Nanostructured Materials - Transforming Material Properties at the Nanoscale

What are Nanostructured Materials?

Nanostructured materials are a class of materials that have at least one dimension in the nanoscale range, typically between 1 and 100 nanometers. These materials exhibit unique properties and behaviors that differ from their bulk counterparts due to their high surface area to volume ratio and quantum confinement effects at the nanoscale.

Types of Nanostructured Materials

Nanostructured materials can be classified into several categories based on their dimensions and morphologies:

- Zero-dimensional (0D) nanostructures: These include nanoparticles, quantum dots, and nanoclusters, which have all three dimensions in the nanoscale range.

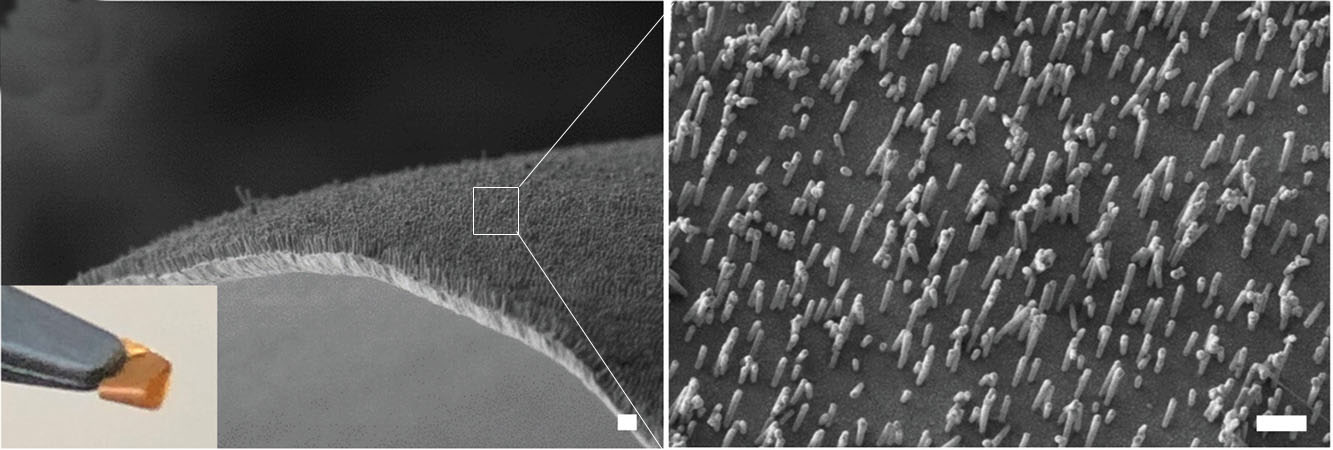

- One-dimensional (1D) nanostructures: These include nanowires, nanotubes, and nanorods, which have two dimensions in the nanoscale range and one dimension extending beyond the nanoscale.

- Two-dimensional (2D) nanostructures: These include thin films, nanosheets, and graphene, which have one dimension in the nanoscale range and two dimensions extending beyond the nanoscale.

- Three-dimensional (3D) nanostructures: These include nanofoams, nanoporous materials, and nanocomposites, which have complex architectures with nanoscale features in all three dimensions.

Synthesis and Fabrication of Nanostructured Materials

Various methods have been developed to synthesize and fabricate nanostructured materials, depending on the desired composition, morphology, and properties. Some common approaches include:

Bottom-up Methods

Bottom-up methods involve the assembly of individual atoms, molecules, or nanobuilding blocks into larger nanostructures. Examples include chemical synthesis, self-assembly, and template-directed synthesis. These methods allow for precise control over the size, shape, and composition of nanostructured materials.

Top-down Methods

Top-down methods involve the patterning or etching of bulk materials to create nanostructures. Examples include lithography, nanoimprint lithography, and focused ion beam milling. These methods are suitable for fabricating nanostructures with well-defined geometries and patterns.

Hybrid Methods

Hybrid methods combine both bottom-up and top-down approaches to create nanostructured materials with complex architectures. For example, nanolithography can be used to create patterns on a substrate, followed by the self-assembly of nanoparticles or molecules within the patterned regions.

Properties and Applications of Nanostructured Materials

Nanostructured materials exhibit unique properties that make them attractive for a wide range of applications:

Electronic and Optical Properties

Nanostructured materials can have enhanced electronic and optical properties due to quantum confinement effects. For example, quantum dots exhibit size-dependent emission colors, making them useful for light-emitting diodes (LEDs), solar cells, and biomedical imaging. Graphene, a 2D nanostructured material, has exceptional electrical conductivity and optical transparency, making it promising for transparent electrodes and high-speed electronics.

Mechanical Properties

Nanostructured materials often exhibit superior mechanical properties compared to their bulk counterparts. For example, carbon nanotubes have exceptional strength and stiffness, making them ideal for reinforcing composite materials. Nanostructured metals and alloys can have enhanced hardness, wear resistance, and fatigue strength due to grain size refinement and surface effects.

Catalytic Properties

Nanostructured materials have high surface area to volume ratios, which makes them attractive for catalytic applications. Nanoparticles of noble metals, such as gold and platinum, have been widely used as catalysts for chemical reactions, fuel cells, and environmental remediation. Nanostructured oxides and zeolites are also employed as catalysts in various industrial processes.

Biomedical Applications

Nanostructured materials have significant potential in biomedical applications, such as drug delivery, tissue engineering, and biosensing. Nanoparticles can be designed to target specific cells or tissues, enabling controlled release of therapeutic agents. Nanostructured scaffolds can mimic the extracellular matrix and promote cell adhesion and growth for tissue regeneration. Nanostructured sensors can detect biomolecules with high sensitivity and selectivity.

Challenges and Future Perspectives

Despite the tremendous progress in nanostructured materials, several challenges remain to be addressed. One of the main challenges is the scalable and cost-effective production of nanostructured materials with precise control over their properties. The development of robust characterization techniques and computational tools is also crucial for understanding the structure-property relationships of nanostructured materials.

Future research in nanostructured materials will focus on the design and synthesis of novel nanostructures with tailored properties for specific applications. The integration of nanostructured materials with other emerging technologies, such as flexible electronics, energy storage, and advanced manufacturing, will open up new opportunities for innovative products and devices. Additionally, the exploration of multifunctional nanostructured materials that combine multiple properties, such as electronic, optical, and mechanical properties, will enable the development of smart and adaptive systems.