Showing Spotlights 377 - 384 of 624 in category All (newest first):

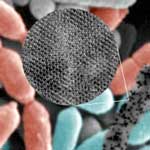

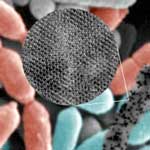

In nature, uni- and multicellular organisms are capable of reducing and accumulating metal ions as detoxification and homeostasis mechanisms when exposed to metal ion solutions. Although the exact mechanisms and identities of microbial proteins associated for metal nanoparticle synthesis are not clear, two cysteine-rich, heavy metal-binding biomolecules, phytochelatin and metallothionein have been relatively well characterized. Phytochelatins are peptides that are synthesized by the protein phytochelatin synthase and that can form metal complexes with cadmium, copper, silver, lead and mercury, while metallothioneins are gene-encoded proteins capable of directly binding metals such as copper, cadmium, and zinc. This capability of phytochelatin and metallothionein - having different metal binding affinities to various metal ions - has now been employed by researchers for the in vivo biosynthesis of metal nanoparticles by recombinant Escherichia coli.

In nature, uni- and multicellular organisms are capable of reducing and accumulating metal ions as detoxification and homeostasis mechanisms when exposed to metal ion solutions. Although the exact mechanisms and identities of microbial proteins associated for metal nanoparticle synthesis are not clear, two cysteine-rich, heavy metal-binding biomolecules, phytochelatin and metallothionein have been relatively well characterized. Phytochelatins are peptides that are synthesized by the protein phytochelatin synthase and that can form metal complexes with cadmium, copper, silver, lead and mercury, while metallothioneins are gene-encoded proteins capable of directly binding metals such as copper, cadmium, and zinc. This capability of phytochelatin and metallothionein - having different metal binding affinities to various metal ions - has now been employed by researchers for the in vivo biosynthesis of metal nanoparticles by recombinant Escherichia coli.

Sep 24th, 2010

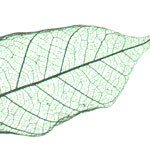

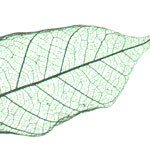

Nature can provide very useful templates for technical applications. A group of scientists have devised a new process involving the almost complete conversion of a leaf skeleton into magnetic iron carbide. To do this, they treated the leaf with iron acetate, nitrogen and heat. This technique can be used to recreate all natural carbonaceous structures with metal carbides. The result is not just beautiful, but also very useful. The new technique enables the conversion of metal carbides into intricate microstructures in just one step. Biology's intricate forms provide a wide range of templates for a variety of applications. Wide-ranging biological forms can be used as templates for filigree metal carbide structures using this method.

Nature can provide very useful templates for technical applications. A group of scientists have devised a new process involving the almost complete conversion of a leaf skeleton into magnetic iron carbide. To do this, they treated the leaf with iron acetate, nitrogen and heat. This technique can be used to recreate all natural carbonaceous structures with metal carbides. The result is not just beautiful, but also very useful. The new technique enables the conversion of metal carbides into intricate microstructures in just one step. Biology's intricate forms provide a wide range of templates for a variety of applications. Wide-ranging biological forms can be used as templates for filigree metal carbide structures using this method.

Sep 22nd, 2010

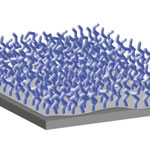

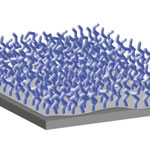

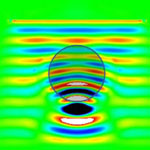

Unlike most biological membranes, polymeric, nanometer-thin membranes are very stable and can withstand considerable pressure. This is an essential requirements for separation processes such as in water purification and desalination. Because their mechanical stability can be combined with flexibility and chemical functionality, polymer nanomembranes are also intensely researchers as materials for actuators and microsensors. They have also entered the biomedical field as artificial nacre and as a novel material used in surgery. Crosslinking of a spin-coated precursor solution, a common fabrication technique, reduces the interactions between the polymer chains and the environment and thus impairs the sensitivity and flexibility of the films. Researchers in Germany have now developed the first freestanding polymer brush, grafted from a crosslinked monolayer (nanosheet) that provides mechanical stability and structural integrity.

Unlike most biological membranes, polymeric, nanometer-thin membranes are very stable and can withstand considerable pressure. This is an essential requirements for separation processes such as in water purification and desalination. Because their mechanical stability can be combined with flexibility and chemical functionality, polymer nanomembranes are also intensely researchers as materials for actuators and microsensors. They have also entered the biomedical field as artificial nacre and as a novel material used in surgery. Crosslinking of a spin-coated precursor solution, a common fabrication technique, reduces the interactions between the polymer chains and the environment and thus impairs the sensitivity and flexibility of the films. Researchers in Germany have now developed the first freestanding polymer brush, grafted from a crosslinked monolayer (nanosheet) that provides mechanical stability and structural integrity.

Sep 2nd, 2010

Along with control of fire, iron smelting is one of the founding technological pillars of civilization. Industry has used the same basic process to make iron for over 3000 years. Yet, it is also one of the major global sources of greenhouse gas release. Iron, a basic commodity, is still produced by the greenhouse gas intensive reduction of iron oxide by carbon-coke and currently accounts for the release of one quarter of worldwide carbon dioxide emissions by industry. For instance, on average 1.9 tonnes of carbon dioxide are emitted for every tonne of steel produced. Due to a large share of coal in the energy mix of current production technology, the CO2 emissions are high. Through a new understanding of the chemistry of iron at high temperature, researchers have uncovered an effective new carbon-dioxide-free process to form iron.

Along with control of fire, iron smelting is one of the founding technological pillars of civilization. Industry has used the same basic process to make iron for over 3000 years. Yet, it is also one of the major global sources of greenhouse gas release. Iron, a basic commodity, is still produced by the greenhouse gas intensive reduction of iron oxide by carbon-coke and currently accounts for the release of one quarter of worldwide carbon dioxide emissions by industry. For instance, on average 1.9 tonnes of carbon dioxide are emitted for every tonne of steel produced. Due to a large share of coal in the energy mix of current production technology, the CO2 emissions are high. Through a new understanding of the chemistry of iron at high temperature, researchers have uncovered an effective new carbon-dioxide-free process to form iron.

Aug 25th, 2010

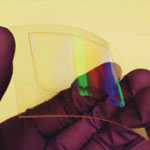

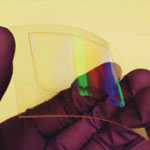

Molding - a manufacturing technique that dates back to the Bronze Age - also has found applications in nanofabrication techniques in the production of high-density optical and magnetic storage media, organic light-emitting diodes, polymer photovoltaic cells, and field-effect transistors. The basic idea of molding is to shape a pliable raw material such as plastic, glass or metal into a desired form by filling it into the mold. Whether it is on the macro- or nanoscale, most molding methods are limited to replicate the patterns that are identical to the original master. To pattern different structures, new masters are needed for every different structure. Researchers have now developed an all-moldable nanofabrication platform that can generate, from a single master, nanoscale patterns with programmable densities, fill factors, and lattice symmetries. They have named this technique solvent-assisted nanoscale embossing (SANE).

Molding - a manufacturing technique that dates back to the Bronze Age - also has found applications in nanofabrication techniques in the production of high-density optical and magnetic storage media, organic light-emitting diodes, polymer photovoltaic cells, and field-effect transistors. The basic idea of molding is to shape a pliable raw material such as plastic, glass or metal into a desired form by filling it into the mold. Whether it is on the macro- or nanoscale, most molding methods are limited to replicate the patterns that are identical to the original master. To pattern different structures, new masters are needed for every different structure. Researchers have now developed an all-moldable nanofabrication platform that can generate, from a single master, nanoscale patterns with programmable densities, fill factors, and lattice symmetries. They have named this technique solvent-assisted nanoscale embossing (SANE).

Aug 23rd, 2010

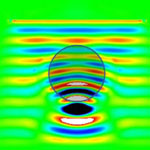

A problem with conventional photolithography techniques is that they cannot achieve the small size requirement of nanoholes and nanopillars, required for various nanofabrication applications, because of the wavelength limitation of the exposure light source. Other nanolithography techniques, such as electron-beam lithography, focused ion beam milling, and x-ray lithography, have the high resolution to form these nanoholes and nanopillars. However, these techniques are all very expensive or have too low a throughput to fabricate a large area of repetitive nanopatterns. A low cost nanosphere lithography method for patterning and generation of semiconductor nanostructures provides a potential alternative to conventional top-down fabrication techniques.

A problem with conventional photolithography techniques is that they cannot achieve the small size requirement of nanoholes and nanopillars, required for various nanofabrication applications, because of the wavelength limitation of the exposure light source. Other nanolithography techniques, such as electron-beam lithography, focused ion beam milling, and x-ray lithography, have the high resolution to form these nanoholes and nanopillars. However, these techniques are all very expensive or have too low a throughput to fabricate a large area of repetitive nanopatterns. A low cost nanosphere lithography method for patterning and generation of semiconductor nanostructures provides a potential alternative to conventional top-down fabrication techniques.

Aug 16th, 2010

Sophisticated molecular-size motors have evolved in nature, where they are used in virtually every important biological process. Some fascinating examples in nature are DNA and RNA polymerase, rotary motors such as ATP synthase, and flagella motors. In contrast, the development of synthetic nanomotors that mimic the function of these amazing natural systems and could be used in man-made nanodevices is in its infancy. Nevertheless, scientists are making good progress in achieving cargo transport by artificial nanomachines although often these advances are handicapped by several drawbacks. Researchers in Germany have now demonstrated the directed loading and transport of microobjects by high propulsion powered tubular microbots driven by a microbubble propulsion mechanism.

Sophisticated molecular-size motors have evolved in nature, where they are used in virtually every important biological process. Some fascinating examples in nature are DNA and RNA polymerase, rotary motors such as ATP synthase, and flagella motors. In contrast, the development of synthetic nanomotors that mimic the function of these amazing natural systems and could be used in man-made nanodevices is in its infancy. Nevertheless, scientists are making good progress in achieving cargo transport by artificial nanomachines although often these advances are handicapped by several drawbacks. Researchers in Germany have now demonstrated the directed loading and transport of microobjects by high propulsion powered tubular microbots driven by a microbubble propulsion mechanism.

Aug 3rd, 2010

Biomechanical energy is one of the main energy components in biological systems. Developing an effective technique that can convert biomechanical energy into electricity is important for the future of in vivo implantable biosensors and other nanomedical devices. Researchers have already shown the conversion of biomechanical energy into electricity by a muscle-movement-driven nanogenerator to harvest mechanical energy from body movement under in vitro conditions. In a first demonstration of using nanotechnology to convert tiny physical motion into electricity in an in vivo environment, the same team has now reported the implanting of a nanogenerator in a live rat to harvest energy generated by its breath and heartbeat.

Biomechanical energy is one of the main energy components in biological systems. Developing an effective technique that can convert biomechanical energy into electricity is important for the future of in vivo implantable biosensors and other nanomedical devices. Researchers have already shown the conversion of biomechanical energy into electricity by a muscle-movement-driven nanogenerator to harvest mechanical energy from body movement under in vitro conditions. In a first demonstration of using nanotechnology to convert tiny physical motion into electricity in an in vivo environment, the same team has now reported the implanting of a nanogenerator in a live rat to harvest energy generated by its breath and heartbeat.

Jul 9th, 2010

In nature, uni- and multicellular organisms are capable of reducing and accumulating metal ions as detoxification and homeostasis mechanisms when exposed to metal ion solutions. Although the exact mechanisms and identities of microbial proteins associated for metal nanoparticle synthesis are not clear, two cysteine-rich, heavy metal-binding biomolecules, phytochelatin and metallothionein have been relatively well characterized. Phytochelatins are peptides that are synthesized by the protein phytochelatin synthase and that can form metal complexes with cadmium, copper, silver, lead and mercury, while metallothioneins are gene-encoded proteins capable of directly binding metals such as copper, cadmium, and zinc. This capability of phytochelatin and metallothionein - having different metal binding affinities to various metal ions - has now been employed by researchers for the in vivo biosynthesis of metal nanoparticles by recombinant Escherichia coli.

In nature, uni- and multicellular organisms are capable of reducing and accumulating metal ions as detoxification and homeostasis mechanisms when exposed to metal ion solutions. Although the exact mechanisms and identities of microbial proteins associated for metal nanoparticle synthesis are not clear, two cysteine-rich, heavy metal-binding biomolecules, phytochelatin and metallothionein have been relatively well characterized. Phytochelatins are peptides that are synthesized by the protein phytochelatin synthase and that can form metal complexes with cadmium, copper, silver, lead and mercury, while metallothioneins are gene-encoded proteins capable of directly binding metals such as copper, cadmium, and zinc. This capability of phytochelatin and metallothionein - having different metal binding affinities to various metal ions - has now been employed by researchers for the in vivo biosynthesis of metal nanoparticles by recombinant Escherichia coli.

Subscribe to our Nanotechnology Spotlight feed

Subscribe to our Nanotechnology Spotlight feed