| Sep 14, 2024 |

First flexible perovskite solar cells on polycarbonate films

(Nanowerk News) Perovskite photovoltaic devices have garnered much attention from both the academic and industrial R&D world because they combine high power conversion efficiencies and low-cost manufacturing processes since they can be deposited in ink form or through simple evaporation. This feature makes perovskite solar cells an ideal choice for fabrication and integration with ultrathin and lightweight novel substrate materials, enabling one to meet the demands of the emerging market of flexible electronics and find applications that cannot be achieved with conventional photovoltaic devices including smart buildings, wearable and portable electronic devices, and self-powered internet of things.

|

|

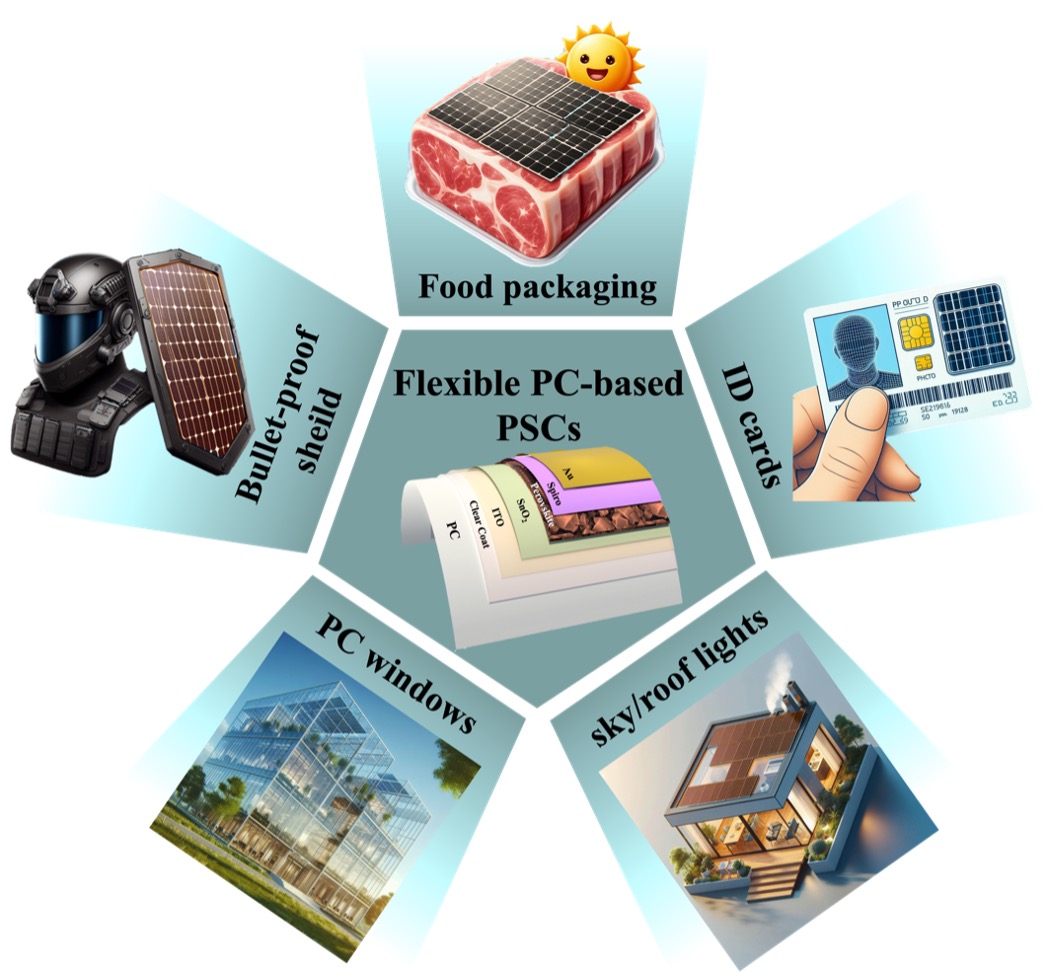

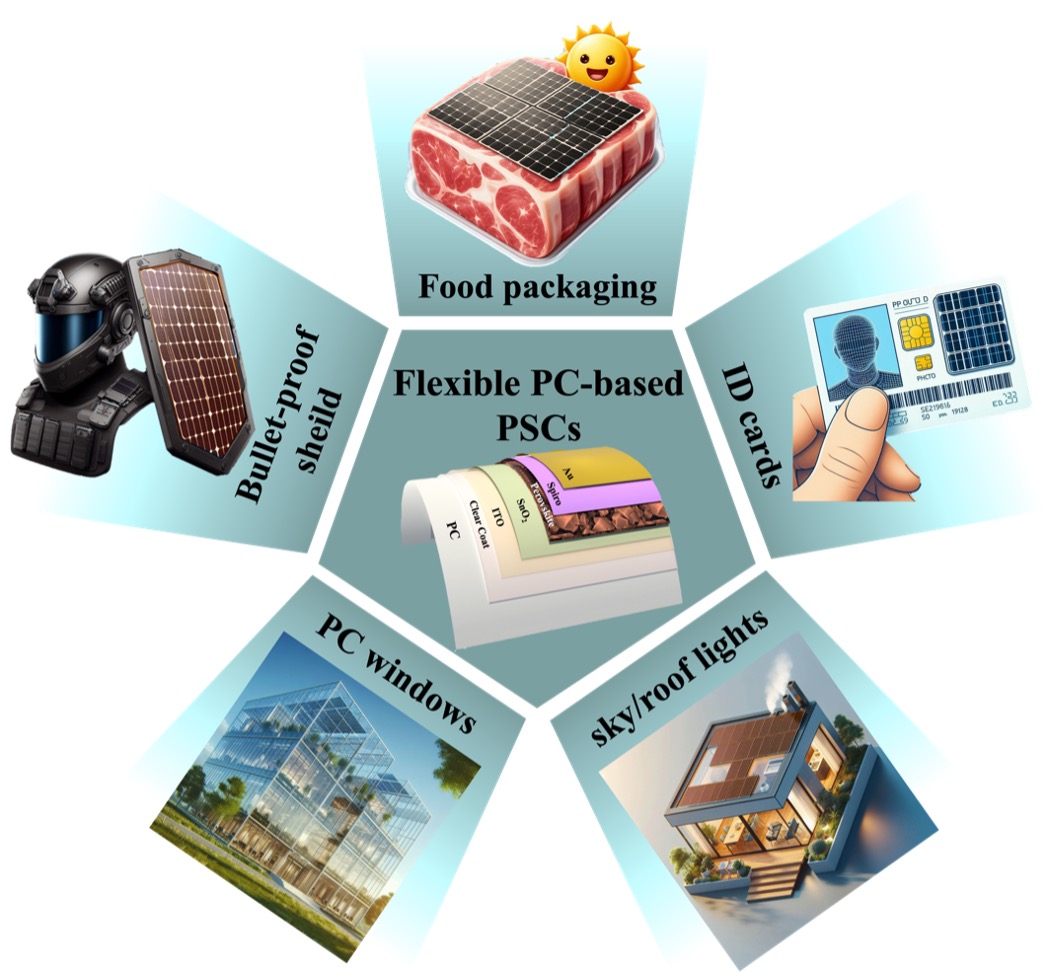

| The first-ever perovskite solar cells on polycarbonate films via novel planarization, reducing surface roughness and boosting chemical and moisture resistance. Flexible devices deliver 13.0% efficiency, with satisfactory flexibility and stability in air. This innovation can enable future solar power integration in ID cards, smart packaging, and beyond, representing a significant step forward in smart photovoltaic technology. (Image: ©Wiley-VCH Verlag)

|

|

The market for polycarbonate includes a wide range of applications such as glazing and greenhouses in buildings, automotive uses, bulletproof windows, shields, protective eyewear, food packaging, medical devices, plastic lenses for eyewear, optical media, electronics, and electronic IDs (e-IDs), passports, and smart cards. It is valued at $20.6 billion USD in 2024, with $1.7 billion in the films sector.

|

|

Comparatively, polyethylene terephthalate (PET), which is the most common film substrate for perovskite solar cells, boasts a larger market at $26.99 billion. Polyethylene naphthalate (PEN), another common film substrate for the purpose, lags behind at $1.74 billion with its growth hindered by high costs and lower technological maturity. In small quantity sheet pricing, polycarbonate ($194.62) falls between PET ($147.57) and PEN ($203.80), while offering higher flexibility, transparency and thermal tolerance, highlighting its potential as a competitive substrate option.

|

|

Despite its widespread use, polycarbonate has not been used as a substrate for perovskite solar cells up to now due to its poor chemical resistance to organic solvents and high surface roughness. These properties have made it challenging to fabricate the very thin layers (100s of nanometers) of perovskite devices that are cast from organic solvents.

|

|

An international collaborative effort from various institutions, the Centre for Hybrid and Organic Solar Energy (CHOSE), Department of Electronic Engineering at Tor Vergata University of Rome, Italy, the ENEA Frascati Research Centre, Italy, the Department R2R-Technologies at the Fraunhofer FEP, Germany, the Department of Textile Engineering and Chemical Engineering at the University of Guilan, Iran, Halocell Europe, Italy, and Institute of Structure of Matter ISM-CNR, Italy, has resulted in the development of the first-ever perovskite solar cells on polycarbonate films.

|

|

The challenges of roughness and resistance to solvents were solved by developing a new planarizing layer over the polycarbonate films applied in liquid form using blade coating. This innovation reduced surface roughness from 1.46 µm to 23 nm, cut the water vapor transmission rate in half, and improved solvent resistance. As a result, they achieved a power conversion efficiency of 13.0% for solar cells on polycarbonate substrates, with good durability and flexibility.

|

|

| Photograph of right) neat polycarbonate film and left) and four flexible perovskite solar cells fabricated on polycarbonate film. (Image: ©Wiley-VCH Verlag)

|

|

The research findings have recently been published in Advanced Energy Materials ("Flexible Perovskite Solar Cells on Polycarbonate Film Substrates"), highlighting the potential of these flexible perovskite solar cells for integration in the huge market of everyday products made from polycarbonate. With all layers, except the two electrodes, solution-processed at low temperatures (maximum 100 °C), the technology is compatible with low-cost manufacturing and easy integration with other printed electronic components.

|

|

The new solution for planarization and solvent barrier can also be used for other types of optoelectronic devices (LEDs, transistors etc.) and substrates. Opening up the market of flexible solar cells to new substrate materials can play a significant role in the future for energy harvesting, powering future electronic devices, and contributing to rapidly growing markets like smart windows, skylights, buildings, smart digital cards, product packaging, wearables, Internet of Things electronics.

|