Showing Spotlights 1409 - 1416 of 2784 in category All (newest first):

When a nanomaterial enters a biological environment, it comes into contact with a complex mixture of proteins. Some of these proteins can adhere to the surface of the nanomaterial, forming a protein 'corona' that influences its subsequent biological interactions. While a number of studies have characterized the protein corona formed around nanomaterials with diameters greater than 10nm, until now, lack of a suitable separation technique has prevented researchers from studying the protein corona formed around 'ultrasmall' nanomaterials. A team of European researchers used electrophoresis to separate ultrasmall nanomaterials from free protein. Applying this technique, they discovered that ultrasmall nanomaterials interact with proteins in a way that is fundamentally different from larger nanomaterials with analogous composition.

When a nanomaterial enters a biological environment, it comes into contact with a complex mixture of proteins. Some of these proteins can adhere to the surface of the nanomaterial, forming a protein 'corona' that influences its subsequent biological interactions. While a number of studies have characterized the protein corona formed around nanomaterials with diameters greater than 10nm, until now, lack of a suitable separation technique has prevented researchers from studying the protein corona formed around 'ultrasmall' nanomaterials. A team of European researchers used electrophoresis to separate ultrasmall nanomaterials from free protein. Applying this technique, they discovered that ultrasmall nanomaterials interact with proteins in a way that is fundamentally different from larger nanomaterials with analogous composition.

Nov 2nd, 2012

The ideal drug carrier may be something out of science fiction. In principle, it is injected into the body and transports itself to the correct target, such as a tumor, and delivers the required dose at this target. This idealized concept was first proposed by Paul Ehrlich at the beginning of the 20th century and was nicknamed the 'magic bullet' concept. With the advent of nanotechnology and nanomedicine this dream is rapidly becoming a reality. Researchers have already demonstrated that unctionalized carbon nanotubes (CNTs) might be able to target specific cells, become ingested, and then release their contents in response to a chemical trigger. A group of researchers has now essentially achieved this goal. They have encapsulated drugs inside carbon nanotubes for drug delivery and shown that these drugs can be released 'on command' by inductive heating with an external alternating current or pulsed magnetic field.

The ideal drug carrier may be something out of science fiction. In principle, it is injected into the body and transports itself to the correct target, such as a tumor, and delivers the required dose at this target. This idealized concept was first proposed by Paul Ehrlich at the beginning of the 20th century and was nicknamed the 'magic bullet' concept. With the advent of nanotechnology and nanomedicine this dream is rapidly becoming a reality. Researchers have already demonstrated that unctionalized carbon nanotubes (CNTs) might be able to target specific cells, become ingested, and then release their contents in response to a chemical trigger. A group of researchers has now essentially achieved this goal. They have encapsulated drugs inside carbon nanotubes for drug delivery and shown that these drugs can be released 'on command' by inductive heating with an external alternating current or pulsed magnetic field.

Oct 30th, 2012

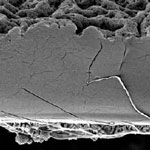

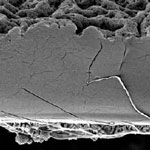

In order to fabricate stimuli-responsive materials, researchers have shown a lot of interest in asymmetric materials such as modulated gels which consist of a controlled layer that is responsive to an environmental stimuli and a nonresponsive substrate layer. And while much effort has gone into creating free-standing films through layer-by-layer (LbL) assembly, relatively little attention has been paid to the asymmetric properties or functionalization of the two surfaces of such free-standing layer-by-layer films. In new work, researchers have now reported the fabrication of asymmetric free-standing layer-by-layer film with asymmetric wettability - one surface is superhydrophobic and the other one is hydrophilic. The superhydrophobic side is water-repellent while the hydrophilic side can absorb/desorb water easily.

In order to fabricate stimuli-responsive materials, researchers have shown a lot of interest in asymmetric materials such as modulated gels which consist of a controlled layer that is responsive to an environmental stimuli and a nonresponsive substrate layer. And while much effort has gone into creating free-standing films through layer-by-layer (LbL) assembly, relatively little attention has been paid to the asymmetric properties or functionalization of the two surfaces of such free-standing layer-by-layer films. In new work, researchers have now reported the fabrication of asymmetric free-standing layer-by-layer film with asymmetric wettability - one surface is superhydrophobic and the other one is hydrophilic. The superhydrophobic side is water-repellent while the hydrophilic side can absorb/desorb water easily.

Oct 29th, 2012

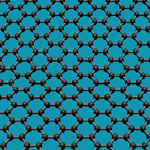

Sensitive electronic devices like cell phones and computers require shielding from electromagnetic interference (EMI). Such shielding - which must be electrically conductive - has traditionally been made of metal, which poses a weight problem in the push to miniaturize and lighten electronics. Previous research has already demonstrated that ultra-lightweight carbon nanostructure-based nanocomposite materials outperform conventional metal shielding due to their light weight, resistance to corrosion, flexibility, and processing advantages. In new work, scientists in Korea have now demonstrated that single-layer graphene is an excellent choice of material for high-performance EMI shielding. They found that CVD-synthesized graphene shows more than seven times greater EMI shielding effectiveness (in terms of dB) than gold film of the same thickness.

Sensitive electronic devices like cell phones and computers require shielding from electromagnetic interference (EMI). Such shielding - which must be electrically conductive - has traditionally been made of metal, which poses a weight problem in the push to miniaturize and lighten electronics. Previous research has already demonstrated that ultra-lightweight carbon nanostructure-based nanocomposite materials outperform conventional metal shielding due to their light weight, resistance to corrosion, flexibility, and processing advantages. In new work, scientists in Korea have now demonstrated that single-layer graphene is an excellent choice of material for high-performance EMI shielding. They found that CVD-synthesized graphene shows more than seven times greater EMI shielding effectiveness (in terms of dB) than gold film of the same thickness.

Oct 25th, 2012

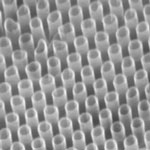

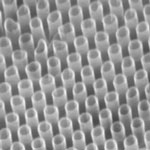

Nanostructured surfaces with special wetting properties can not only efficiently repel or attract liquids like water and oils but can also prevent formation of biofilms, ice, and other detrimental crystals. Such super- and ultrahydrophobic surfaces also hold the promise of significantly improving performance of condensers, which could boost the efficiency of most power plants in the world. A critical part of designing such surfaces is 'seeing' how water and other liquids interact when in contact with them. Since these surfaces are made of nanostructures, scientists need to use an electron microscope to image these interactions. In new work, researchers have developed a method for directly imaging such interfacial regions with previously unattainable nanoscale resolution.

Nanostructured surfaces with special wetting properties can not only efficiently repel or attract liquids like water and oils but can also prevent formation of biofilms, ice, and other detrimental crystals. Such super- and ultrahydrophobic surfaces also hold the promise of significantly improving performance of condensers, which could boost the efficiency of most power plants in the world. A critical part of designing such surfaces is 'seeing' how water and other liquids interact when in contact with them. Since these surfaces are made of nanostructures, scientists need to use an electron microscope to image these interactions. In new work, researchers have developed a method for directly imaging such interfacial regions with previously unattainable nanoscale resolution.

Oct 24th, 2012

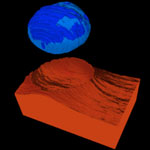

A new report, which reviews the history of nanotechnology research and development at NASA over the past 15 years, shows that NASA is the only U.S. federal agency to scale back investment in this area. The study argues that nanotechnology has the proven capability of revolutionizing most areas of technology that will be critical to NASA's future missions: The agency needs a bolder plan for R+D to match the requirements of those missions and to recapture its place at the forefront of nanotechnology. But it's not as if NASA doesn't have any ideas as to how nanotechnologies could be used to advance space technologies. In 2010, the agency drafted a 20-year Nanotechnology Roadmap as part of its integrated Space Technology Roadmap. According to this document, nanotechnology can have a broad impact on NASA missions.

A new report, which reviews the history of nanotechnology research and development at NASA over the past 15 years, shows that NASA is the only U.S. federal agency to scale back investment in this area. The study argues that nanotechnology has the proven capability of revolutionizing most areas of technology that will be critical to NASA's future missions: The agency needs a bolder plan for R+D to match the requirements of those missions and to recapture its place at the forefront of nanotechnology. But it's not as if NASA doesn't have any ideas as to how nanotechnologies could be used to advance space technologies. In 2010, the agency drafted a 20-year Nanotechnology Roadmap as part of its integrated Space Technology Roadmap. According to this document, nanotechnology can have a broad impact on NASA missions.

Oct 23rd, 2012

By exploiting the outstanding properties of self-organizing materials, a team of Italian scientists has investigated a new way to build a bridge between two branches of physics: 'hard matter' and 'soft matter'. This allows researchers to address specific issues towards the realization of active-plasmonics devices, where the plasmonic resonance of gold nanoparticles can be finely controlled by means of external perturbations (electrical field, optical field, temperature). In place of a static approach - e.g. varying particles size, materials, etc. - the researchers used liquid crystals as active surrounding medium. This approach represents a 'scientific wedding' between the fascinating worlds of soft matter and plasmonics worlds.

By exploiting the outstanding properties of self-organizing materials, a team of Italian scientists has investigated a new way to build a bridge between two branches of physics: 'hard matter' and 'soft matter'. This allows researchers to address specific issues towards the realization of active-plasmonics devices, where the plasmonic resonance of gold nanoparticles can be finely controlled by means of external perturbations (electrical field, optical field, temperature). In place of a static approach - e.g. varying particles size, materials, etc. - the researchers used liquid crystals as active surrounding medium. This approach represents a 'scientific wedding' between the fascinating worlds of soft matter and plasmonics worlds.

Oct 22nd, 2012

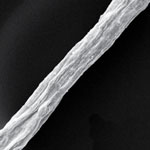

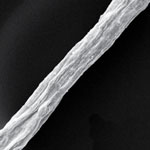

Nanoscale materials like quantum dots, carbon nanotubes, graphene, or nanowires, have intriguing properties, but unless they can be assembled in to larger structures it is difficult to take advantage of these properties. Figuring out how to assemble nanostructures into functional macroscale assemblies is one of the key challenges that nanoscientists around the world are faced with. In the area of nanowires, this has led to researchers exploring various nanowire assembly techniques ranging from Langmuir Blodgett alignment to electrospinning. Researchers have now developed a novel approach for assembling nanowires into macroscopic yarns that consist of millions of nanowires bundled together. The team found that light can be used to charge inorganic semiconducting nanowires. Once charged, the nanowires can be manipulated with electric fields.

Nanoscale materials like quantum dots, carbon nanotubes, graphene, or nanowires, have intriguing properties, but unless they can be assembled in to larger structures it is difficult to take advantage of these properties. Figuring out how to assemble nanostructures into functional macroscale assemblies is one of the key challenges that nanoscientists around the world are faced with. In the area of nanowires, this has led to researchers exploring various nanowire assembly techniques ranging from Langmuir Blodgett alignment to electrospinning. Researchers have now developed a novel approach for assembling nanowires into macroscopic yarns that consist of millions of nanowires bundled together. The team found that light can be used to charge inorganic semiconducting nanowires. Once charged, the nanowires can be manipulated with electric fields.

Oct 18th, 2012

When a nanomaterial enters a biological environment, it comes into contact with a complex mixture of proteins. Some of these proteins can adhere to the surface of the nanomaterial, forming a protein 'corona' that influences its subsequent biological interactions. While a number of studies have characterized the protein corona formed around nanomaterials with diameters greater than 10nm, until now, lack of a suitable separation technique has prevented researchers from studying the protein corona formed around 'ultrasmall' nanomaterials. A team of European researchers used electrophoresis to separate ultrasmall nanomaterials from free protein. Applying this technique, they discovered that ultrasmall nanomaterials interact with proteins in a way that is fundamentally different from larger nanomaterials with analogous composition.

When a nanomaterial enters a biological environment, it comes into contact with a complex mixture of proteins. Some of these proteins can adhere to the surface of the nanomaterial, forming a protein 'corona' that influences its subsequent biological interactions. While a number of studies have characterized the protein corona formed around nanomaterials with diameters greater than 10nm, until now, lack of a suitable separation technique has prevented researchers from studying the protein corona formed around 'ultrasmall' nanomaterials. A team of European researchers used electrophoresis to separate ultrasmall nanomaterials from free protein. Applying this technique, they discovered that ultrasmall nanomaterials interact with proteins in a way that is fundamentally different from larger nanomaterials with analogous composition.

Subscribe to our Nanotechnology Spotlight feed

Subscribe to our Nanotechnology Spotlight feed