Showing Spotlights 385 - 392 of 624 in category All (newest first):

After achieving the 45-nm process, today's semiconductor industry is nearing the 20-nm process and looking for techniques that would enable sub-22-nm-half-pitch line patterns. Following the continuous increase in exposure tool numerical aperture, researchers are pursuing reductions in exposure wavelengths. This effort had them look at extreme ultraviolet (EUV: 13.4 nm in wavelength) as an exposure light source. Unlike the numerical aperture engineering, change of a light source to EUV demands development of its related components, such as photoresist and optics. Until a reliable solution for EUV lithography is developed, EUV interference lithography (EUVIL) would not solely advance the lithographic technology but would also help to optimize photoresist materials for EUV.

After achieving the 45-nm process, today's semiconductor industry is nearing the 20-nm process and looking for techniques that would enable sub-22-nm-half-pitch line patterns. Following the continuous increase in exposure tool numerical aperture, researchers are pursuing reductions in exposure wavelengths. This effort had them look at extreme ultraviolet (EUV: 13.4 nm in wavelength) as an exposure light source. Unlike the numerical aperture engineering, change of a light source to EUV demands development of its related components, such as photoresist and optics. Until a reliable solution for EUV lithography is developed, EUV interference lithography (EUVIL) would not solely advance the lithographic technology but would also help to optimize photoresist materials for EUV.

Jul 8th, 2010

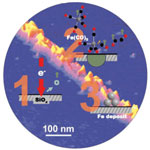

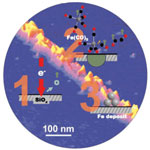

The manufacture of certain types of nanostructures - nanotubes, graphene, nanoparticles, etc. - has already entered industrial-scale mass production. However, the controlled fabrication of nanostructures with arbitrary shape and defined chemical composition is still a major challenge in nanotechnology applications. It appears that electron beams from electron microscopes (EM) - nowadays routinely focused down to the nanometer regime - are ideal candidates for versatile tools for nanotechnology. However, their usage is mostly restricted by the conditions in the corresponding electron microscopes, since most EMs are housed in high vacuum chambers the unintended electron-beam-induced deposition of residual gases is a problem, as well as the maintenance of well defined sample conditions. Researchers in Germany have now presented a novel way to use a highly focused electron beam to lithographically fabricate clean iron nanostructures. This new technique expands the application field for focused electron beams in nanotechnology.

The manufacture of certain types of nanostructures - nanotubes, graphene, nanoparticles, etc. - has already entered industrial-scale mass production. However, the controlled fabrication of nanostructures with arbitrary shape and defined chemical composition is still a major challenge in nanotechnology applications. It appears that electron beams from electron microscopes (EM) - nowadays routinely focused down to the nanometer regime - are ideal candidates for versatile tools for nanotechnology. However, their usage is mostly restricted by the conditions in the corresponding electron microscopes, since most EMs are housed in high vacuum chambers the unintended electron-beam-induced deposition of residual gases is a problem, as well as the maintenance of well defined sample conditions. Researchers in Germany have now presented a novel way to use a highly focused electron beam to lithographically fabricate clean iron nanostructures. This new technique expands the application field for focused electron beams in nanotechnology.

Jun 28th, 2010

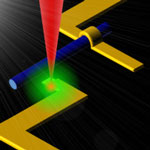

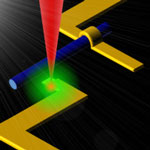

Current fabrication technologies for nanoscale devices include deep-UV or electron-beam (e-beam) lithography. Both of these techniques involve successive deposition of metal or insulating layer and a resist layer, which is patterned using a UV source or a scanning electron beam. The process needs to be repeated for each layer of the architecture while the sample is taken out of the high vacuum chamber. Thus, multilayer lithography processes seriously compromise throughput and cost. In addition, the resolution is limited in the sub-10 nm regime. Researchers at the Institute of Bioengineering and Nanotechnology (IBN) in Singapore have now successfully demonstrated, for the first time, a lithography-free, direct-write technique for fabricating discrete field-effect transistors, as well as digital logic gates on a single nanowire.

Current fabrication technologies for nanoscale devices include deep-UV or electron-beam (e-beam) lithography. Both of these techniques involve successive deposition of metal or insulating layer and a resist layer, which is patterned using a UV source or a scanning electron beam. The process needs to be repeated for each layer of the architecture while the sample is taken out of the high vacuum chamber. Thus, multilayer lithography processes seriously compromise throughput and cost. In addition, the resolution is limited in the sub-10 nm regime. Researchers at the Institute of Bioengineering and Nanotechnology (IBN) in Singapore have now successfully demonstrated, for the first time, a lithography-free, direct-write technique for fabricating discrete field-effect transistors, as well as digital logic gates on a single nanowire.

Jun 16th, 2010

Nanoparticle chirality has attracted much attention among nanoscientists, and the application of chiral nanoparticles in chemistry, biology and medicine is of great importance for the development of new molecular nanosystems. In chemistry, chirality usually refers to molecules. Discovering efficient methods to produce, control and identify enantiomerically pure chiral compounds is critical for the further development of pharmaceuticals, agrochemicals, fragrances and food additives. An important example in the area of nanomaterials is the synthesis of metallic nanoparticles with controlled size, shape, composition, and morphology for catalytic applications.

Nanoparticle chirality has attracted much attention among nanoscientists, and the application of chiral nanoparticles in chemistry, biology and medicine is of great importance for the development of new molecular nanosystems. In chemistry, chirality usually refers to molecules. Discovering efficient methods to produce, control and identify enantiomerically pure chiral compounds is critical for the further development of pharmaceuticals, agrochemicals, fragrances and food additives. An important example in the area of nanomaterials is the synthesis of metallic nanoparticles with controlled size, shape, composition, and morphology for catalytic applications.

Jun 10th, 2010

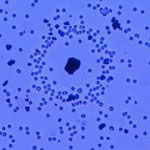

For nanotechnology researchers, movement at the nanoscale is a challenging problem and there is much to be learned from nature's motor systems. There are various approaches to creating self-propelled micro- and nanosized motors and one promising approach rests on catalytic conversion of chemical to mechanical energy - a process that is ubiquitous in biology, powering such important and diverse processes as cell division, skeletal muscle movement, protein synthesis, and transport of cargo within cells. Self-propelled motion of synthetic materials can be useful in applications such as bottom-up assembly of structures, pattern formation, drug delivery at specific locations, etc. Researchers have now presented a novel and versatile light-driven catalytic micromotor system, which is the cleanest and simplest of its kind.

For nanotechnology researchers, movement at the nanoscale is a challenging problem and there is much to be learned from nature's motor systems. There are various approaches to creating self-propelled micro- and nanosized motors and one promising approach rests on catalytic conversion of chemical to mechanical energy - a process that is ubiquitous in biology, powering such important and diverse processes as cell division, skeletal muscle movement, protein synthesis, and transport of cargo within cells. Self-propelled motion of synthetic materials can be useful in applications such as bottom-up assembly of structures, pattern formation, drug delivery at specific locations, etc. Researchers have now presented a novel and versatile light-driven catalytic micromotor system, which is the cleanest and simplest of its kind.

Jun 2nd, 2010

Developing chemicals, molecular precursors, and industrial products from petroleum resources is a conventional practice. Plastics, detergents, even pharmaceuticals are derived from petrochemicals. With an increasing focus on the economic and environmental issues associated with the processing of petroleum-based chemicals, scientists are seeking for alternative routes to develop molecules from naturally available plant or crop-based raw materials. Particularly interesting for the fields of nanotechnology is the design and development of soft nanomaterials from renewable sources. Generating these materials from renewable resources could have a significant impact on production technologies and economies.

Developing chemicals, molecular precursors, and industrial products from petroleum resources is a conventional practice. Plastics, detergents, even pharmaceuticals are derived from petrochemicals. With an increasing focus on the economic and environmental issues associated with the processing of petroleum-based chemicals, scientists are seeking for alternative routes to develop molecules from naturally available plant or crop-based raw materials. Particularly interesting for the fields of nanotechnology is the design and development of soft nanomaterials from renewable sources. Generating these materials from renewable resources could have a significant impact on production technologies and economies.

Jun 1st, 2010

The ability to extract, dispense and manipulate very small amounts of liquids on the micro- and nanoscale is important in biotechnology, chemistry and also for patterning inorganic, organic and biological inks. Several methods for dispensing liquids exist, but many require complicated electrodes and high-voltage circuits. Researchers in Italy have now demonstrated a pyroelectrohydrodynamic droplet dispenser based on pyroelectric forces.Researchers in Italy have developed and demonstrated a completely new method for extracting and dispensing very small amounts of liquid - as small as few attoliters - from liquid droplet reservoirs or thin liquid films by a method called pyroelectrohydrodynamic (Pyro-EHD).

The ability to extract, dispense and manipulate very small amounts of liquids on the micro- and nanoscale is important in biotechnology, chemistry and also for patterning inorganic, organic and biological inks. Several methods for dispensing liquids exist, but many require complicated electrodes and high-voltage circuits. Researchers in Italy have now demonstrated a pyroelectrohydrodynamic droplet dispenser based on pyroelectric forces.Researchers in Italy have developed and demonstrated a completely new method for extracting and dispensing very small amounts of liquid - as small as few attoliters - from liquid droplet reservoirs or thin liquid films by a method called pyroelectrohydrodynamic (Pyro-EHD).

May 18th, 2010

Steel is one of the most widely used engineering materials in the world. Its pre-eminent position amongst the engineering materials arises due to the abundance and low cost of its main constituent, i.e. iron, and its amenability to produce a wide variety of engineered microstructures with superior properties, and recyclability. Currently, there is a growing awareness about the potential benefits of nanotechnology in the modern engineering industry, and a number of leading research institutes and companies are pursuing research in the area of nanostructured steels. The focus of the ongoing efforts has been largely manipulation of microstructures at the nano-scale through innovative processing techniques and adoption of novel alloying strategies.

Steel is one of the most widely used engineering materials in the world. Its pre-eminent position amongst the engineering materials arises due to the abundance and low cost of its main constituent, i.e. iron, and its amenability to produce a wide variety of engineered microstructures with superior properties, and recyclability. Currently, there is a growing awareness about the potential benefits of nanotechnology in the modern engineering industry, and a number of leading research institutes and companies are pursuing research in the area of nanostructured steels. The focus of the ongoing efforts has been largely manipulation of microstructures at the nano-scale through innovative processing techniques and adoption of novel alloying strategies.

May 10th, 2010

After achieving the 45-nm process, today's semiconductor industry is nearing the 20-nm process and looking for techniques that would enable sub-22-nm-half-pitch line patterns. Following the continuous increase in exposure tool numerical aperture, researchers are pursuing reductions in exposure wavelengths. This effort had them look at extreme ultraviolet (EUV: 13.4 nm in wavelength) as an exposure light source. Unlike the numerical aperture engineering, change of a light source to EUV demands development of its related components, such as photoresist and optics. Until a reliable solution for EUV lithography is developed, EUV interference lithography (EUVIL) would not solely advance the lithographic technology but would also help to optimize photoresist materials for EUV.

After achieving the 45-nm process, today's semiconductor industry is nearing the 20-nm process and looking for techniques that would enable sub-22-nm-half-pitch line patterns. Following the continuous increase in exposure tool numerical aperture, researchers are pursuing reductions in exposure wavelengths. This effort had them look at extreme ultraviolet (EUV: 13.4 nm in wavelength) as an exposure light source. Unlike the numerical aperture engineering, change of a light source to EUV demands development of its related components, such as photoresist and optics. Until a reliable solution for EUV lithography is developed, EUV interference lithography (EUVIL) would not solely advance the lithographic technology but would also help to optimize photoresist materials for EUV.

Subscribe to our Nanotechnology Spotlight feed

Subscribe to our Nanotechnology Spotlight feed