X-Ray Tomography: Unveiling the Internal Structure of Materials

What is X-ray Tomography?

X-ray computed tomography (CT), also known as X-ray tomography, is a powerful non-destructive imaging technique that allows researchers to visualize and analyze the internal structure of materials in three dimensions. It combines the principles of X-ray imaging and computed tomography to create detailed cross-sectional images, or "slices," of an object. By stacking these slices together, a complete 3D reconstruction of the object's interior can be obtained.

Key Components of X-ray Tomography

An X-ray tomography system consists of several essential components:

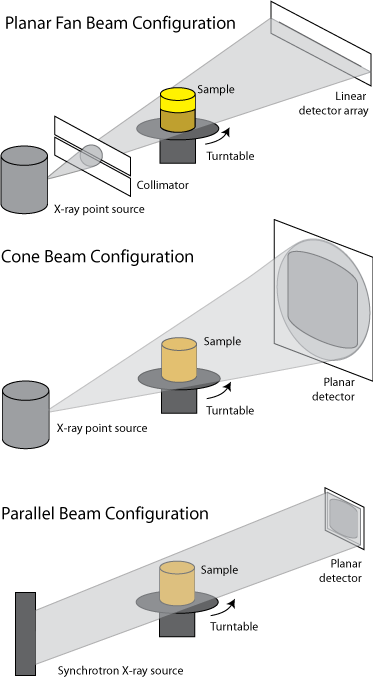

- X-ray Source: The X-ray source generates a beam of X-rays that penetrates the sample. The X-rays can be produced by a laboratory-based source, such as an X-ray tube, or by a synchrotron facility, which provides high-intensity, monochromatic X-rays.

- Sample Stage: The sample is placed on a stage that can rotate and/or translate, allowing the acquisition of projection images from different angles. The stage is designed to hold the sample securely and minimize any movements during the scanning process.

- X-ray Detector: The detector captures the X-rays that have passed through the sample, converting them into digital signals. Common detectors used in X-ray tomography include scintillator-based detectors, which convert X-rays into visible light, and direct detection systems, such as flat panel detectors or charge-coupled devices (CCDs).

- Data Acquisition and Reconstruction Software: Specialized software controls the data acquisition process, synchronizing the X-ray source, sample stage, and detector. The software also performs the mathematical reconstruction of the projection images into cross-sectional slices and 3D volumes using algorithms such as filtered back projection or iterative reconstruction methods.

Advantages of X-ray Tomography

X-ray tomography offers several key advantages over other imaging techniques:

- Non-destructive Analysis: X-ray tomography allows the internal structure of materials to be studied without the need for sectioning or destructive sample preparation. This is particularly valuable for rare, fragile, or irreplaceable samples.

- High Resolution: With advancements in X-ray sources and detectors, X-ray tomography can achieve spatial resolutions down to the sub-micrometer scale. This enables the visualization of fine details and internal features that may not be accessible through other techniques.

- Three-dimensional Imaging: X-ray tomography provides a complete 3D representation of the sample's internal structure. This allows researchers to study the spatial relationships between different components, analyze pore networks, and quantify morphological parameters such as volume, surface area, and connectivity.

- Multiscale Imaging: X-ray tomography can be performed at various length scales, from the nanoscale (nano-CT) to the macroscale (medical CT). This multiscale capability enables the investigation of hierarchical structures and the linking of material properties across different length scales.

Applications of X-ray Tomography in Nanotechnology

X-ray tomography has found numerous applications in nanotechnology research and development:

Nanomaterials Characterization

X-ray tomography is used to characterize the internal structure and morphology of nanomaterials, such as nanoparticles, nanofibers, and nanocomposites. It can reveal the size, shape, and spatial distribution of nanostructures, as well as the presence of defects or inhomogeneities.

Porous Materials Analysis

X-ray tomography is particularly useful for studying porous materials, such as zeolites, metal-organic frameworks (MOFs), and nanocatalysts. It can provide quantitative information on pore size distribution, pore connectivity, and tortuosity, which are critical factors in determining the performance of these materials in applications like catalysis, gas storage, and separation.

In-situ and Operando Studies

X-ray tomography can be combined with in situ and operando techniques to study the dynamic behavior of nanomaterials under realistic operating conditions. For example, it can be used to monitor the structural changes in battery electrodes during charging and discharging cycles, or to investigate the evolution of catalyst nanoparticles during chemical reactions.

Biological and Biomedical Applications

X-ray tomography is widely used in biological and biomedical research to study the internal structure of tissues, organs, and biomaterials at the micro- and nanoscale. It can provide insights into the organization of cells, the distribution of nanoparticles in drug delivery systems, and the integration of implants with surrounding tissues.

Challenges and Future Perspectives

Despite its numerous advantages, X-ray tomography also faces some challenges. One of the main limitations is the trade-off between resolution and sample size. Achieving high spatial resolution often requires the use of smaller samples or more focused X-ray beams, which can limit the field of view and the representativeness of the analyzed volume.

Another challenge is the management and analysis of the large datasets generated by X-ray tomography. The 3D reconstruction and segmentation of complex structures require advanced computational tools and algorithms, as well as efficient data storage and processing infrastructure.

Future developments in X-ray tomography will focus on further improving spatial and temporal resolution, enhancing the sensitivity to low-contrast features, and integrating complementary imaging modalities, such as spectroscopic or phase-contrast techniques. The combination of X-ray tomography with other characterization methods, such as electron microscopy or atom probe tomography, will provide a more comprehensive understanding of nanomaterials across multiple length scales.

The application of machine learning and artificial intelligence algorithms to X-ray tomography data analysis is also expected to grow, enabling faster and more accurate segmentation, classification, and quantification of complex 3D structures.

Further Reading

International Materials Reviews, Quantitative X-ray tomography

Nature Reviews Methods Primers, X-ray computed tomography