| Posted: Dec 18, 2007 | |

Control of structural parameter, rather than constituents, is key to future composite materials |

|

| (Nanowerk Spotlight) Even the smartest scientists can still learn from the dumbest animals - at least as far as materials science is concerned. Take for instance marine glass sponges such as the hexactinellid sponge Euplectella sp. which are considered to be one of the most primitive animals in existence. Nevertheless, they produce integrated composite materials with outstanding mechanical properties and researchers are interested in finding out how they do that and how this natural process could be copied and adapted for use in the fabrication of synthetic composite materials. Euplectella's bioglass filaments, for instance, exhibit a rather complex design, thus ensuring the control of both mechanical and chemical interfaces between the different components to overcome the brittleness of the main constituent material, glass. Scientists have found that the amazing properties of many biological high-performance materials such as bone or shells are a result of the structure and the interplay of the constituents. In other words, the hierarchical structure of composites determines their material properties, and not the type of the composite's constituents. Researchers in Germany have now reported a biomimetic approach for the fast fabrication of hierarchically structured peptide-silica fibers, mimicking the bio-silicification process of natural glass fibers. | |

| "The hierarchical structure of biosilica fibers is controlled by proteins, and hence we have presented a biomimetic approach in which not only the composition and structure of the composite material were mimicked, but also the peptide-guided synthesis" Dr. Hans Börner explains to Nanowerk. "We obtained well-defined composite fibers with hierarchical design and interesting mechanical properties by the directed co-assembly of functional PEO–peptide nanotapes with silica ("Rational design of oligopeptide organizers for the formation of poly(ethylene oxide) nanofibers"). Potentially, this approach advents the synthesis of novel silica materials with purpose-defined structures and adjustable properties." | |

| Börner is a researcher at the Max Planck Institute of Colloids and Interfaces in Potsdam/Germany, where he leads the PolyPeP group (Bioorganic-Synthetic Hybrid Polymers as Molecular LEGO®-Bricks). In a recent paper published in Angewandte Chemie International Edition ("Categorization framework to aid hazard identification of nanomaterials"), Börner and members of his group describe how, by combining self-assembly of peptide-polymer-conjugates with peptide-directed silicification, macroscopic composite fibers were spontaneously formed. | |

|

|

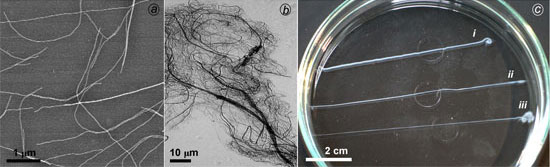

| AFM micrograph of composite nanofibers (a) that show directed self-assembly into composite fiber bundles ((b) light microscopy) and plotted silica-composite fibers ((c) photograph), where the fiber width depends on the rate of plotting (0.5, 1, 2 m/sec respectively, resulting in fiber widths of 70-700 µm). (Images: Dr. Börner/Max Planck Institute of Colloids and Interfaces) | |

| The Max-Planck researchers describe how these fibers exhibit six distinguishable levels of hierarchical order, spanning length scales from the nanometer up to millimeters in lateral and even centimeters in longitudinal dimensions. | |

| "The silicification process indeed does not stop after forming one silica layer around the template molecule, as happens in many other systems utilizing for instance cellulose fibers or carbon nanotubes" says Börner. "Due to synergistic effects, the organization of the resulting nanocomposite tapes proceeds further. Thus, the material is characterized by a complex, but well-defined inner structure." | |

| The scientists controlled the mechanical and chemical interfaces between the different components in the composite fibers they synthesized in order to overcome the brittleness of glass. As a result, they obtained reinforced glass-fibers, exhibiting already 1/3 of the mechanical hardness of natural glass sponge spicules. They were able to enhance elasticity – which is considered a limiting factor in optical glass fibers – four-fold due to the incorporation of an increased amount of peptide-polymer-nanotapes. | |

| This approach demonstrates the interplay between functional peptide-polymer aggregates and inorganic silicification-condensation processes. It clearly shows that the hierarchical organization of the composite material is guided across several length scales by the information, encoded in a rather simple peptide strand of a peptide-polymer conjugate (building block). The composite fibers can be calcined (i.e. thermally treated) to remove the organic components, leading to a silica material with highly ordered pores along the fiber direction over several hundreds of nanometers. | |

| "We believe that this approach is a significant step towards self-assembled biomimetic materials with purpose-defined properties" says Börner. "Similar to biological materials such as bones or mollusk shells, the properties of our synthesized composites are a result of the structure and the interplay of the constituents. We certainly can see a number of future applications for novel silica materials with defined structures and properties. I could envisage membranes of composite fibers or mesoporous silica fabrics, providing materials for regenerative tissue engineering and bioactive ceramics that are designed to interface with living biological systems." | |

| These results highlight the fact that precise control over structure is a key factor in biological and biomimetic materials, which allows the modulation of material properties over a broad range. This could mean that changing and adapting materials in the future might not require the change of constituents but rather a modification of the structural parameters of a composite material. | |

| Börner describes how his team recently was able to establish a plotting process which allowed the drawing of macroscopic composite fibers. "Interestingly, the organization of the inner structure increased, leading to an alignment of sub-micrometer structure elements in the direction of plotting" he says. "Such a plotting process might might one day enable the production of silica composites with virtually every shape." | |

| The rapid plotting of composite fiber networks could be a significant step towards sophisticated production processes using inkjet or 2D-plotting devices. The technique could potentially be adopted to 3D-plotting to manufacture silica-based composite materials that exhibit smartly reinforced structures (similar to natural bone material). | |

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|