Transparent Electronics: The Future of Invisible Circuits

What are Transparent Electronics?

Transparent electronics refer to the emerging field of developing electronic devices and circuits that are virtually invisible to the human eye. By using transparent materials such as conductive oxides, polymers, and nanomaterials, researchers aim to create electronic components that can be seamlessly integrated into displays, windows, and other surfaces without obstructing visibility.

Key Materials in Transparent Electronics

Several materials play a crucial role in enabling transparent electronics:

Transparent Conductive Oxides (TCOs)

TCOs are materials that combine high electrical conductivity with optical transparency. The most widely used TCO is indium tin oxide (ITO), which is extensively employed in touch screens, solar cells, and displays. Other TCOs include fluorine-doped tin oxide (FTO) and aluminum-doped zinc oxide (AZO). These materials are deposited as thin films on transparent substrates to create conductive electrodes and interconnects.

Graphene

Graphene, a two-dimensional form of carbon, has emerged as a promising material for transparent electronics due to its exceptional electrical conductivity, mechanical strength, and optical transparency. Graphene can be synthesized through various methods, such as chemical vapor deposition (CVD) or exfoliation, and can be transferred onto transparent substrates to create flexible and transparent electrodes.

Conductive Polymers

Conductive polymers, such as poly(3,4-ethylenedioxythiophene) polystyrene sulfonate (PEDOT:PSS) and polyaniline (PANI), offer an alternative to inorganic materials for transparent electronics. These polymers can be processed from solution, enabling low-cost and large-area fabrication techniques like spin coating and inkjet printing. Conductive polymers exhibit high transparency, flexibility, and tunable electrical properties.

Fabrication Techniques

Transparent electronics require specialized fabrication techniques to maintain the optical transparency of the devices. Some common fabrication methods include:

Thin Film Deposition

Thin film deposition techniques, such as sputtering, thermal evaporation, and atomic layer deposition (ALD), are used to deposit transparent conductive materials onto substrates. These methods allow for precise control over the thickness and uniformity of the films, enabling the creation of high-quality transparent electrodes and active layers.

Solution Processing

Solution processing techniques, such as spin coating, dip coating, and inkjet printing, are particularly suitable for depositing conductive polymers and nanomaterials. These methods offer the advantages of low-cost, large-area fabrication and compatibility with flexible substrates. Solution processing enables the creation of transparent electronic devices on various surfaces, including plastic, paper, and textiles.

Nanopatterning

Nanopatterning techniques, such as nanoimprint lithography and self-assembly, are employed to create nanostructured transparent electrodes and active layers. By patterning materials at the nanoscale, researchers can enhance the optical and electrical properties of transparent electronic devices. Nanopatterning also enables the fabrication of high-resolution features and the integration of multiple functionalities into a single device.

Applications of Transparent Electronics

Transparent electronics find applications in various areas, including:

Displays

Transparent displays are a key application of transparent electronics. By using transparent electrodes and active materials, researchers can create displays that can be integrated into windows, windshields, or eyewear. These displays can provide information, entertainment, or augmented reality experiences without obstructing the user's view.

Solar Cells

Transparent solar cells can be incorporated into windows and building facades to generate clean energy while maintaining optical clarity. By using transparent conductive materials and semi-transparent active layers, researchers can develop solar cells that harvest light while allowing a portion of it to pass through, creating energy-generating windows.

Wearable Electronics

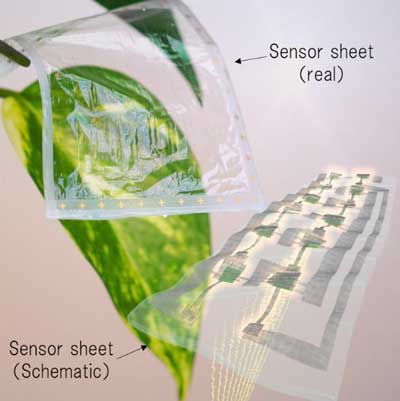

Transparent electronic devices can be integrated into wearable and flexible electronics, such as smart clothing, health monitoring devices, or electronic skin. By using transparent and flexible materials, these devices can be seamlessly embedded into fabrics or attached to the human body, enabling unobtrusive and comfortable monitoring of physiological signals and environmental conditions.

Challenges and Future Perspectives

Despite the significant progress in transparent electronics, several challenges need to be addressed for their widespread adoption. One of the main challenges is the trade-off between electrical conductivity and optical transparency. As the thickness of transparent conductive materials increases to improve conductivity, the transparency often decreases. Researchers are exploring novel materials and nanostructures to optimize this trade-off and achieve high-performance transparent electronics.

Another challenge lies in the scalability and cost-effectiveness of fabrication processes. Many transparent electronic devices rely on expensive materials, such as indium, or require complex and time-consuming fabrication steps. The development of alternative materials, such as conductive polymers and nanomaterials, and the adoption of high-throughput fabrication techniques, like roll-to-roll processing, are crucial for the commercialization of transparent electronics.

Future research in transparent electronics will focus on the development of novel materials with improved optical and electrical properties, the integration of multiple functionalities into a single device, and the exploration of new applications. The combination of transparent electronics with other emerging technologies, such as flexible electronics, energy harvesting, and sensors, will open up exciting opportunities for smart and interactive surfaces, wearable devices, and sustainable energy solutions.

Further Reading

Journal of Materials Chemistry C, Materials and devices for transparent stretchable electronics

Chemical Reviews, Transparent Electronics for Wearable Electronics Application