| Aug 26, 2024 | |

3D-printed microstructures for precise, pump-free liquid flow in microfluidic systems |

|

| (Nanowerk Spotlight) The control of fluids at microscopic scales is fundamental to numerous technologies, from medical diagnostics to water purification. Traditionally, moving small volumes of liquid has relied on mechanical pumps or electrical fields, methods that add complexity, consume energy, and can interfere with sensitive samples. These limitations have long constrained the development of more efficient and versatile microfluidic systems. | |

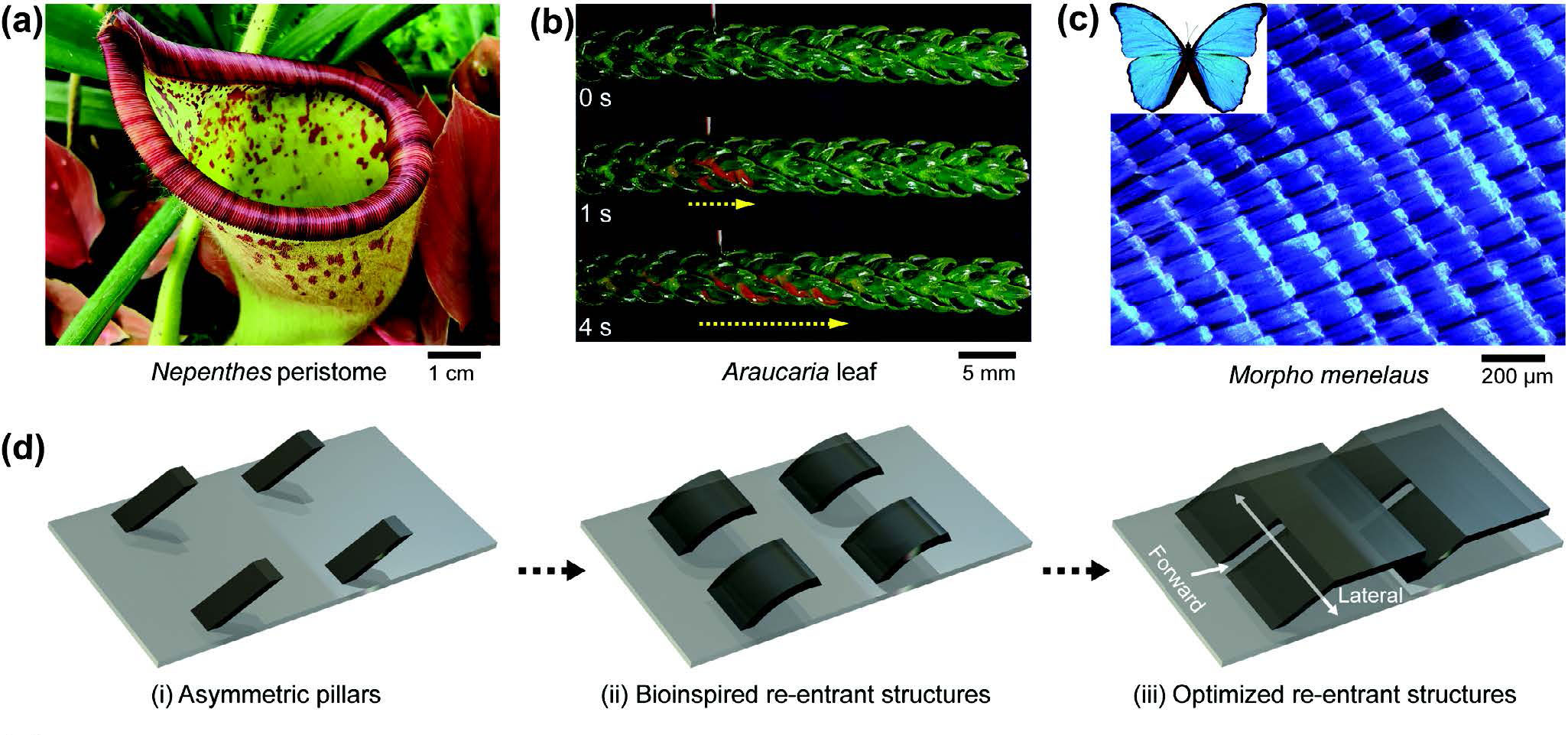

| Nature, however, demonstrates elegant solutions to fluid manipulation. The carnivorous pitcher plant uses microscopic grooves on its leaves to guide insects towards its trap, while certain desert beetles harvest water from fog using specialized surface structures. These examples showcase how precisely engineered surfaces can control liquid movement without external energy input, inspiring researchers to develop artificial systems with similar capabilities. | |

| Early attempts to mimic these natural mechanisms faced significant challenges. Conventional fabrication techniques struggled to recreate the intricate surface geometries responsible for directional fluid transport. As a result, most synthetic structures could only move liquids over distances of a few centimeters and lacked precise control over flow direction and speed. These shortcomings severely limited the practical applications of bio-inspired microfluidic devices. | |

| Despite these hurdles, the field of microfluidics has advanced steadily. Improvements in microfabrication, particularly soft lithography, enabled the creation of more complex channel geometries. Concurrently, progress in surface chemistry allowed finer control over wetting properties. While these developments incrementally improved passive fluid control, a significant performance gap remained between artificial systems and their natural counterparts. | |

| The recent maturation of high-resolution 3D printing technologies has dramatically altered this landscape. Techniques such as two-photon polymerization and digital light processing now allow the fabrication of microscale structures with unprecedented complexity and precision. This capability has opened new avenues for engineering surfaces with liquid transport properties that can meet or exceed those found in nature. | |

| Against this backdrop, a collaborative team from Southeast University in China and Nanyang Technological University in Singapore has achieved a breakthrough in passive liquid control. Their work, published in the journal Advanced Materials ("Bioinspired Capillary Transistors"), introduces a microfluidic system that demonstrates unparalleled control over liquid movement without external energy input. | |

|

|

| Design and fabrication of asymmetric re-entrant structures with long overhangs and connected microchannels for unidirectionalmicrofluidics. a) The pitcher of Nepenthes alata. b) Unidirectional transport of ethanol (infusing rate = 3.0 mL h−1) on Araucaria leaf with ratchet structures. c) Reentrant scales on the wing of Morpho menelaus. d) Design of different structures for unidirectional liquid transport: (i) asymmetric pillars, (ii) bioinspired re-entrant structures, and (iii) asymmetric re-entrant structures with long overhangs and microchannels. (Image: Adapted from DOI:10.1002/adma.202310797 with permission by Wiley-VCH Verlag) | |

| The researchers used digital light processing, an advanced 3D printing method, to fabricate arrays of tiny structures called "re-entrant" geometries. Each less than half a millimeter wide, these structures feature complex shapes with overhanging elements that create asymmetric surface properties. By carefully optimizing this geometry, the team maximized the difference in surface tension forces between the front and back of each structure, creating a strong driving force that pulls liquid in one direction while preventing backflow. | |

| The optimized design achieved remarkable improvements in passive liquid transport, pulling water vertically to a height of 102.3 mm – more than three times higher than previous synthetic systems. For ethanol, the structures achieved heights of 44.6 mm. Importantly, this liquid transport occurred spontaneously without any external energy input, with the microstructures essentially acting as a pump powered solely by surface tension. | |

| This advancement could revolutionize the design of sustainable and cost-effective microfluidic devices across multiple fields. In medical diagnostics, for instance, these structures could enable more sensitive and portable lab-on-a-chip devices, providing rapid, point-of-care testing in resource-limited settings by precisely controlling the movement of biological samples and reagents without pumps or electricity. | |

| In water purification, the ability to transport liquids over longer distances without energy input could enhance the efficiency of solar stills or enable new passive filtration systems. In electronics cooling, these structures could improve heat dissipation by optimizing the transport of cooling fluids without the need for pumps. | |

| Moreover, the researchers demonstrated more complex fluid manipulation capabilities. By varying the geometry of the structures, they created one-way valves and even split or combined liquid streams. This fine-grained control over fluid behavior opens up possibilities for creating sophisticated "labs-on-a-chip" for applications like chemical synthesis or biological assays. | |

| Perhaps most intriguingly, the team proposes the concept of "capillary transistors"—analogous to electronic transistors—that can switch and amplify liquid flows. Just as electronic transistors enabled complex integrated circuits, these fluidic transistors could pave the way for intricate microfluidic networks for advanced analytical or manufacturing processes. | |

| While the current work focused on water and ethanol, extending this approach to a wider range of liquids presents challenges. The structures currently work best with low-viscosity liquids, and adapting the design for more viscous fluids like blood or oil will require further optimization. The researchers suggest that tuning the surface chemistry could address some of these issues, but more research is needed to confirm this. | |

| Despite these challenges, this work represents a significant advance in our ability to passively control fluid flows at the microscale. As the technology is refined and adapted to different applications, it has the potential to enable new classes of energy-efficient microfluidic devices. Realizing this potential will require addressing the technical challenges and demonstrating reliable performance under varied conditions, but the prospects are promising. | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|