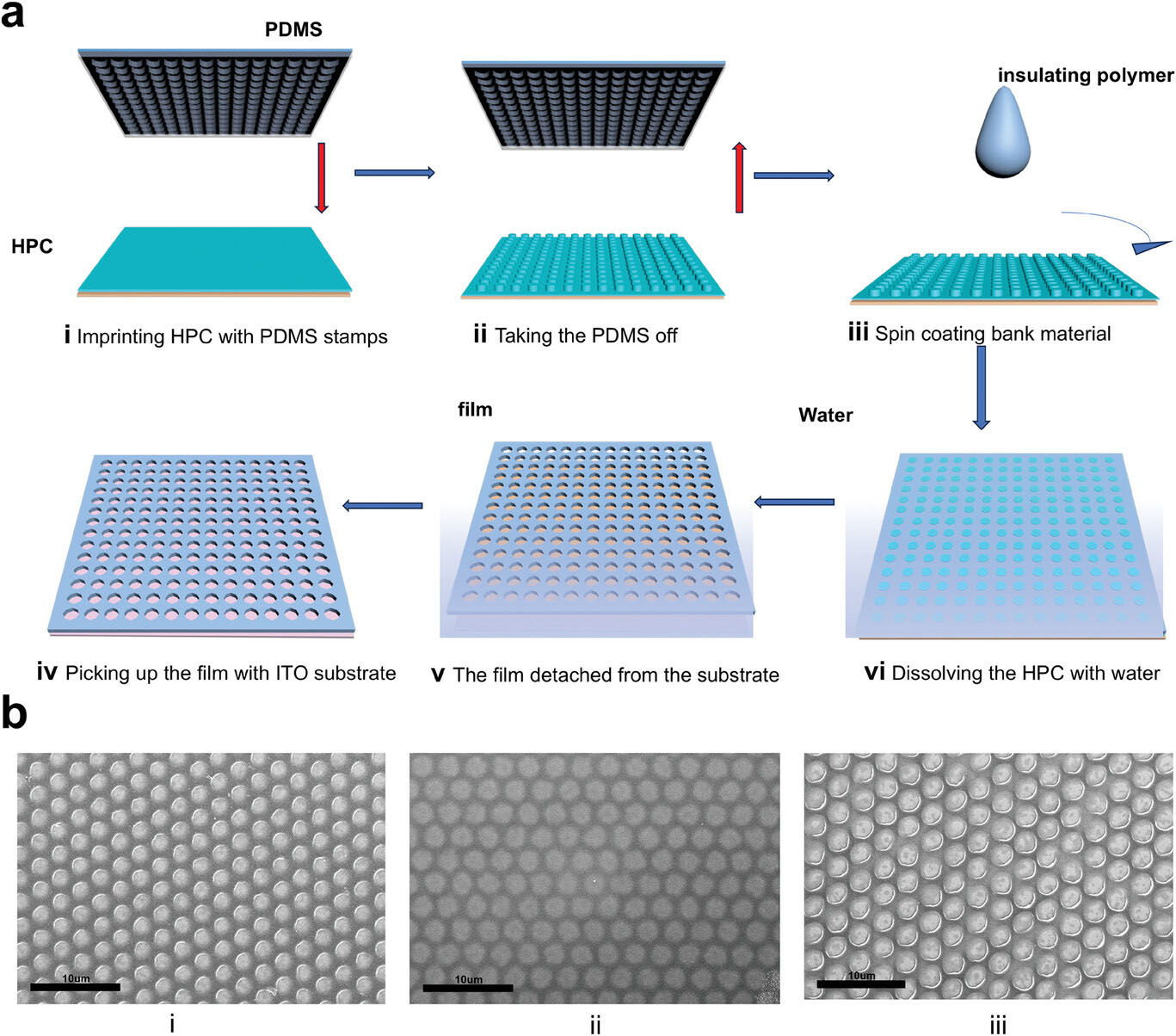

| Fabrication of patterned insulation films by nanoimprint. a) Schematic illustrating the preparation process of patterned PMMA films. b) SEM images of patterned films fabricated using different materials: (i) PMMA alone, (ii) PMMA (1:1) blend, (iii) PS. (Image: Reproduced with permission by Wiley-VCH Verlag) | |

| The team, led by scientists at Fuzhou University in China, utilized a combination of nanoimprinting and surface modification techniques to fabricate these devices. By using nanoimprint lithography, they created patterned insulating films that allowed precise control of pixel size and spacing at the micrometer scale. By optimizing the materials and processes, they were able to achieve uniform, defect-free pixel arrays over large areas on flexible substrates. | |

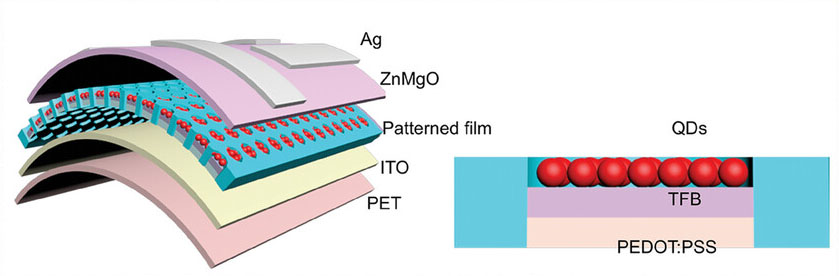

| A notable innovation involved modifying the hole injection layer, composed of the conductive polymer PEDOT, to enhance its compatibility with the patterned substrate. By adding a small amount of isopropyl alcohol to the PEDOT solution, the researchers improved its wettability and electrical conductivity. This adjustment enabled the formation of high-quality functional layers within the pixel microholes of the patterned film, contributing to the display's exceptional performance. | |

| The FUR-QLED devices demonstrated impressive performance metrics. In addition to the ultra-high resolution of 9,072 pixels per inch, they achieved a maximum external quantum efficiency (EQE) of 15.7% and a peak brightness of 15,163 candelas per square meter. These figures are among the highest reported for flexible QLED displays with resolutions exceeding 1,000 pixels per inch. | |

| Beyond the impressive visual specifications, the researchers also focused on optimizing the mechanical properties of their flexible displays. They conducted extensive bending tests, subjecting the devices to multiple flexing cycles at various curvature radii. These tests revealed that the elastic modulus of the patterned insulating film is crucial for determining the bending stability of the overall device. | |

| When the elastic modulus of the patterned film was much higher than that of the functional layers (the light-emitting quantum dot layer and charge transport layers), it induced excessive stress during bending. This stress led to degradation of the functional layers, causing increased surface roughness, delamination between layers, and ultimately reduced device performance. | |

| To mitigate this issue, the researchers adjusted the composition of the patterned film to better match the elastic modulus of the functional layers. By doping the polymer PMMA with polyethylene oxide or using polystyrene, they reduced the elastic modulus mismatch, which significantly improved device durability. | |

|

|

| Schematic of FUR-QLED devices. (Image: Reproduced with permission by Wiley-VCH Verlag) | |

| Optimized FUR-QLEDs maintained 91% of their initial brightness even after 400 bending cycles, demonstrating remarkable durability for such high-resolution flexible displays. The researchers provided detailed analyses of the underlying mechanics and degradation mechanisms, which offer valuable insights for future development of durable flexible electronics. | |

| The significance of this work extends beyond the impressive technical specifications. By demonstrating ultra-high resolution, high efficiency, and mechanical durability in a single flexible display, the researchers have addressed several key challenges that have previously limited the development of advanced near-eye displays for VR and AR. | |

| The ability to conform displays to the curvature of the human eye while maintaining high image quality could enhance the comfort and immersiveness of VR/AR experiences. The high pixel density achieved in these displays could potentially reduce the "screen door effect," where gaps between pixels become visible and disrupt the illusion of a seamless virtual world. | |

| Furthermore, the insights gained regarding the impact of material properties on bending stability provide a valuable foundation for future developments in flexible electronics. As noted in the study, the fabrication methods employed offer advantages in terms of simplicity, ease of operation, and reproducibility – factors that could facilitate potential commercialization and scaling of the technology. | |

| While further refinement and testing are necessary to bring these displays to market, this work represents a significant step toward achieving lifelike, adaptive near-eye displays. As VR and AR technologies continue to evolve and find applications beyond gaming and entertainment, advancements in display technology, such as those demonstrated here, will be essential for improving our interactions with digital content and environments. | |

| The researchers contextualize their findings within the emerging concept of the Metaverse – a network of interconnected virtual spaces that some view as the next evolution of the internet. While the exact form and adoption of the Metaverse remain to be seen, it's evident that advancements in display technology will be critical for creating convincing and comfortable virtual experiences. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|