| Aug 23, 2024 |

Turning wastewater into valuable proteins

|

|

(Nanowerk News) The growing world population means that the environment is under great strain. Agriculture takes up large land areas and discharges nutrients to the surrounding environment. At the same time, there is tremendous pressure on the aquatic environment from all forms of industrial production that emits residual products such as wastewater, and regardless of whether we are talking about agricultural operations or industry, it is today associated with a huge energy consumption and the resulting climate impact.

|

|

With a new research breakthrough, researchers from DTU have succeeded in tackling all these problems in their search for the food of the future. Using the yeast cell Debaryomyces hansenii (D. hansenii), the researchers have shown that it is possible to exploit some of the industry’s problematic waste streams to produce proteins at very low cost and very low energy consumption. This could move food production away from the fields and into steel tanks, the environment is spared from the wastewater, and the climate is far less impacted by CO2.

|

|

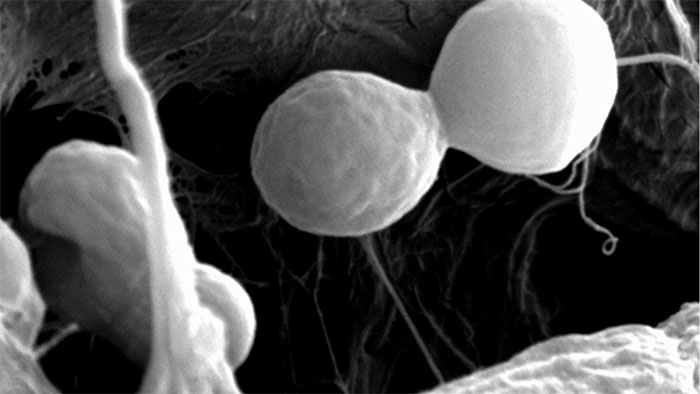

| Electron microscopy image of the yeast cell D. hansenii, a robust cell that thrives in highly saline environments. (Image: Jose Ramos)

|

Salt-tolerant yeast

|

|

For many years, Associate Professor José Martinez from DTU Bioengineering has researched yeast cells that in nature are adapted to extreme conditions such as high temperatures, low nutrient content, or high salinity. D. hansenii is adapted to aquatic environments with high salinity and thrives in water up to six times as salty as normal seawater. That gave the associate professor an idea.

|

|

“There are businesses that create waste streams that are rich in nutrients, but also have a very high salt content, which is often a problem. The salinity prevents utilization of the nutrients while preventing businesses from discharging their waste streams as ordinary wastewater, which means they have to special treat, and this is costly. Why don’t we try to grow this type of yeast in these salty waste streams?, he asked himself.

|

Sugar and nitrogen

|

|

José and his research team therefore contacted Arla Foods and agreed to test D. hansenii in a highly salty residue from cheese production - a residue that was also rich in the sugar lactose. The experiment all expectations. The yeast cells easily metabolized the sugars from this waste stream, and the higher the salt content, the more efficient the growth. However, the yeast growth was not quite as efficient as it could be. There was simply too little nitrogen present.

|

|

Manuel Quirós works as a specialist at Novo Nordisk and, like José Martinez, has researched the yeast type D. hansenii. During a coffee meeting, the two biologists discussed the limitations of the DTU researcher’s results with the lactose-rich waste stream. Manuel Quirós said that Novo Nordisk ends up with a salty residue that is high in nitrogen in connection with the manufacture of haemophiliacs, and thought that it might be useful. And it quickly developed from a coffee talk to an experimental setup.

|

|

“We simply mixed the two saline waste streams - the one with a high lactose content and the one with a high nitrogen content. We used them as they were. We didn’t need to add fresh water, nor did we need to sterilize the fermentation tank, because the salt prevented the growth of other microorganisms. It was plug and play,” as the associate professor puts it.

|

|

D. hansenii thrived in this salty mixture. But if it was to be of more than research interest, then the yeast would also have to produce a commercially interesting product, and with the help of the gene technology CRISPR, José Martinez’s research team modified D. hansenii to form a protein as it grew.

|

|

| Fermentation can be used to produce vitamins, proteins, food ingredients such as dyes and flavors, medicines and vaccines. (Image: DTU)

|

New way of thinking

|

|

The CRISPR technology enables researchers to modify the yeast cell so it can produce many different proteins and other substances. Initially, they settled on a fluorescent protein that was to be used as a model substance. In this way, they could easily get a production target by measuring how strongly fluorescent the liquid was when the yeast cells had been at work.

|

|

The researchers tested several mixtures of the waste streams from Arla Foods and Novo Nordisk, and the optimal mixture had a salinity of about twice that of seawater and a sugar content of about 12 grams per litre.

|

|

Using the yeast type D. hansenii is nothing new. It has been the subject of intense research for several decades. But research has previously focused on finding the gene in the yeast cells that makes them salt-tolerant, and then try to transfer this gene to plants so that they can better tolerate high salinity. However, it has turned out to be extremely complex, because salt tolerance seems to be linked to several genes that work together.

|

|

What José Martinez and his research colleagues have done is to use the yeast cells themselves and their salt-tolerant properties and then modify them to produce something ourselves, which we can then exploit. Although it sounds simple, it took two years of intense research for José Martinez and his research colleagues to achieve a breakthrough.

|

Commercial products

|

|

With the CRISPR technology, the door has been opened for a wide range of products based on D. hansenii and the industry’s waste products. José Martinez sees great opportunities in, e.g., milk substitutes, artificial meat, various protein-based pigments, and enzymes. But you can also use the yeast cells themselves without producing either proteins or enzymes. The yeast biomass itself can be used in feed for calves and other animal husbandry, and then the yeast can be used to process meat, so that a much more efficient maturation is achieved.

|

|

However, it is not only in food that José Martinez sees great opportunities. José is currently involved in a research partnership to develop sustainable fuels. Here, José Martinez and his research team plan to modify D. hansenii to produce lipids - fats - that can easily be converted into a green fuel.

|

|

The sustainable element of the research is important for Novo Nordisk’s commitment to the project.

|

|

“Novo Nordisk wants to take full responsibility for our entire value chain. Our strategy is called Circular for Zero. We have three focus areas: reducing the use of resources, reducing CO2 emissions, and minimizing waste streams,” explains Manuel Quirós.

|

Upscaling

|

|

Although the research results with the yeast cell D. hansenii are very promising, there is a long way to go before commercial exploitation. So far, the DTU researchers have only worked on a laboratory scale, where one to five litres of waste streams with added yeast cells have been tested.

|

|

The next step in the scale-up is 10-30 litres, and already here José Martinez predicts that there will be challenges with an efficient oxygen supply to the entire volume of liquid. The step up to the several thousand litres that will be involved in a commercial production will present other unknown challenges, so it will probably take at least 10 years before we see full-scale yeast tanks with D. hansenii.

|

|

But the DTU researcher is absolutely sure that this research breakthrough is an important step in the green transition.

|